Cable clamp dragging device of coal cutter

A technology of dragging device and cable clamp, which is applied in the direction of cable laying equipment, etc., can solve the problems of gas combustion and explosion, strong cable clamp force, threat to mine safety, etc., achieve small transformation workload, reduce labor intensity, and reduce production cost Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The technical solutions of the present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

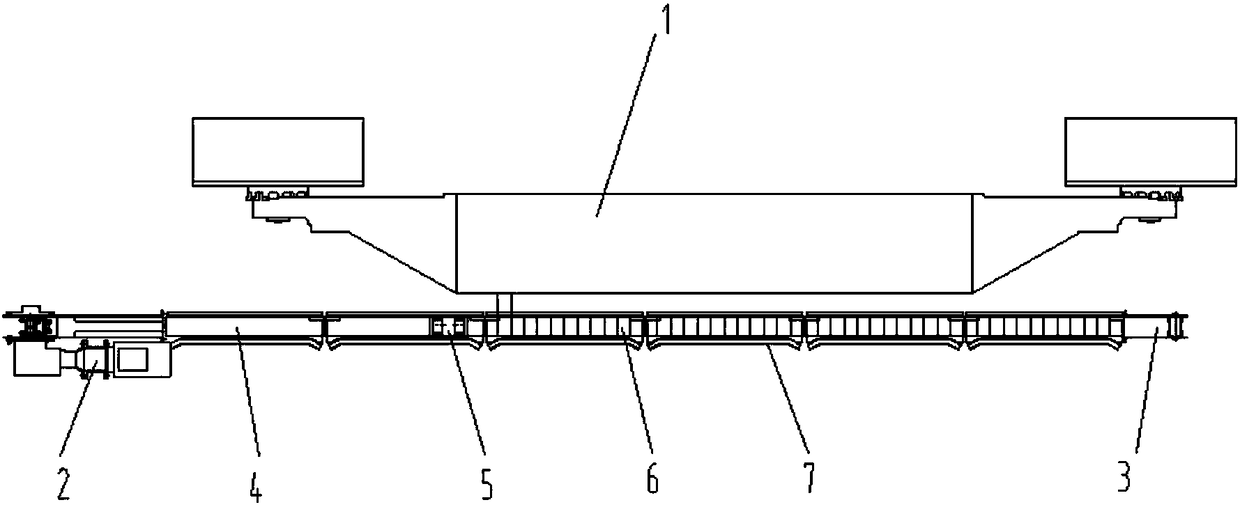

[0025] Such as Figure 1-5 As shown, the scraper conveyor has a cable groove 7 for storing cable clamps. The cable clamp dragging device of the coal shearer includes a driving machine head 2, a rotary machine tail 3, a pulling device part 5 and a bracket. In the embodiment of the present invention, the bracket includes a fixing frame 12 and a supporting frame 13, and the fixing frame 12 and the supporting frame 13 may be integrated or two independent parts.

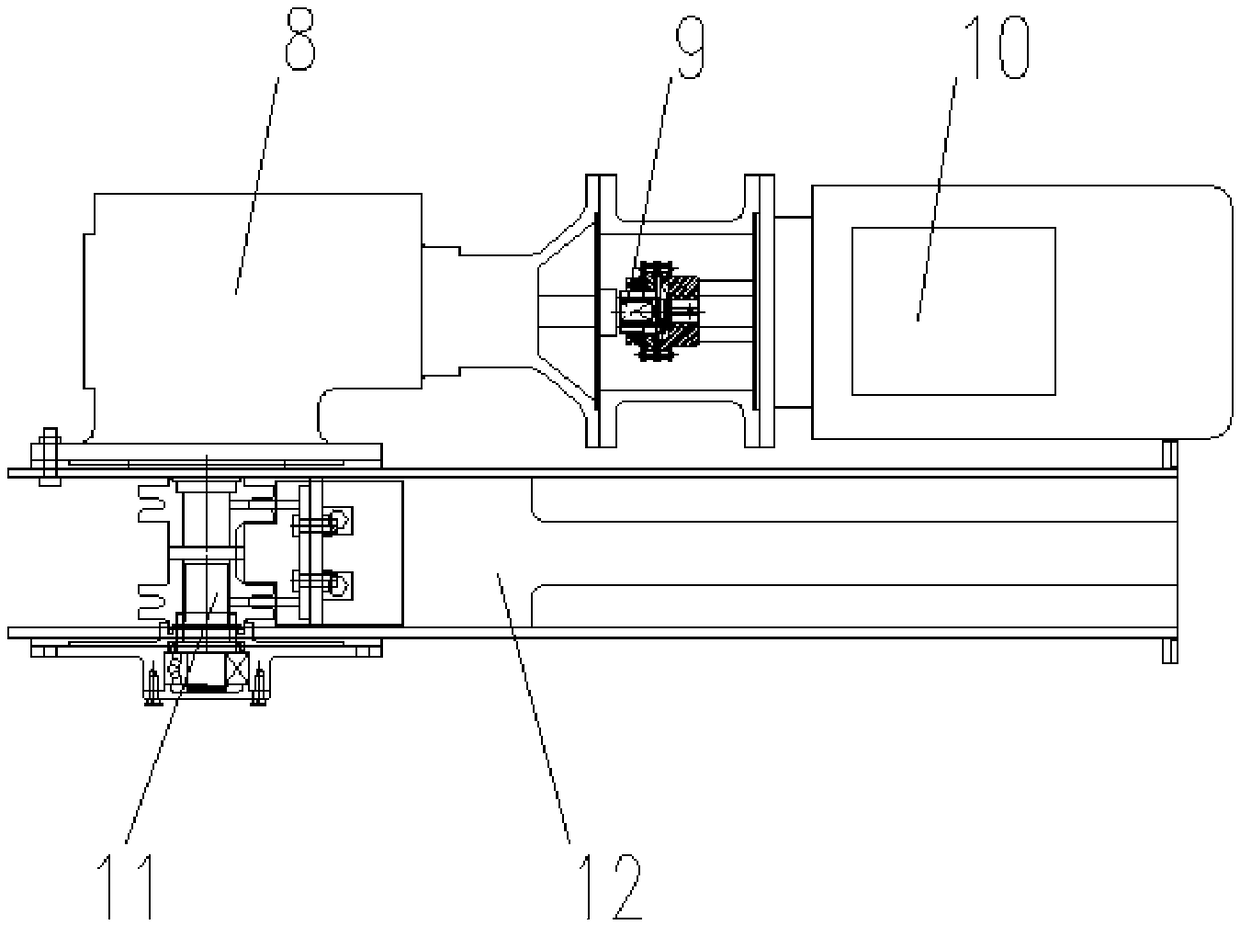

[0026] The driving machine head 2 comprises a driving motor 10 and a driving sprocket 11; the driving motor 10 and the driving sprocket 11 are installed on the fixed frame 12 respectively, and the driving motor 10 drives the driving sprocket 11 to rotate;

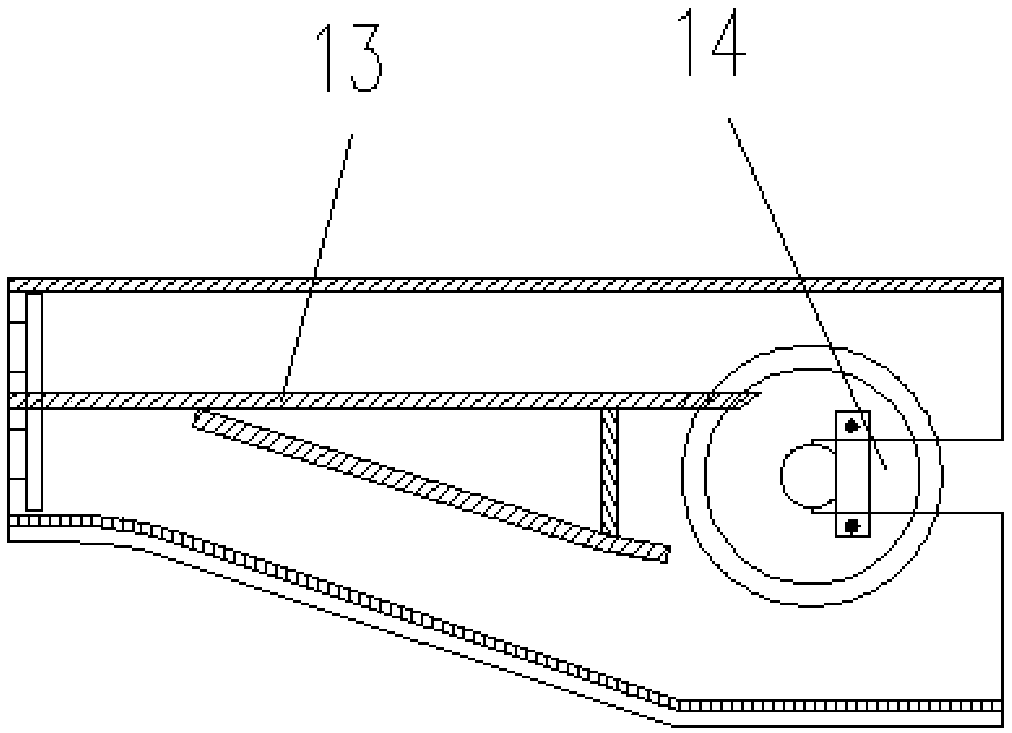

[0027] The tail part 3 of the rotary machine includes a rotary sprocket 14, which is rotatably mounted ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com