A Portable Curved Surface Material Grooving Machine

A slotting machine and portable technology, applied in stone processing equipment, stone processing tools, metal processing machinery parts, etc., can solve the problems of poor portability, high labor intensity, low yield rate, etc., to reduce labor intensity and improve processing efficiency , Guarantee the effect of moving towards regularity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment example 1

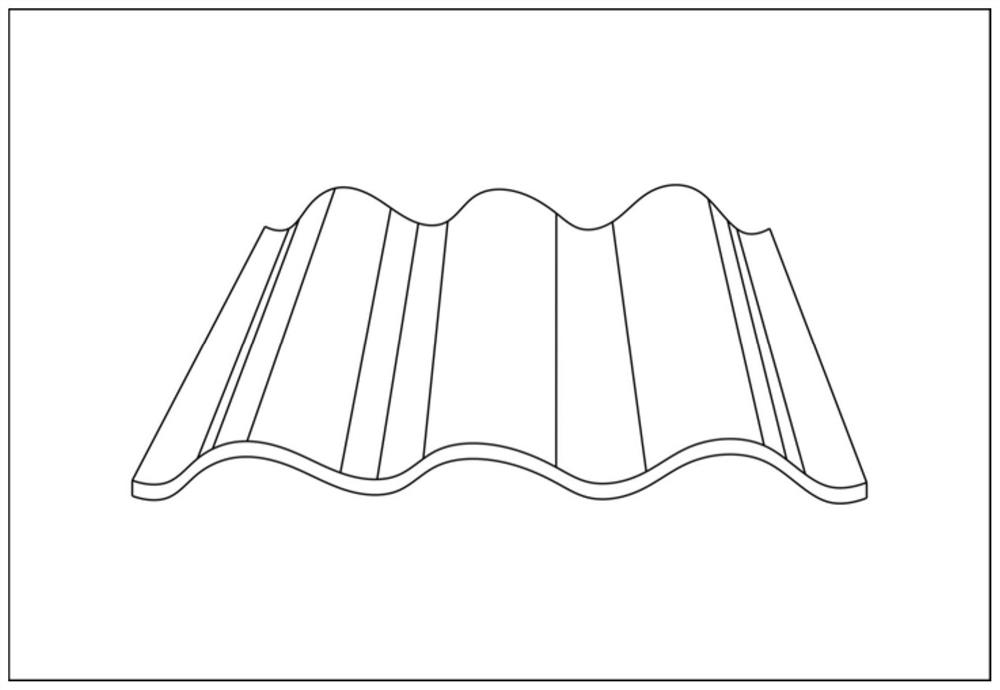

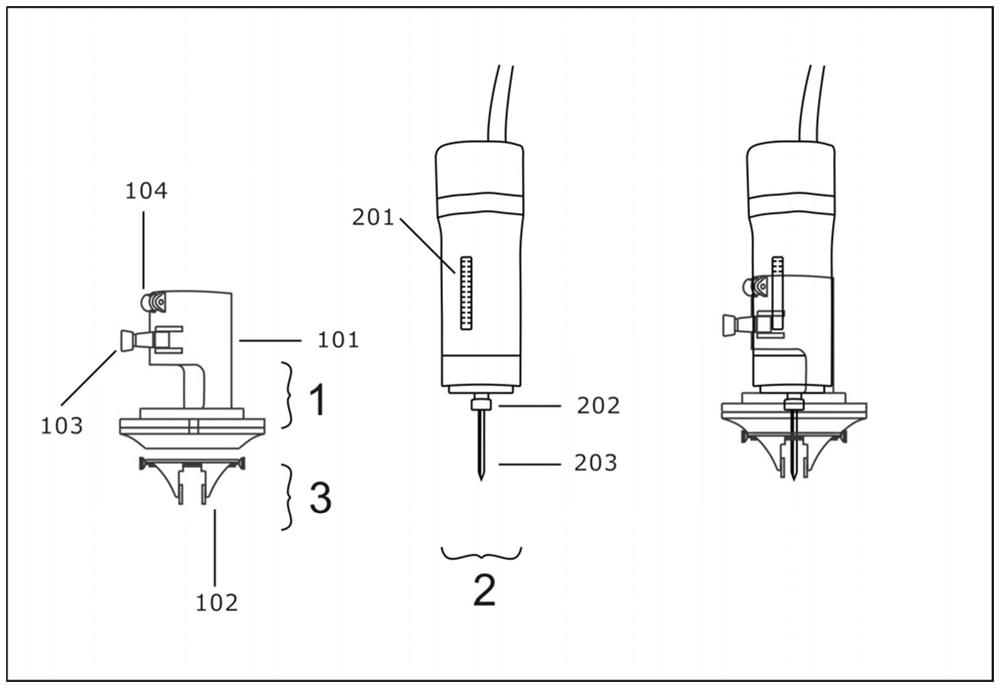

[0028] The slotting machine of the present invention is such as figure 1 The working process of common types of curved surface materials is as follows:

[0029] Step 1: Install the slotting cutter on the slotting cutter holder 202 under the power motor 2.

[0030] Step 2: Measure the outer diameter of the grooving tool used, and turn the knob 303 to adjust the threaded screw 302, so that the distance between the curved arc follow-up device 105 is slightly larger than the outer diameter of the tool.

[0031] Step 3: Open the clamp 103 on the fixed sleeve 101 on the frame 1, install the power motor 2 with cutter into the sleeve 101, refer to the grooved depth fine-tuning ruler 201 on the side of the power motor 2, and turn it up and down The grooving depth fine-adjusting rubber roller 104 finely adjusts the extension of the extension support 102 of the grooving tool to reach the grooving demand, and the clamp 103 is locked.

[0032] The fourth step: such as Picture 8 As shown, the tool...

Embodiment example 2

[0035] The slotting machine of the present invention is such as figure 1 The working process of small radian diameter curved surface materials is as follows:

[0036] Step 1: Rotate the knob 303 on the curved surface arc follow-up mechanism assembly 3 to increase the distance between the two support frames 102 to expose the support frame fixing screws 304, remove the 4 support frame fixing screws 304, and extend the extension 106 Install it between the frame 1 and the curved arc follow-up mechanism 3, and fix it with 4 support frame extension fixing screws 305, such as Image 6 Shown; such as Figure 7 As shown, when processing small radian-diameter curved surface materials, if there is no extension section, it is easy to cause the curved surface material itself to interfere with the frame and the situation that it cannot be slotted, such as Figure 7 The situation shown by the cross, plus the extension 106, can completely avoid this situation, such as Figure 7 As shown in the che...

Embodiment example 3

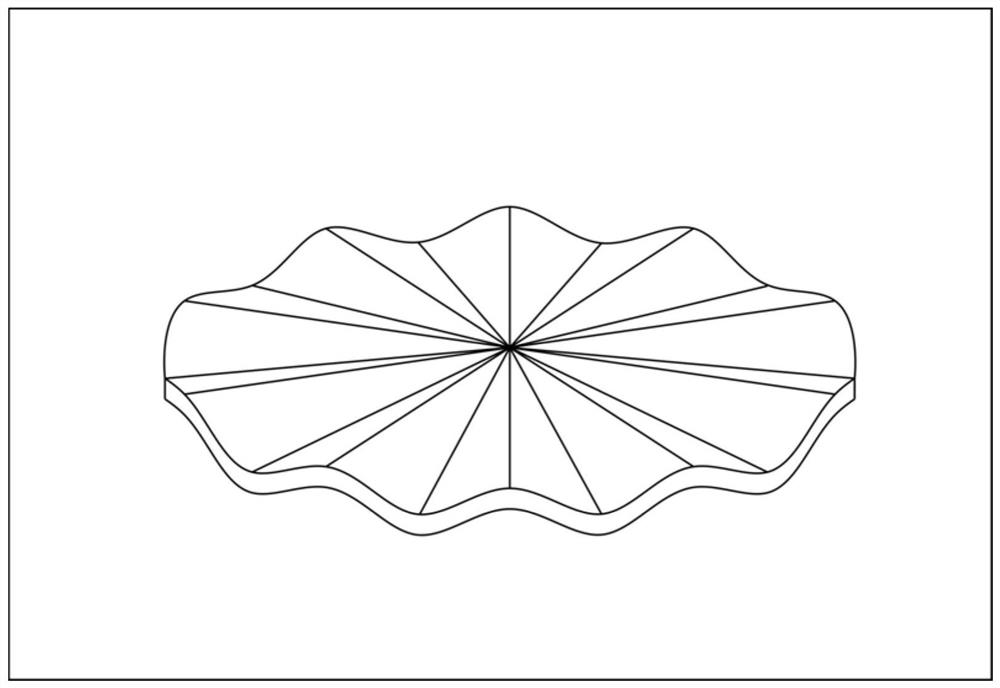

[0042] The slotting machine of the present invention is such as figure 2 The working process of the curved surface material with the type arc radial arrangement is as follows:

[0043] The first step: install the slotting cutting tool on the slotting cutting tool holder 202 under the power motor 2.

[0044] Step 2: Measure the outer diameter of the grooving tool used, and rotate the knob 303 on the curved arc follow-up mechanism 3 to adjust the threaded screw 302 so that the distance between the curved curved follow-up device 105 is slightly larger than the outer diameter of the tool.

[0045] Step 3: Open the fixed sleeve clamp 103 on the frame 1, install the power motor 2 with cutter into the sleeve 101, refer to the groove depth fine-adjusting ruler 201 on the side of the power motor 2, and turn the groove depth up and down The fine adjustment rubber roller 104 finely adjusts the extension of the extension support 102 of the grooving tool to meet the grooving requirement, and the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com