A method of manufacturing a controllable antibacterial tracheal stent

A technology of tracheal stent and manufacturing method, which is applied in the field of manufacture of controllable antibacterial tracheal stent, and can solve problems such as repeated airway infection, lack of cellular immune function, and endangering the lives of patients

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

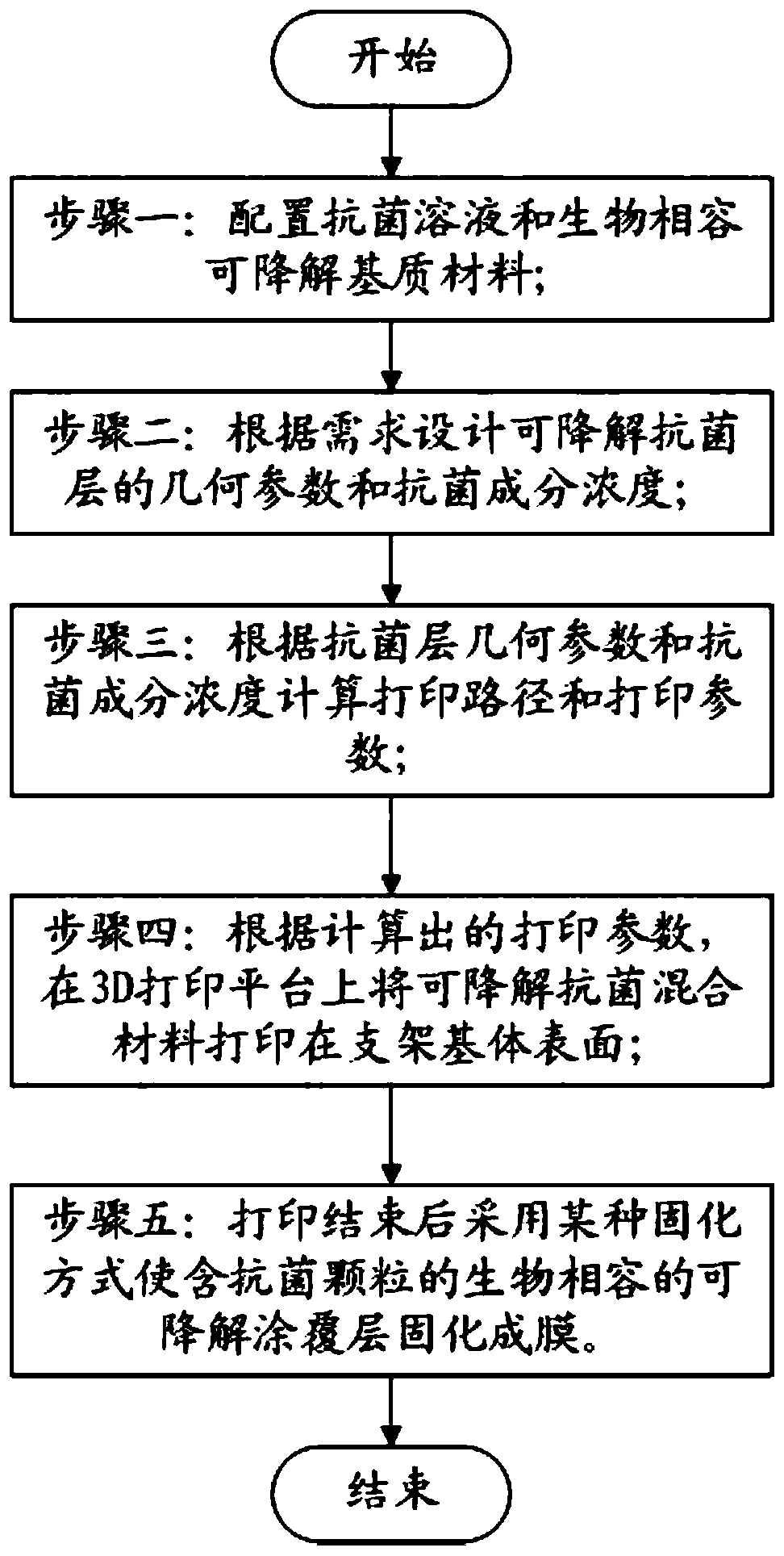

[0036] like figure 1 As shown, the method for manufacturing a controllable antibacterial tracheal stent in this embodiment includes the following steps:

[0037] Step 1: configure an antibacterial solution (such as nano-silver solution) and a biocompatible degradable matrix material (such as a mixed solution of chitosan and gelatin);

[0038] Step 2: Determine the geometric parameters of the degradable antibacterial layer and the concentration of antibacterial components according to the needs;

[0039] Step 3: Calculate the printing path and printing parameters according to the geometric parameters of the antibacterial layer and the concentration of antibacterial components;

[0040] Step 4: According to the calculated printing parameters, print the degradable antibacterial hybrid material on the surface of the stent base on the 3D printing platform;

[0041] Step 5: After printing, a certain curing method is used to cure the biocompatible degradable coating layer containin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com