Controllable antibacterial towel containing silver-chelated acrylic fibers and making method of towel

A technology of acrylic fiber and silver chelation, which is applied in the direction of textiles and papermaking, household utensils, yarn, etc., can solve the problem that it is difficult to balance antibacterial performance, hand feel and durability, affect the comfort and hand feel of towels, and have poor antibacterial performance of antibacterial fibers, etc. Problems, to achieve long-lasting antibacterial effect, avoid damage, the effect of healthy antibacterial way

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

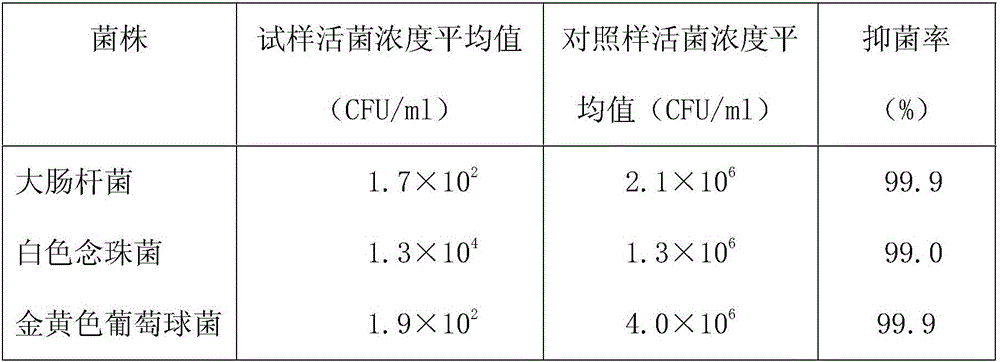

Embodiment 1

[0047] 0.5% by weight of silver-chelated acrylic fiber and 99.5% by weight of long-staple cotton fiber blended yarn, as loop yarn, consolidated on the base fabric with pure cotton yarn as the ground warp, to form towel gray cloth. Wherein, the silver content of the silver chelated acrylic fiber is 5% by weight.

[0048] A controllable antibacterial towel containing silver chelated acrylic fibers, the preparation steps of which are as follows:

[0049] (1) Preparation of blended yarn: pre-drawn commercially available silver chelated acrylic fibers are fed together with conventional commercially available fiber laps on the carding machine to make a carding raw material mixed with silver chelated acrylic fibers and conventional fibers. Further, use the mixed carding sliver of conventional fiber / silver chelated acrylic fiber and the carding sliver of conventional fiber to match in proportion on the drawing frame, make the silver chelated acrylic fiber in conventional fiber after t...

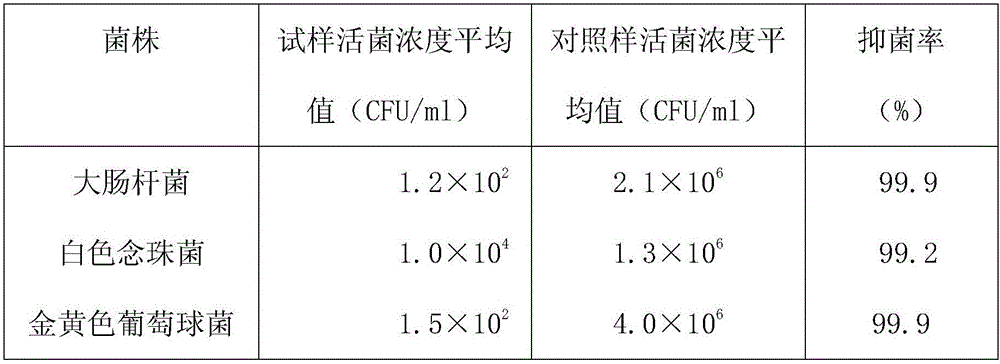

Embodiment 2

[0059] 1% by weight of silver-chelated acrylic fibers, 80% by weight of long-staple cotton fibers, and 19% by weight of hemp fiber blended yarns constitute loop yarns and ground yarns, which are prepared into towel gray fabrics. Wherein, the silver content of the silver chelated acrylic fiber is 10% by weight.

[0060] A controllable antibacterial towel containing silver chelated acrylic fibers, the preparation steps of which are as follows:

[0061] (1) Preparation of blended yarn: pre-drawn commercially available silver-chelated acrylic fibers are fed together with commercially available long-staple cotton conventional fiber laps on the carding machine to make silver-chelated acrylic fibers and long-staple cotton fibers Mixed carding sliver; further, use the mixed carding sliver and hemp fiber mixed cotton lap conventional fiber carding sliver to match in proportion on the drawing frame, after two or three drawing frames, the silver chelated acrylic fiber is Obtain fully un...

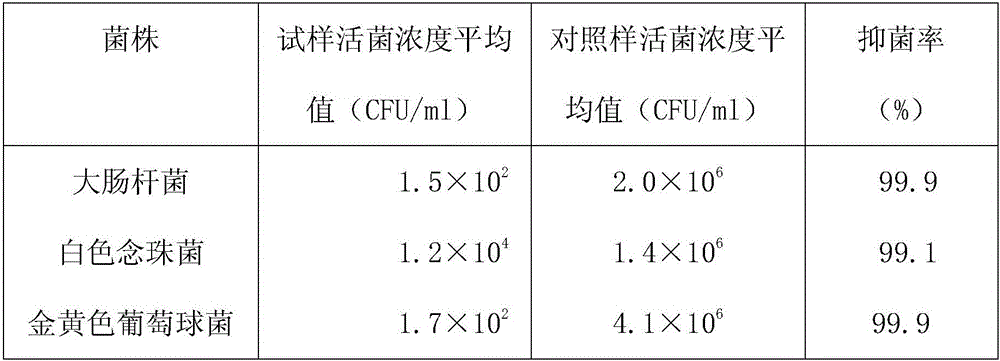

Embodiment 3

[0071] 1.5% by weight of silver-chelated acrylic fibers, 70% by weight of long-staple cotton fibers, and 28.5% by weight of polypropylene fiber blended yarns constitute loop yarns and ground yarns, which are prepared into towel gray fabrics. Wherein, the silver content of the silver chelated acrylic fiber is 15% by weight.

[0072] A controllable antibacterial towel containing silver chelated acrylic fibers, the preparation steps of which are as follows:

[0073](1) Preparation of blended yarn: pre-drawn commercially available silver chelated acrylic fibers are fed together with commercially available long-staple cotton fiber laps on the carding machine to make a silver chelated acrylic fiber / long-staple cotton fiber blend Carding sliver; further, the mixed carding sliver and polypropylene fiber carding sliver are matched in proportion on the drawing frame, and the silver chelated acrylic fiber is fully uniform in the conventional fiber after two or three drawing frames. Mix ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com