Titanium alloy compound-type quick disassembly and assembly automobile fuel tank protective plate

An automobile fuel tank, titanium alloy technology, applied in the direction of the deflector, power unit, vehicle parts, etc., can solve the problems of easy corrosion, structural failure, inability to achieve effective protection, etc., to achieve good heat dissipation and avoid corrosion.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

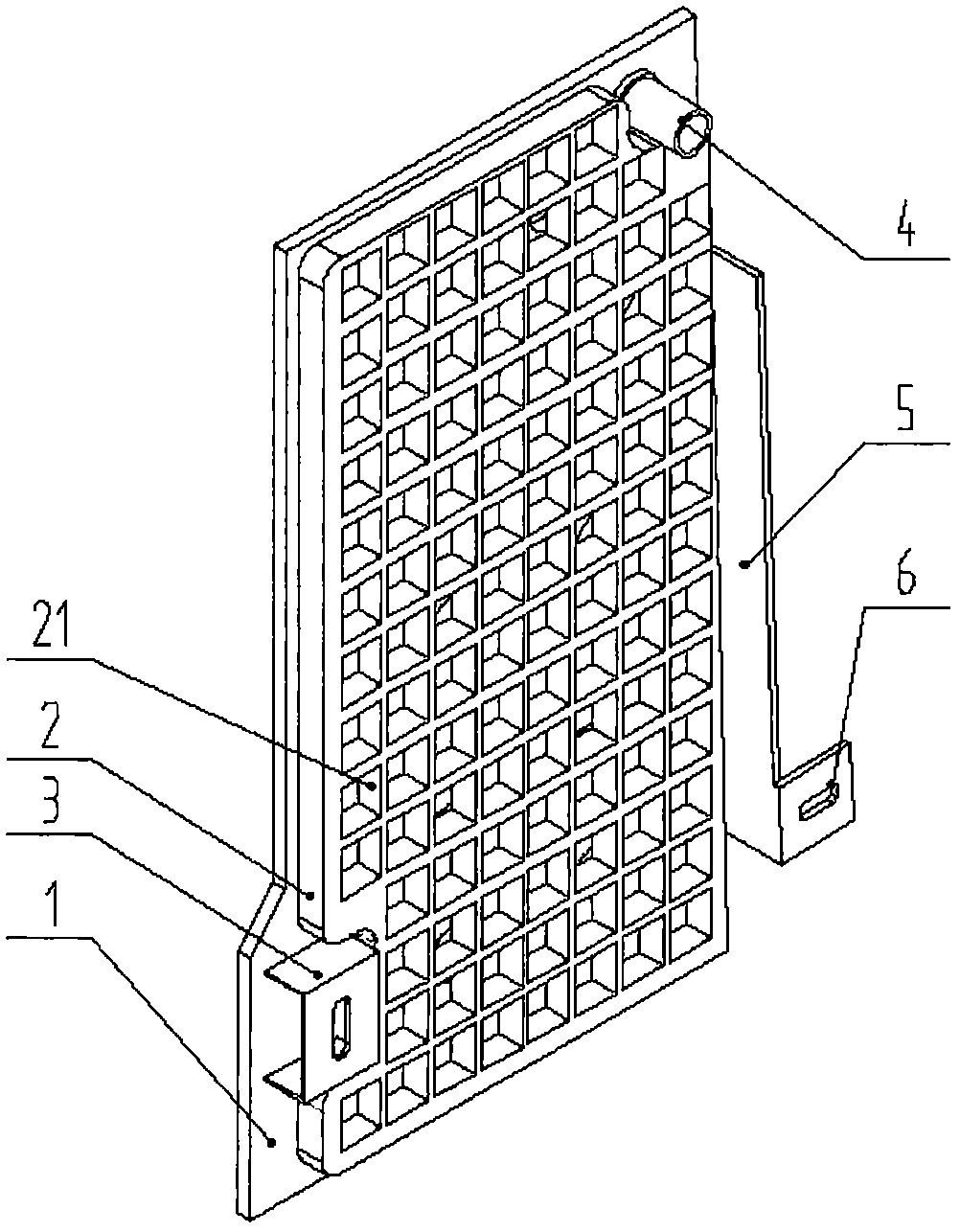

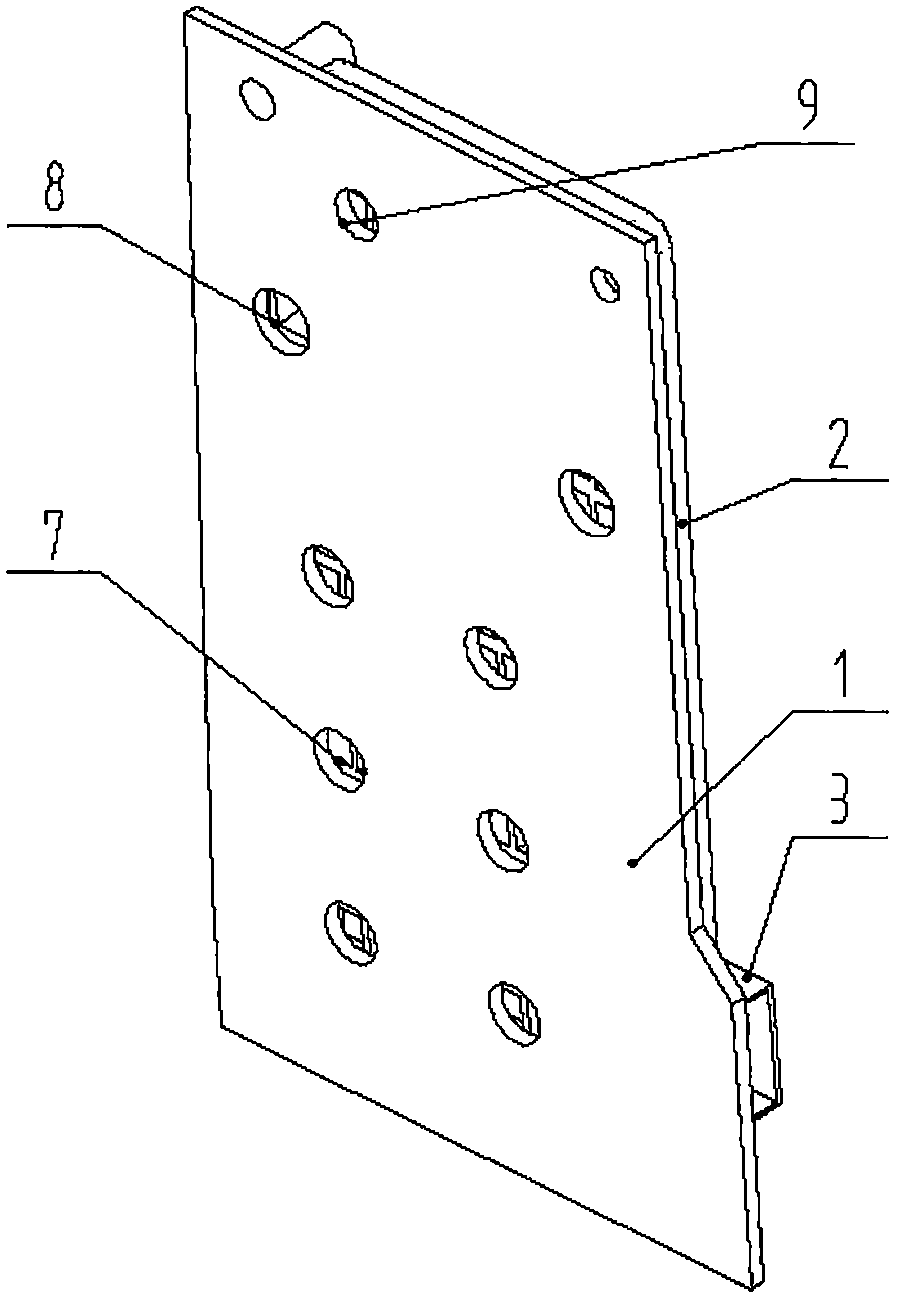

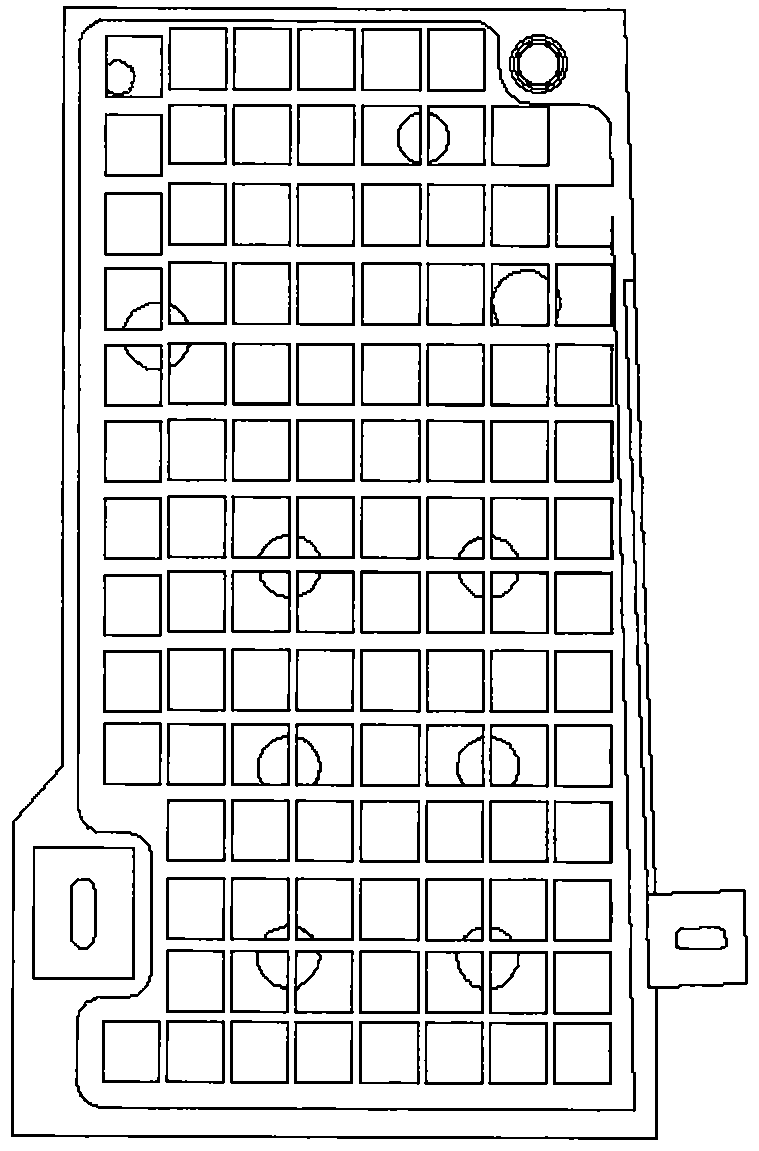

[0019] Attached below figure 1 , 2 and 3 further illustrate the present invention, as shown in the figure:

[0020] A titanium alloy composite type quick disassembly car fuel tank guard plate, comprising a rectangular metal guard layer 1 with a flange on one side, the metal guard layer 1 has a liner installation groove 3 on the flange, the There is a vertical installation edge 5 on the opposite side of the flange of the metal protection plate layer 1, and the end of the vertical installation edge 5 has an installation groove 6 parallel to the metal protection plate layer 1, and the opposite side of the flange of the metal protection plate layer 1 There is a sunken installation hole 4 on the corner, which is characterized in that: the inner installation surface of the metal shield layer 1 is covered with an inner lining protective layer 2, and the inner lining protective layer 2 and the inner lining installation groove 3 are sunken There is a counterbore at the corresponding ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com