Rotary disc type automatic stacking and loading and unloading device

An automatic stacking and turntable technology, which is applied in the stacking, transportation and packaging of objects, and the unstacking of objects, etc., can solve the problems of narrow range of suitable processing equipment, low accuracy of product counting, and difficulty in reducing labor costs. , to achieve the effect of saving manpower, facilitating placement and saving drive units

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

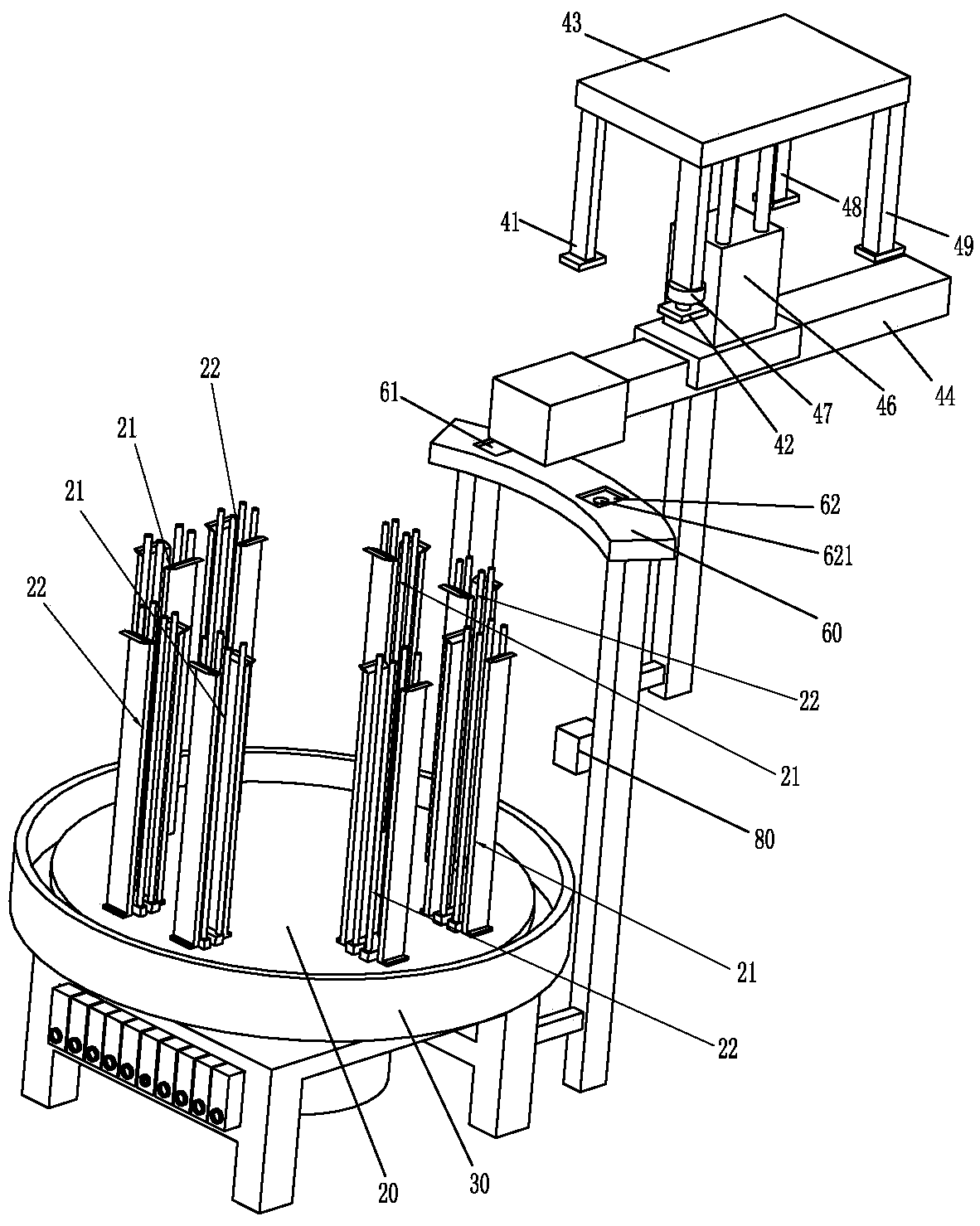

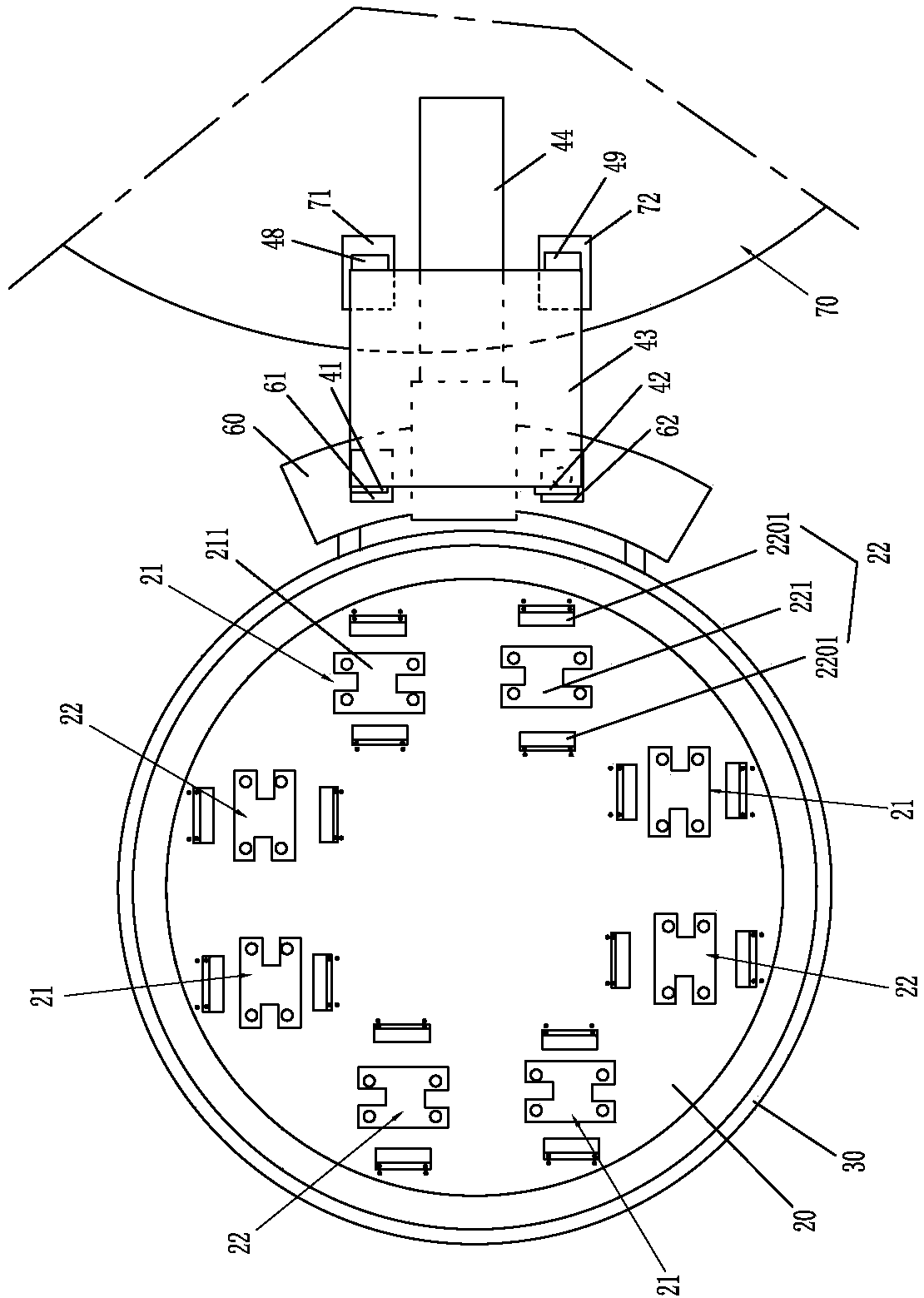

[0045] Please refer to Figure 1 to Figure 5 As shown, it shows the specific structure of the embodiment of the present invention.

[0046] A turntable-type automatic stacking and loading and unloading device, including a main control unit 10, a loading turntable 20 and an automatic transfer assembly; wherein:

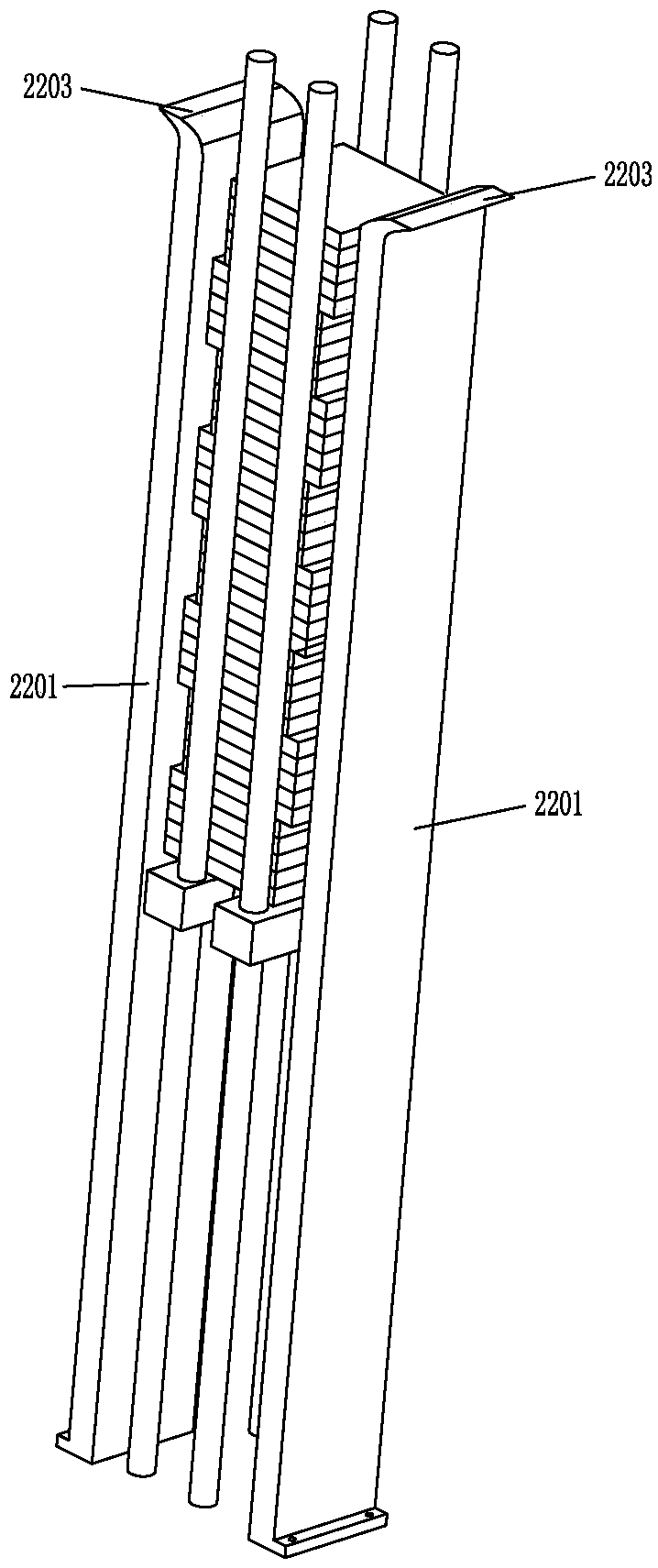

[0047]The loading turntable 20 is installed on the base frame 30, and the loading turntable 20 is connected with a turntable rotation drive unit 201 for driving the loading turntable 20 to rotate horizontally. Processed product placement rack 22; the product placement rack 21 has a product placement cavity to be processed and a material inlet connected to the upper end of the product placement cavity; the processed product placement rack 22 has a processed product placement cavity and is connected to the The feeding inlet at the upper end of the processed product placement cavity, the said product placement cavity to be processed and the processed product placement ca...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com