Metallic glass micron foil resistive strain sensor and preparation method thereof

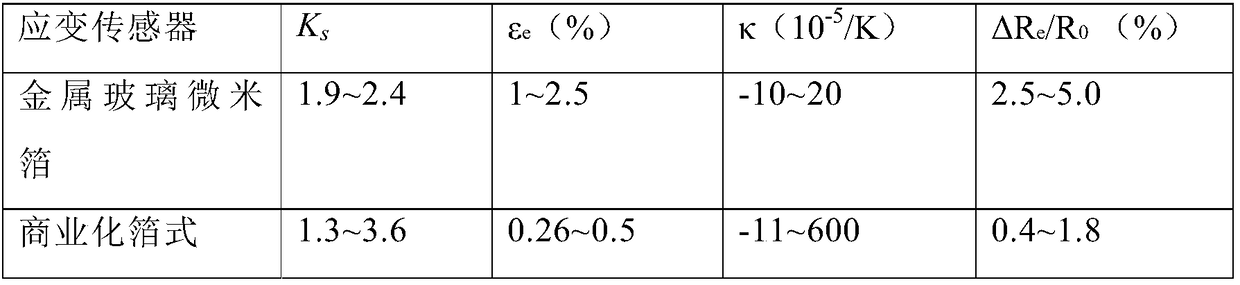

A technology of resistive strain and metallic glass, which is applied in the field of material science and sensors, can solve the problems of plastic deformation and strain gauges that cannot be reused, and achieve the effects of improved range and performance, convenient commercial promotion, and strong compatibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

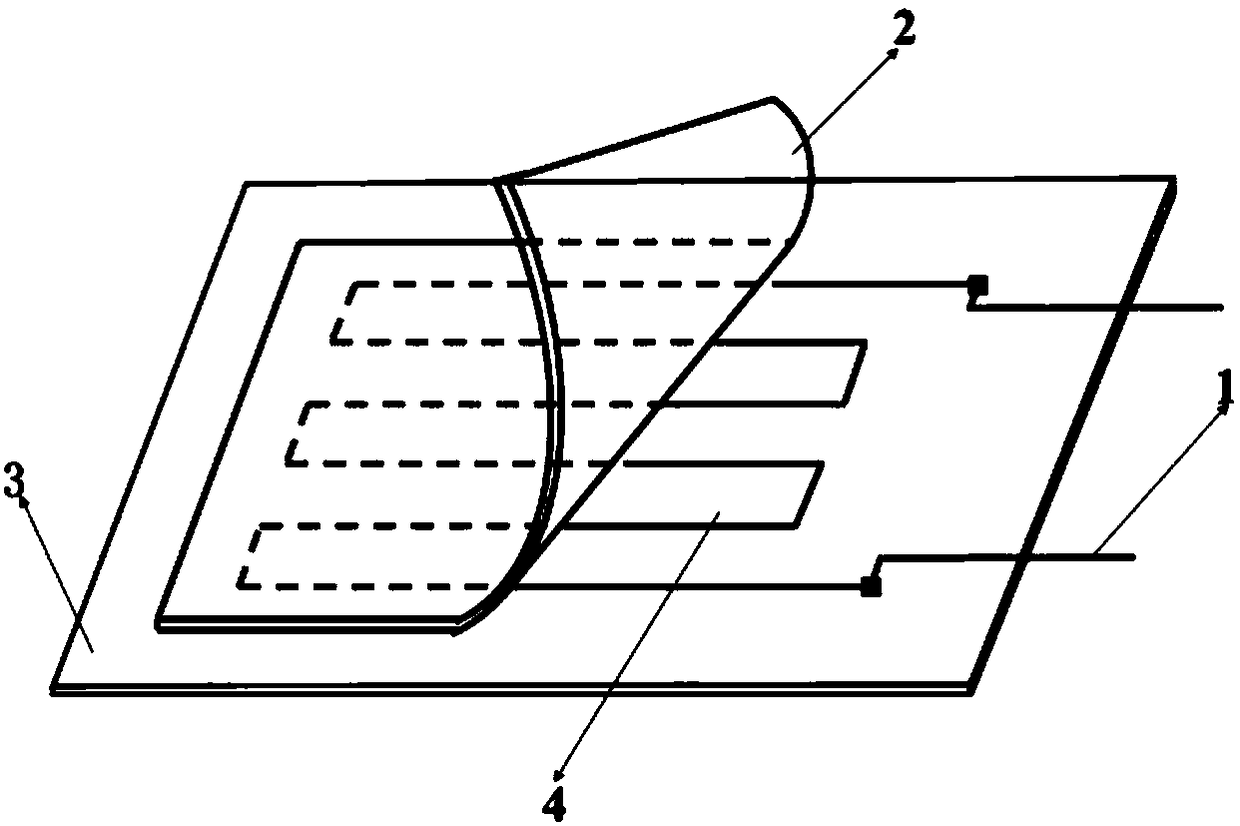

[0056] Embodiment 1: preparation Zr 60 Cu 25 Al 10 Fe 5 Metallic glass is a uniaxial strain gauge with a sensitive grid (that is, a resistive strain sensor).

[0057] This embodiment adopts Zr 60 Cu 25 Al 10 Fe 5 Metallic glass foil, the sensitive grid of the uniaxial strain gauge with a resistance value of 350Ω is prepared after photolithography, and the base material is epoxy phenolic film. The strain gauge can be used for various force measuring and weighing sensors.

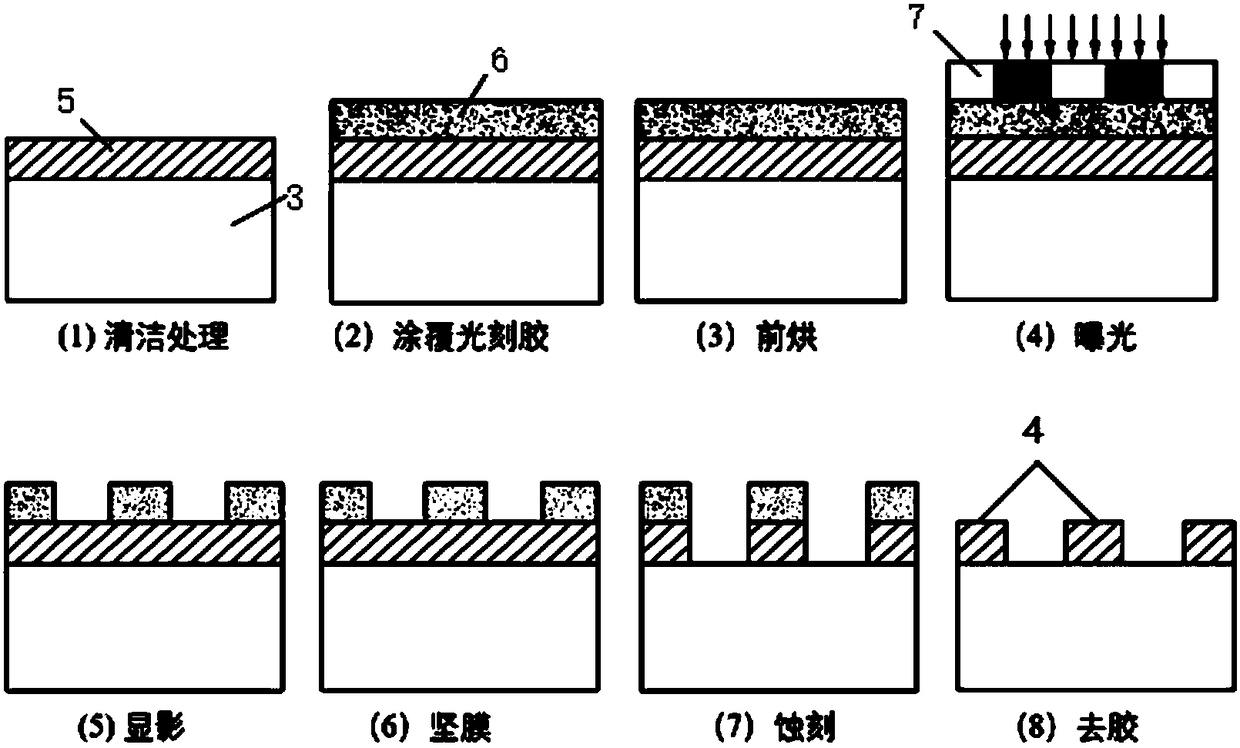

[0058] Specifically, the preparation steps of the uniaxial strain gauge are as follows:

[0059] 1. Preparation of film base

[0060] Zr with a thickness of 3 μm 60 Cu 25 Al 10 Fe 5 The metal glass foil 5 is fixed on a clean glass plate, and then the epoxy phenolic glue is dropped on the Zr 60 Cu 25 Al 10 Fe 5 The surface of the metal glass foil material 5 is sealed with an isolation cover, and after natural drying, the epoxy phenolic glue and the metal glass foil fixed on it are removed from ...

Embodiment 2

[0081] Example 2: Fe 31 co 31 Nb 8 B 30 Uniaxial shear strain gauge with metallic glass as sensitive grid

[0082] In this example, Fe 31 co 31 Nb 8 B 30 The metal glass foil is made of a sensitive grid of a uniaxial shear strain gauge with a resistance value of 350Ω after photolithography. The base material is made of epoxy phenolic film. The strain gauge can be used for shear sensors and torque sensors. Certainly, the base material may be any one of phenolic resin, epoxy resin, polyimide or glass fiber cloth, and is not limited to epoxy phenolic adhesive film.

[0083] Specifically, the preparation steps of the strain gauge are as follows:

[0084] 1. Preparation of film base

[0085] Fe with a thickness of 3 μm 31 co 31 Nb 8 B 30 The metal glass foil is fixed on a clean glass plate, and then the epoxy phenolic glue is dropped on the Fe with a straw. 31 co 31 Nb 8 B 30 Seal the surface of the metal glass foil with an isolation cover. After drying naturally, ...

Embodiment 3

[0105] Example 3: Zr 65 Al 10 Ni 10 Cu 5 Circular membrane strain gauge with metallic glass as sensitive grid

[0106] This embodiment adopts Zr 65 Al 10 Ni 10 Cu 5 Metallic glass foil, the sensitive grid of the circular membrane strain gauge with a resistance value of 350Ω is prepared after photolithography, and the base material is epoxy phenolic film. The strain gauge can be used as a pressure sensor for measuring fluid pressure.

[0107] Specifically, the preparation steps of the strain gauge are as follows:

[0108] 1. Preparation of film base

[0109] Zr with a thickness of 3 μm 65 Al 10 Ni 10 Cu 5 The metal glass foil is fixed on a clean glass plate, and then the epoxy phenolic glue is dropped on the Zr 65 Al 10 Ni 10 Cu 5 Seal the surface of the metal glass foil with an isolation cover. After drying naturally, remove the epoxy phenolic adhesive and the metal glass foil fixed on it from the glass plate, and then put it in an electric heating box for curi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com