Cement clinker production method

A cement clinker and production method technology, applied in the field of building materials, can solve the problems of production and quality decline, coal consumption, power consumption increase, affecting the quality and cost of cement clinker, etc., to improve flammability, reduce coal consumption, The effect of promoting the reaction rate of solid-state diffusion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

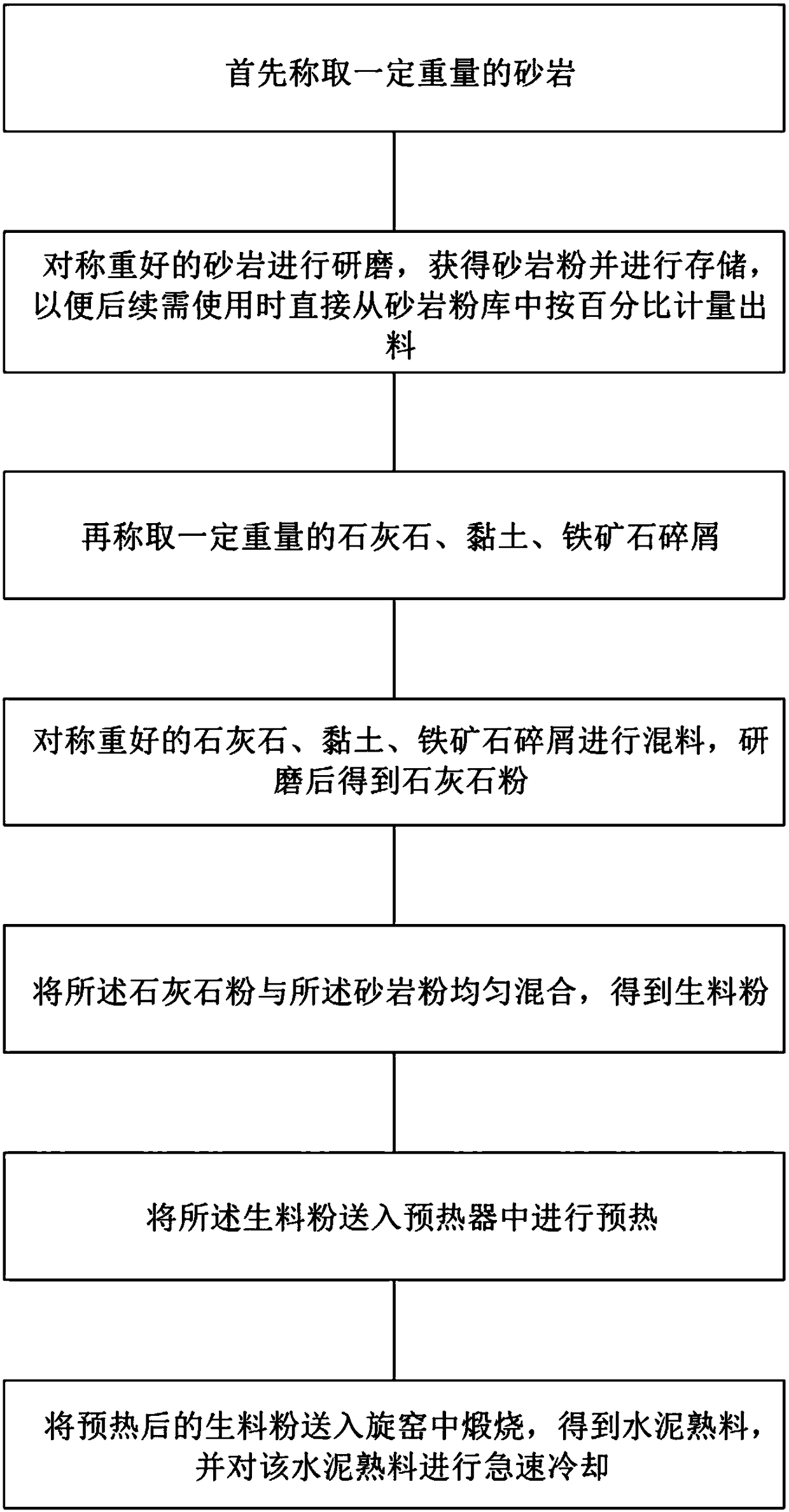

Image

Examples

Embodiment 1

[0042] A method for producing cement clinker, comprising:

[0043] Step 1, at first take the sandstone of certain weight;

[0044] Among them, the sandstone to be weighed is hard sandstone, its bond work index is not less than 15Kw.h / t, and the initial particle size of sandstone particles is less than 60mm.

[0045] Step 2: Grind the weighed sandstone to obtain sandstone powder and store it, and then directly measure and discharge the material from the sandstone powder warehouse according to the percentage when it needs to be used later;

[0046] Wherein, in this step, the weighed sandstone is ground, and the sandstone powder obtained after grinding is passed through a 75um sieve to ensure that 8-10% of the sieve remains, wherein, 8-10% refers to the fineness of the sandstone powder, and simultaneously The particle size of the quartz particles in the sandstone powder is less than 125 μm, and then the sandstone powder is stored, and the ground sandstone powder can be stored in...

Embodiment 2

[0058] A method for producing cement clinker, comprising:

[0059] Step 1, at first take the sandstone of certain weight;

[0060] Among them, the sandstone to be weighed is hard sandstone, its bond work index is not less than 15Kw.h / t, and the initial particle size of sandstone particles is less than 60mm.

[0061] Step 2: Grind the weighed sandstone to obtain sandstone powder and store it, and then directly measure and discharge the material from the sandstone powder warehouse according to the percentage when it needs to be used later;

[0062] Wherein, in this step, the weighed sandstone is ground, and the sandstone powder obtained after grinding is passed through a 75um sieve to ensure that 8-10% of the residue is sieved, wherein, 8-10% refers to the fineness of the sandstone powder, and simultaneously The particle size of the quartz particles in the sandstone powder is less than 125 μm, and then the sandstone powder is stored, and the ground sandstone powder can be store...

Embodiment 3

[0074] A method for producing cement clinker, comprising:

[0075] Step 1, at first take the sandstone of certain weight;

[0076] Among them, the sandstone to be weighed is hard sandstone, its bond work index is not less than 15Kw.h / t, and the initial particle size of sandstone particles is less than 60mm.

[0077] Step 2: Grind the weighed sandstone to obtain sandstone powder and store it, and then directly measure and discharge the material from the sandstone powder warehouse according to the percentage when it needs to be used later;

[0078] Wherein, in this step, the weighed sandstone is ground, and the sandstone powder obtained after grinding is passed through a 75um sieve to ensure that 8-10% of the residue is sieved, wherein, 8-10% refers to the fineness of the sandstone powder, and simultaneously The particle size of the quartz particles in the sandstone powder is less than 125 μm, and then the sandstone powder is stored, and the ground sandstone powder can be store...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com