Concrete repairing material

A repairing material and concrete technology, which is applied in the field of building materials, can solve the problems of time-consuming and labor-intensive surface treatment, unguaranteed quality, and inability to obtain adhesion, etc., and achieve the effect of preventing water vapor, preventing further damage, and good cement adaptability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

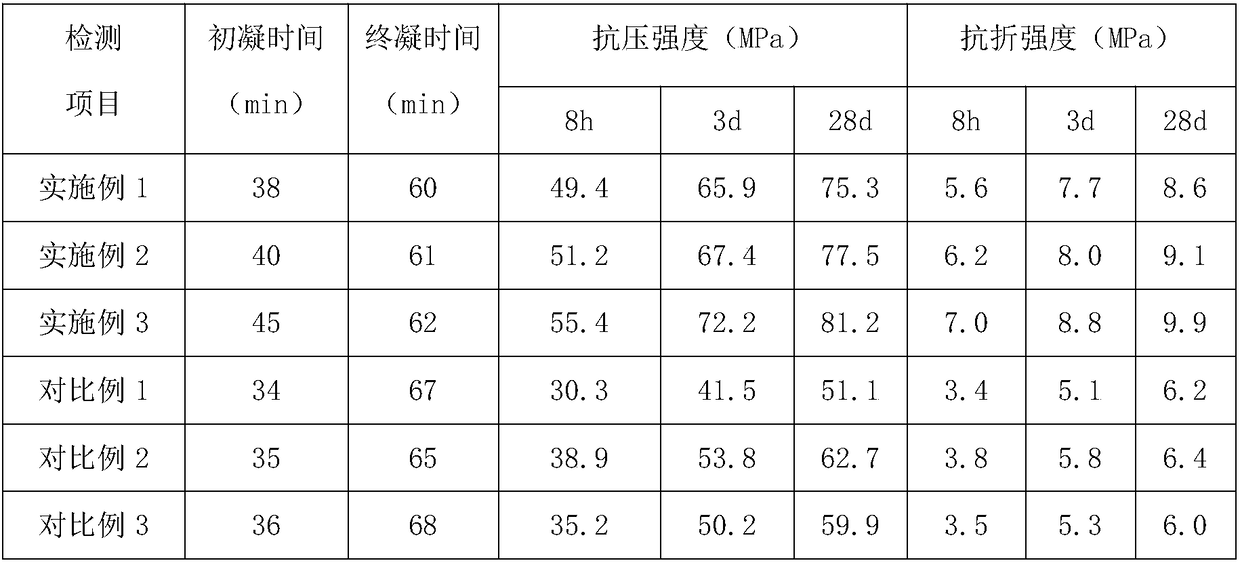

Examples

Embodiment 1

[0034]A concrete repair material, comprising the following components in mass percentage: 40% superfine cement, 4% silica fume, 45% redispersible latex powder, 6% huaqiansu, 24880.05% polyvinyl alcohol, hydroxyl Propyl methyl cellulose 0.2%, polyacrylamide 0.05%, ferrous ammonium sulfate 0.5%, tung oil 4%, methylphenyl cyclotrisiloxane 0.2%. Wherein, the viscosity of the hydroxypropyl methylcellulose is 120,000-180,000 mPa·s, the average particle size of the ultrafine cement is 0.2-0.3 μm, and the average particle size of the microsilica is 0.1-0.15 μm.

[0035] Preparation method: Weigh each raw material according to the above raw material formula, add various raw materials into the mixer in turn according to the formula amount at normal temperature and pressure, stir for 25-30 minutes, and mix evenly.

[0036] When the concrete repairing material of the present invention is applied to repairing cracks, the cracks should be washed away with clean tap water. Concrete repair m...

Embodiment 2

[0038] A concrete repair material, comprising the following components in mass percentage: 50% superfine cement, 2% silica fume, 40% redispersible latex powder, 4% huaqiansu, 24880.1% polyvinyl alcohol, hydroxyl Propyl methyl cellulose 0.4%, polyacrylamide 0.2%, ferrous ammonium sulfate 0.1%, tung oil 2.7%, methylphenyl cyclotrisiloxane 0.5%. Wherein, the viscosity of the hydroxypropyl methylcellulose is 120,000-180,000 mPa·s, the average particle size of the ultrafine cement is 0.2-0.3 μm, and the average particle size of the microsilica is 0.1-0.15 μm.

[0039] Preparation method: Weigh each raw material according to the above raw material formula, add various raw materials into the mixer in turn according to the formula amount at normal temperature and pressure, stir for 25-30 minutes, and mix evenly.

[0040] When the concrete repairing material of the present invention is applied to repairing cracks, the cracks should be washed away with clean tap water. Concrete repair ...

Embodiment 3

[0042] A concrete repair material, comprising the following components in mass percentage: 45% superfine cement, 4% silica fume, 43% redispersible latex powder, 5% Huaqiansu, 24880.1% polyvinyl alcohol, hydroxyl Propyl methyl cellulose 0.3%, polyacrylamide 0.1%, ferrous ammonium sulfate 0.2%, tung oil 2%, methylphenyl cyclotrisiloxane 0.3%. Wherein, the viscosity of the hydroxypropyl methylcellulose is 120,000-180,000 mPa·s, the average particle size of the ultrafine cement is 0.2-0.3 μm, and the average particle size of the microsilica is 0.1-0.15 μm.

[0043] Preparation method: Weigh each raw material according to the above raw material formula, add various raw materials into the mixer in turn according to the formula amount at normal temperature and pressure, stir for 25-30 minutes, and mix evenly.

[0044] When the concrete repairing material of the present invention is applied to repairing cracks, the cracks should be washed away with clean tap water. Concrete repair ma...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Viscosity | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com