Process method for producing high-purity chlorothalonil

A process method, the technology of chlorothalonil, is applied in the purification/separation of carboxylic acid nitrile, organic chemistry and other directions, which can solve the problems of complex operation process, unstable product quality, low degree of automation, etc., and achieve the effect of simple operation process.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

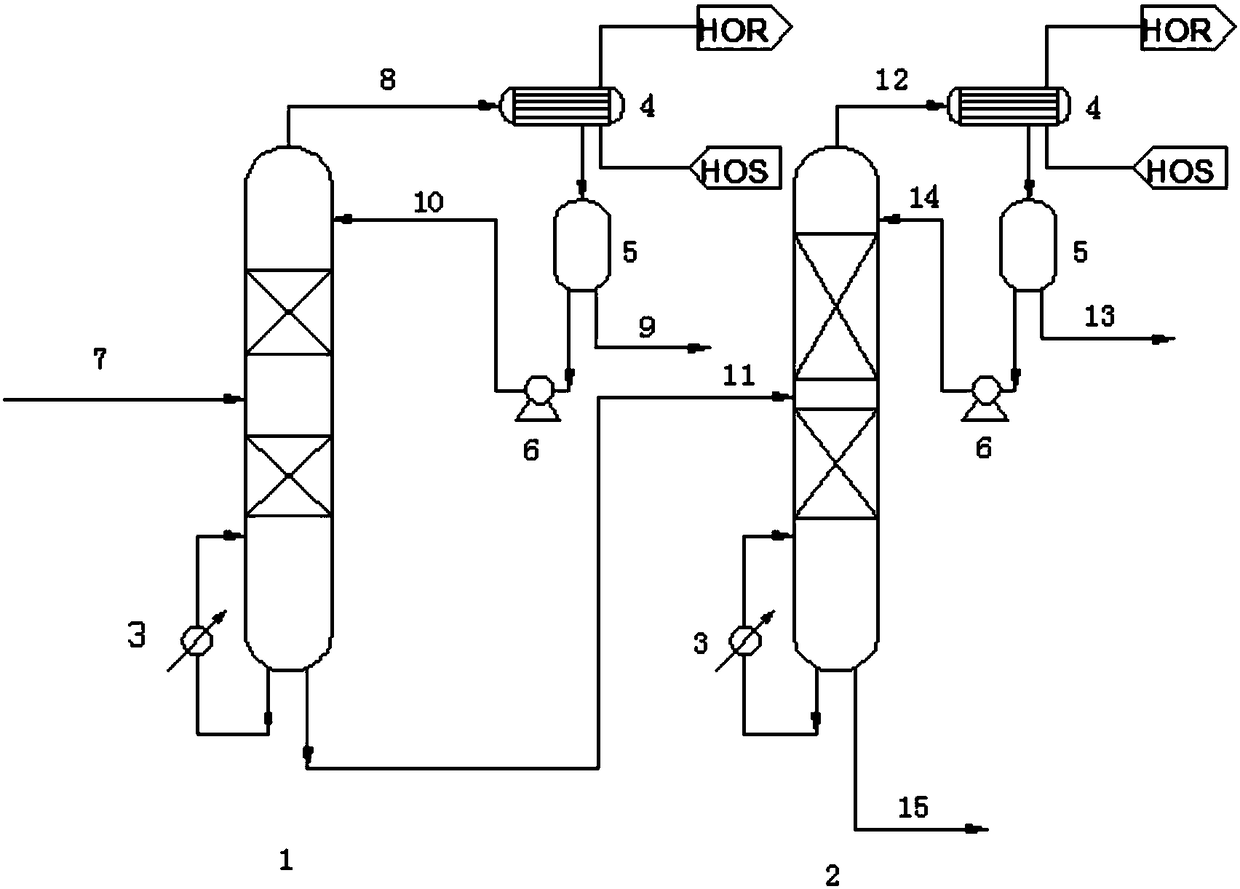

[0033] The mass fraction of chlorothalonil in the raw material 7 is 95.2%, and the raw material 7 containing chlorothalonil isophthalonitrile, trichloroisophthalonitrile, pentachlorobenzonitrile, hexachlorobenzene and water first enters the light removal tower 1 , the operating reflux ratio of the tower is 20:1, a light component mixture containing a small amount of chlorothalonil is extracted from the top of the tower, and the bottom of the tower is a material that does not substantially contain light components (the mass content of light components is 0.008%) , this material enters product tower 2, and this tower operating reflux ratio is 2:1, and this tower tower tower top extracts the qualified product chlorothalonil, and tower bottom extracts the heavy component that contains a small amount of product (the chlorothalonil product quality content is 16 %). The mass fraction of the product chlorothalonil is 99.8%, and the yield is 92.2%.

[0034] In this embodiment, both th...

Embodiment 2

[0037] The mass fraction of chlorothalonil in the raw material 7 is 95.5%, and the raw material 7 containing chlorothalonil isophthalonitrile, trichloroisophthalonitrile, pentachlorobenzonitrile, hexachlorobenzene and water first enters the light removal tower 1 , the operating reflux ratio of the tower is 22:1, a light component mixture containing a small amount of chlorothalonil is extracted from the top of the tower, and the bottom of the tower is a material that does not substantially contain light components (the light component mass content is 0.006%) , this material enters product tower 2, and this tower operation reflux ratio is 2.4:1, and this tower tower top extracts the qualified product chlorothalonil, and the heavy component that contains a small amount of product is extracted at the bottom of the tower (the mass content of chlorothalonil product is 15 %). The mass fraction of the product chlorothalonil is 99.7%, and the yield is 93.4%.

[0038] In this embodimen...

Embodiment 3

[0041] The mass fraction of chlorothalonil in the raw material 7 is 94.7%, and the raw material 7 containing chlorothalonil isophthalonitrile, trichloroisophthalonitrile, pentachlorobenzonitrile, hexachlorobenzene and water first enters the light removal tower 1 , the operating reflux ratio of the tower is 16:1, a light component mixture containing a small amount of chlorothalonil is extracted from the top of the tower, and the bottom of the tower is a material that does not substantially contain light components (the light component mass content is 0.008%) , this material enters product tower 2, and this tower operation reflux ratio is 1.7:1, and this tower tower top extracts the qualified product chlorothalonil, and the heavy component that contains a small amount of product is extracted at the bottom of the tower (the mass content of chlorothalonil product is 18 %). The mass fraction of the product chlorothalonil is 99.6%, and the yield is 92.8%.

[0042]In this embodiment...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com