Automatic point lofting robot and method

A robot and point-position technology, applied in the direction of instruments, non-electric variable control, two-dimensional position/channel control, etc., can solve the problems of point-point accuracy influence, time-consuming, low work efficiency, etc., and achieve high point-point accuracy, Short time consumption and overcoming the effect of low efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0061] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments, so that those skilled in the art can better understand the present invention and implement it, but the examples given are not intended to limit the present invention.

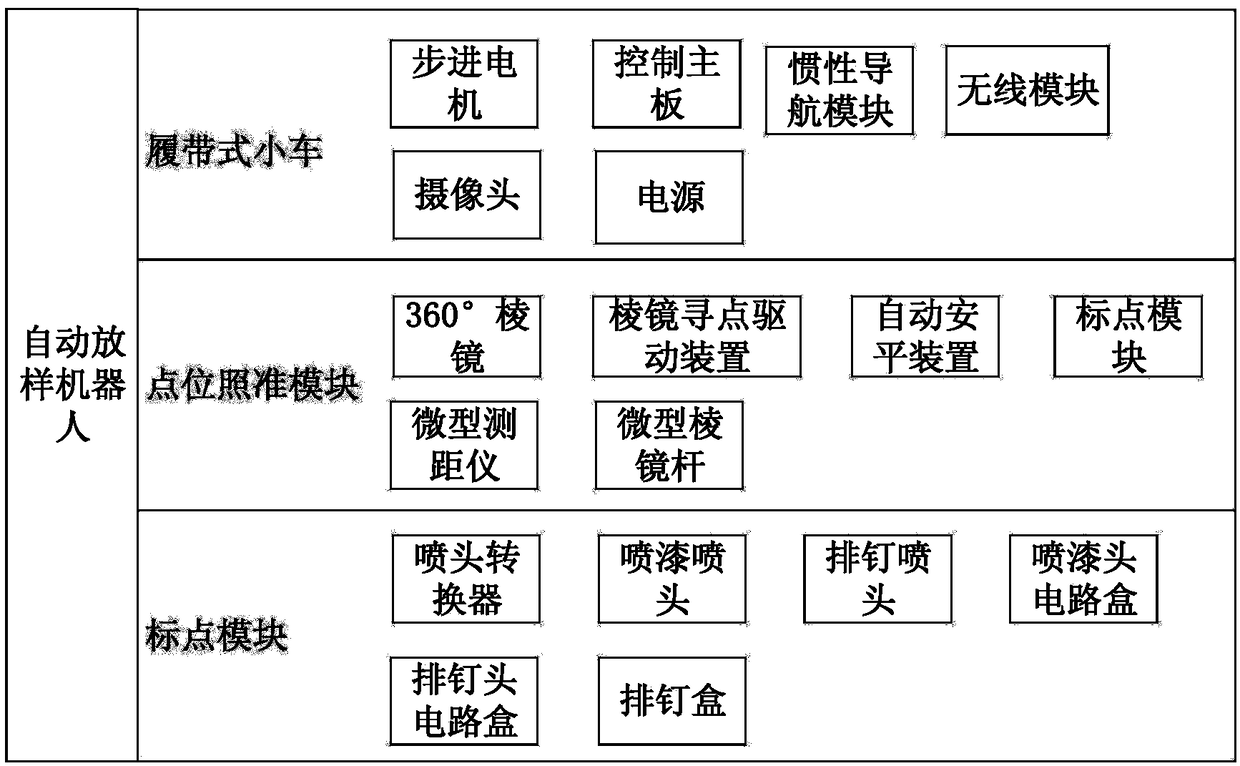

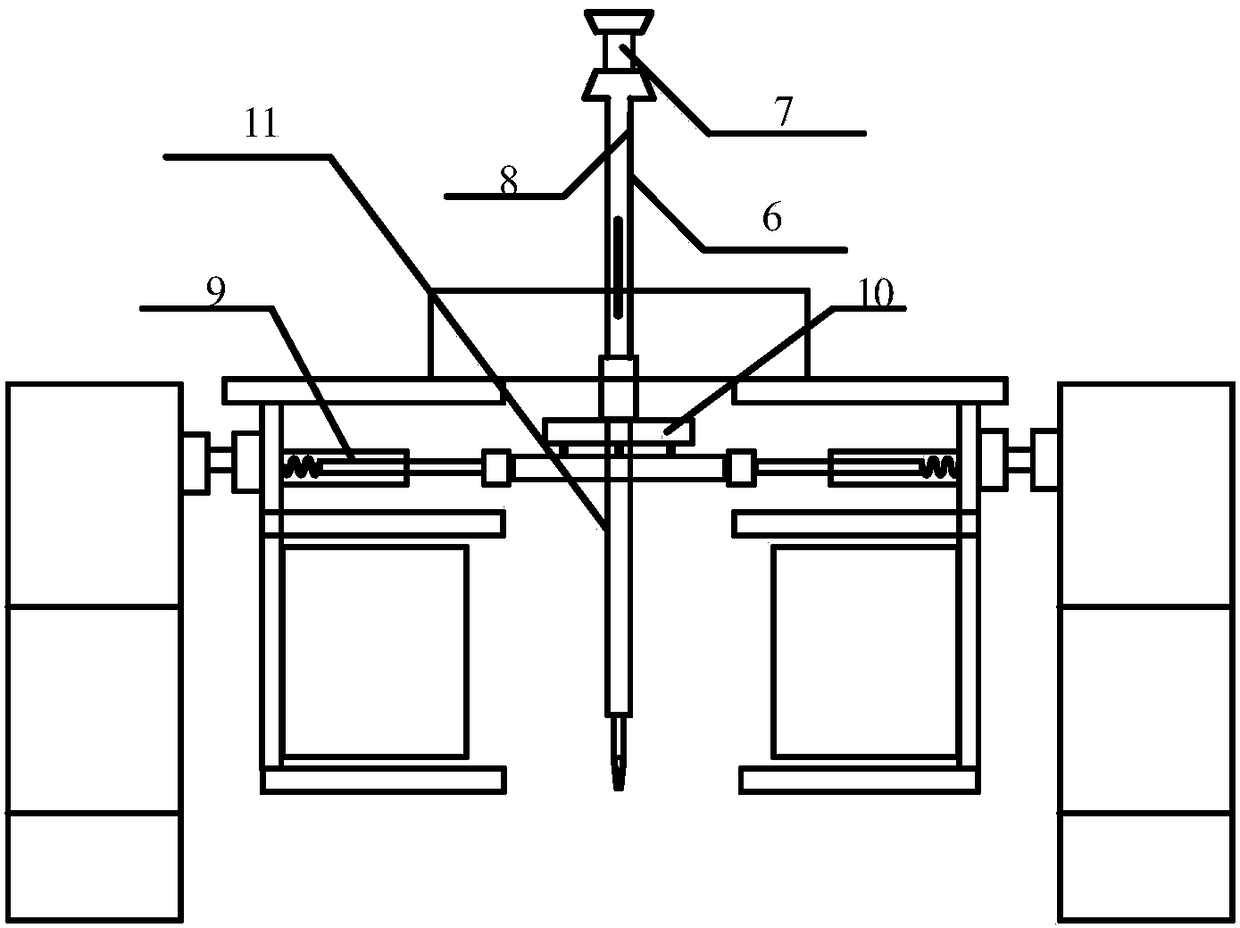

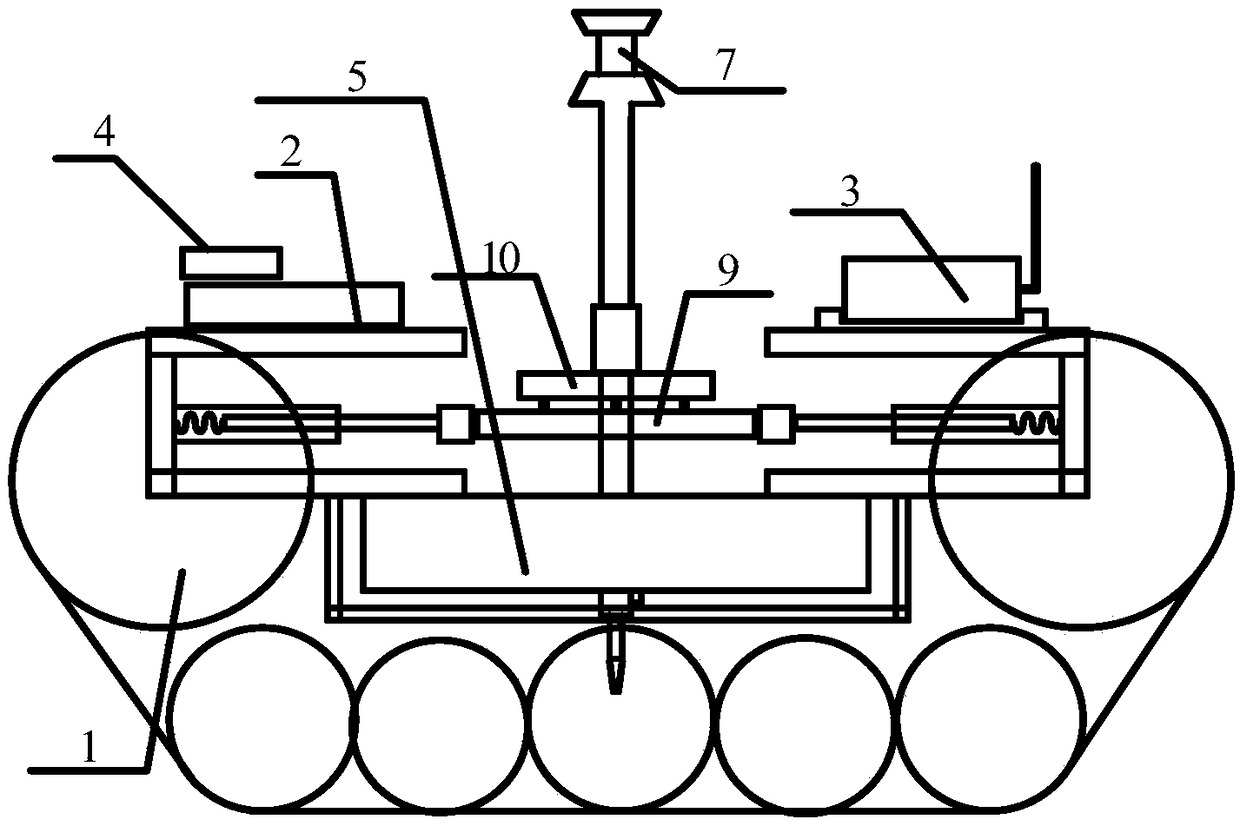

[0062] like figure 1 , figure 2 , image 3 As shown, they are the structural schematic diagram, the front view and the left view of an embodiment of the automatic point stakeout robot of the present invention, respectively. The automatic point stakeout robot includes: crawler trolley 1 (abbreviated as trolley 1), stepping motor ( figure 2 , image 3 Not shown in), control board 2, inertial navigation module ( figure 2 , image 3 Not shown in), wireless module 3, camera 4, power supply 5 and spot aiming module 6.

[0063] Among them, the stepping motor is set under the trolley 1 to provide driving power for the trolley 1; the control board 2 is set at the front above the t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com