Centering support for pressure bearing anchoring segment of pulling-pressing composite type anchor rod

A technology for centering brackets and anchoring sections, applied in sheet pile walls, buildings, infrastructure projects, etc., can solve the problems that the rod body deviates from the middle position of the borehole, affects the bearing capacity of the anchor rod, and is difficult to center construction, so as to ensure the protection of the project. safety, ensure the anchoring effect, and the effect of convenient construction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] In order to further explain the technical solution of the present invention, it will be described in detail below in conjunction with the accompanying drawings.

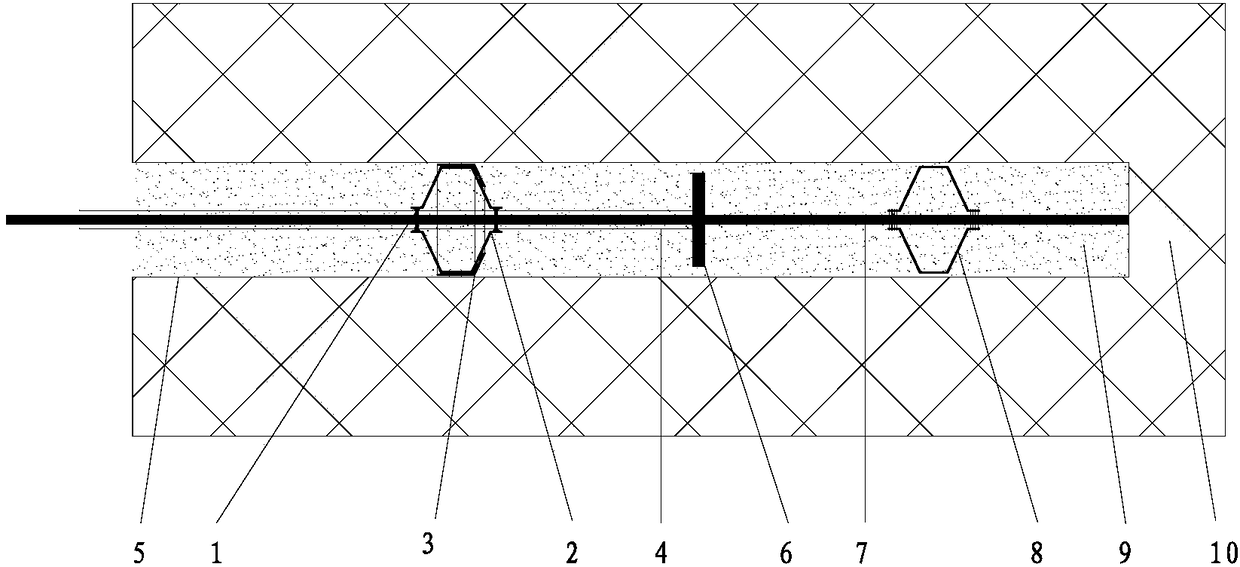

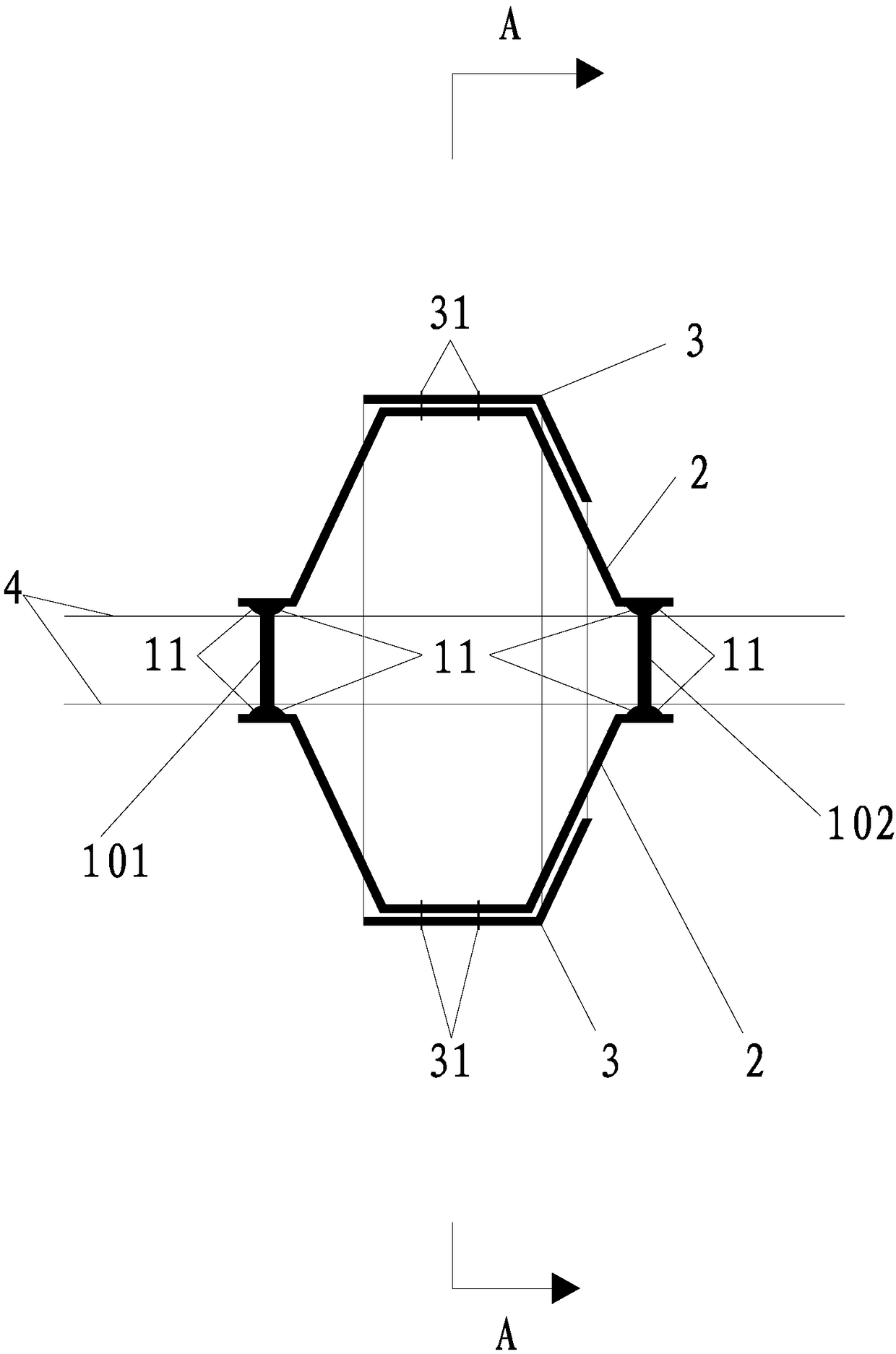

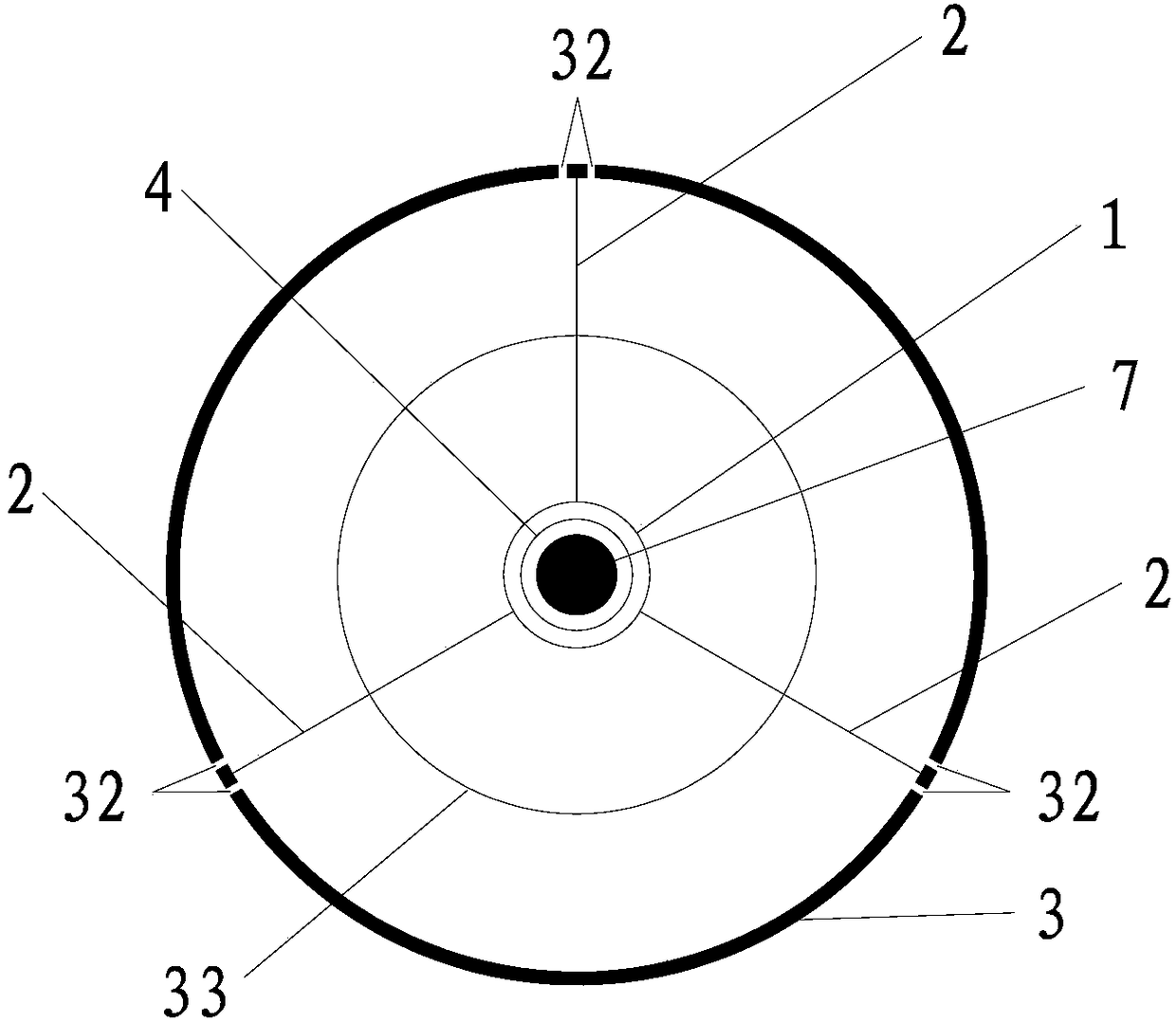

[0040] refer to Figure 1 to Figure 9 , a centering support for the pressure-bearing anchoring section of a tension-compression compound anchor rod, including a steel positioning ring 1, a steel support 2 and a plastic bracket 3.

[0041] The steel positioning ring 1 includes a first steel positioning ring 101 and a second steel positioning ring 102. Preferably, the steel positioning ring 1 is a smooth steel bar ring or a steel plate ring.

[0042] There are multiple steel brackets 2, and multiple steel brackets 2 rings are arranged outside the steel positioning ring 1. Each steel bracket 2 includes a first leg 21, a first waist 23, a back 25, and a second waist connected in sequence. 24 and the second support leg 22, the first support leg 21, the first support waist 23, the support back 25, the second suppor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com