Suction pile with suction device arranged at pile end

A technology of suction device and suction pile, which is applied in the field of suction pile, can solve the problems of complex pile foundation structure, small friction coefficient, high water content, etc., and achieve the effect of increasing the scope of application of the project, increasing the total bearing capacity, and good stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

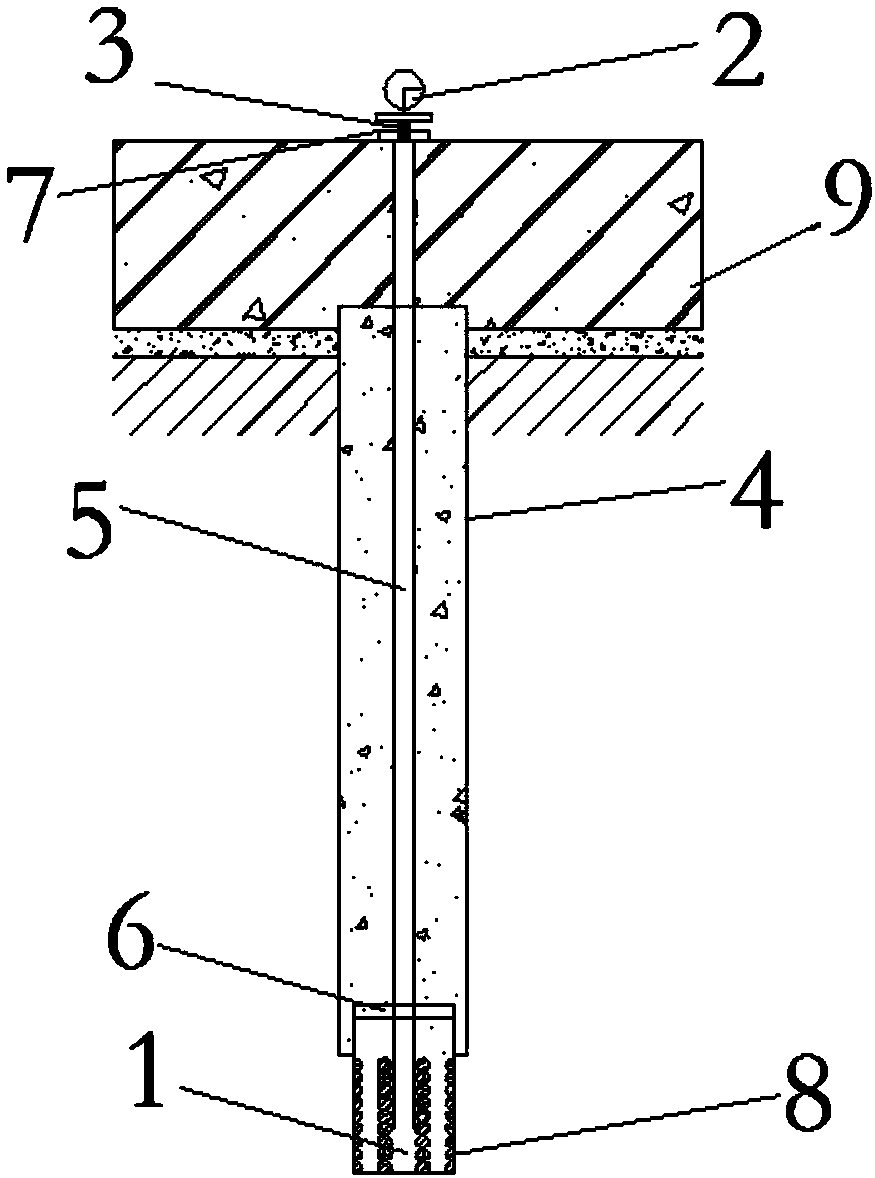

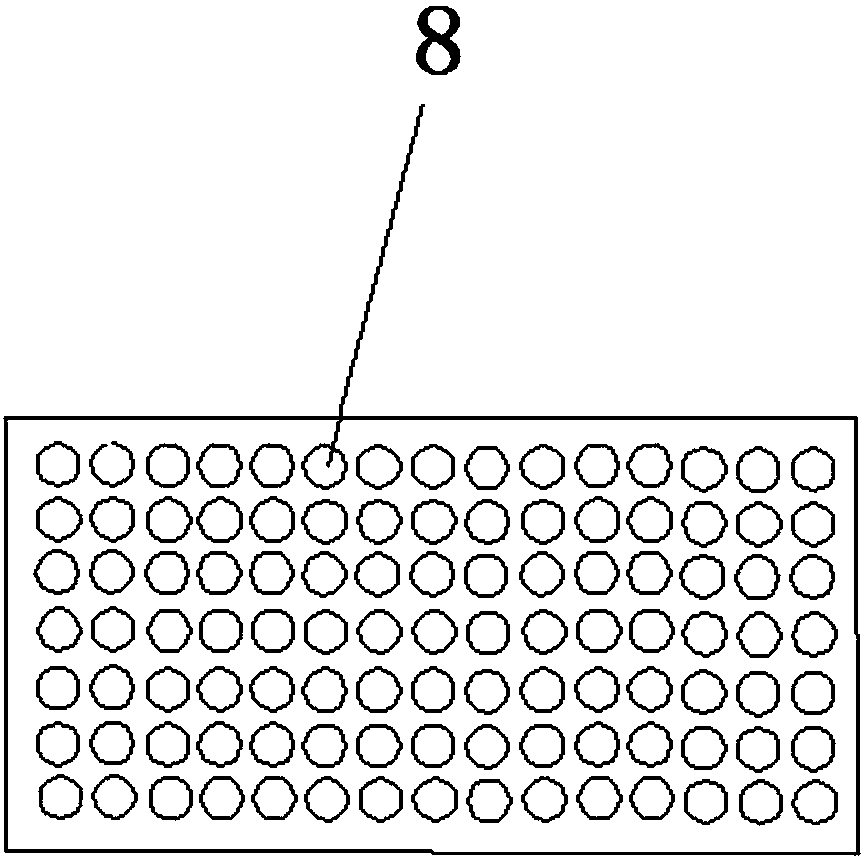

[0020] Referring to the accompanying drawings, a suction pile with a suction device at the pile end includes a columnar pile body 4, the top of the pile body 4 is located in the cap 9 and supports the cap 9 upwards, the bottom of the pile body 4 extends vertically downwards and Embedded in the soil body, and the bottom end of the pile body 4 is connected with a suction device 1 for improving the bearing capacity of the pile end soil (soil body at the end of the pile body 4); the top of the suction device 1 is airtightly embedded in the pile body 4 Inside and fixedly connected with the pile body 4, the bottom end of the suction device 1 extends downwards and exceeds the pile body 4; the suction device 4 is hollow cylindrical, and the top of the suction device 1 is fixedly arranged with 4 The sealing end surface 6 of the airtight partition, and a number of mesh holes 8 communicating with the inner cavity of the suction device 1 are evenly distributed on the side wall of the sucti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com