Novel thrust rod assembly

A thrust rod and assembly technology, which is applied to the cantilever mounted on the pivot, suspension, transportation and packaging, etc., can solve the problems of high energy consumption and easy breakage of the ball seat connection, so as to reduce the material cost and reduce The effect of the probability of fracture and detachment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

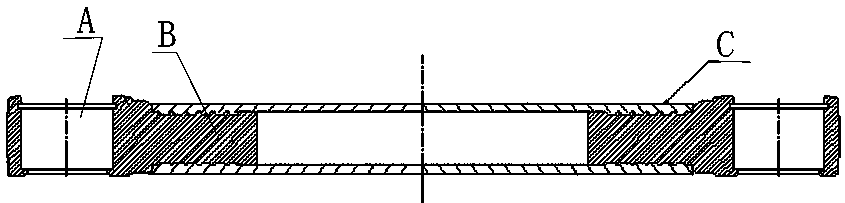

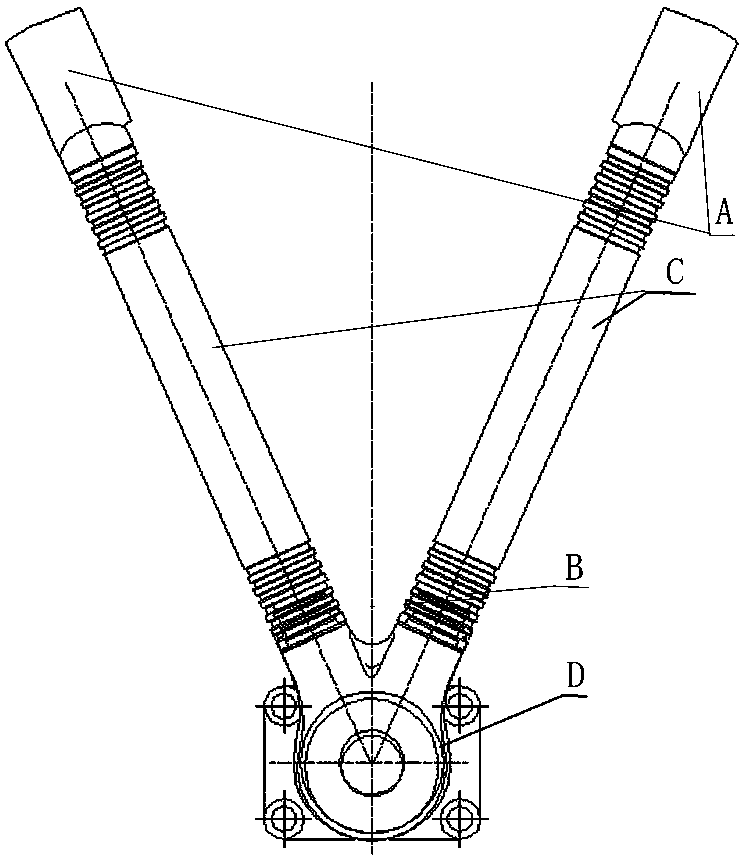

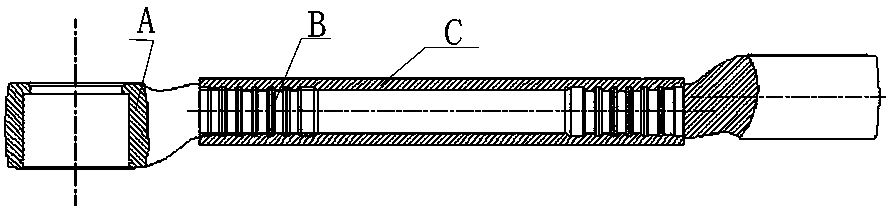

[0039] The invention as Figure 5 / 6 / 7 / 8 shown.

[0040] A new thrust rod assembly, including a first ball seat 1 and a second ball seat 2, the first ball seat 1 and the second ball seat 2 are cylindrical structures, the first ball seat 1 and the second ball seat 2 The seat 2 is connected by a connecting pipe 3, wherein the diameters of the two ends of the connecting pipe 4 gradually become larger, and the wall thickness gradually becomes thicker, so that it forms a concave arc surface matched with the outer surface of the cylindrical structure of the first ball seat 1 and the second ball seat 2 , and finally form a one-piece structure by welding.

[0041] The two ends of the connecting pipe 4 have a gradually larger diameter and a gradually thicker wall thickness, which is formed by upsetting.

[0042] The size ratio of the diameter of the two ends 4 of the connecting pipe to the middle diameter is 1.2-2:1.

[0043] The size ratio of the diameter of the two ends 4 of the c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com