Pipeline leakage location method based on cross-correlation

A pipeline leakage and location method technology, which is applied in pipeline systems, mechanical equipment, gas/liquid distribution and storage, etc., can solve problems such as difficulty in obtaining prior knowledge, low leak location accuracy, and inaccurate leak location , to achieve accurate pipeline leakage location, low requirements for relevant professional knowledge, simple and easy to achieve

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example

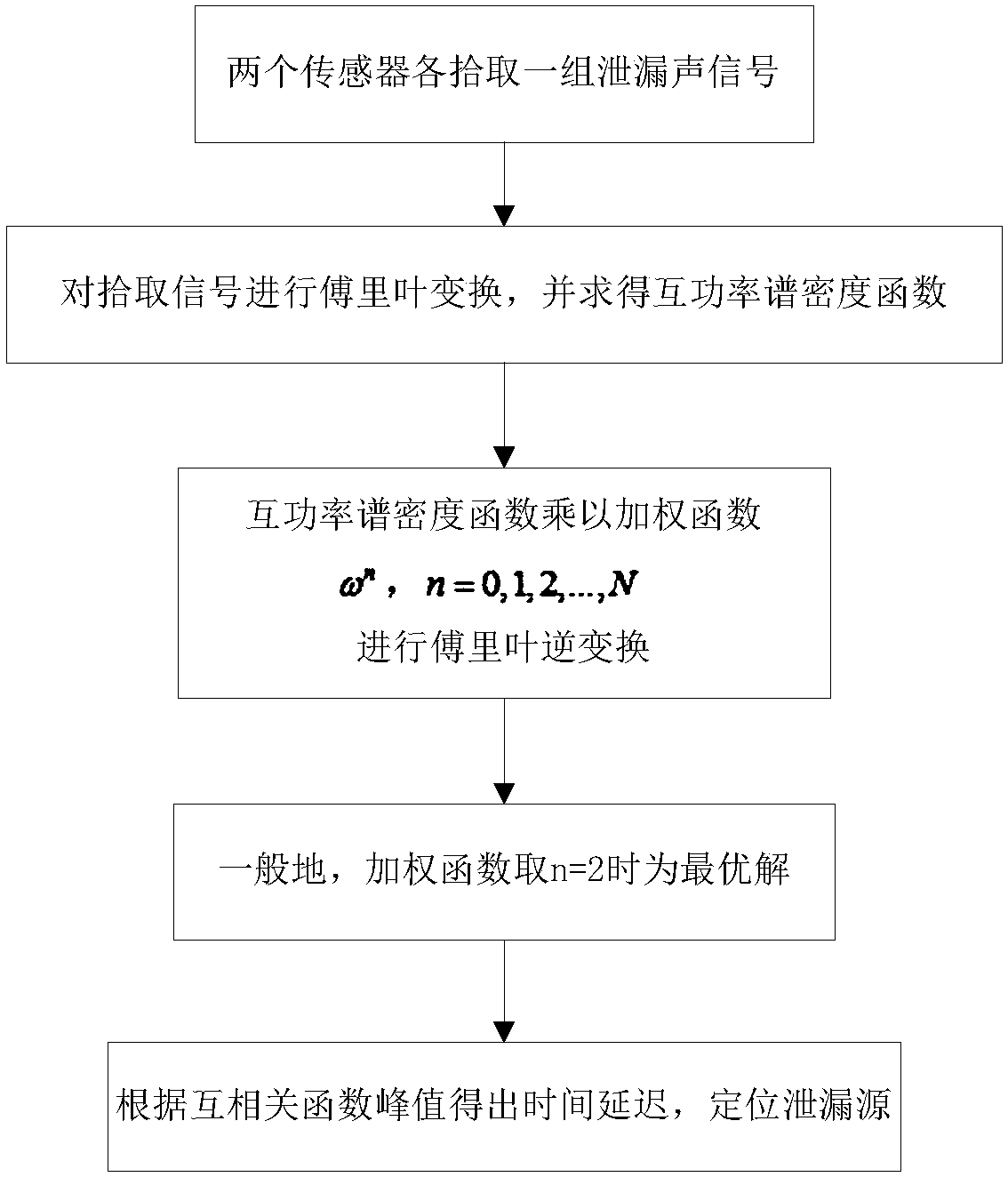

[0042] Step 1: When the underground water supply pipeline leaks, select two maintenance wells along the pipeline to be tested, and install a sensor at each end of the pipeline. The sensor type can be an acceleration sensor or a hydrophone. The sensor is connected to the data acquisition instrument, and two sets of time domain signals are collected synchronously.

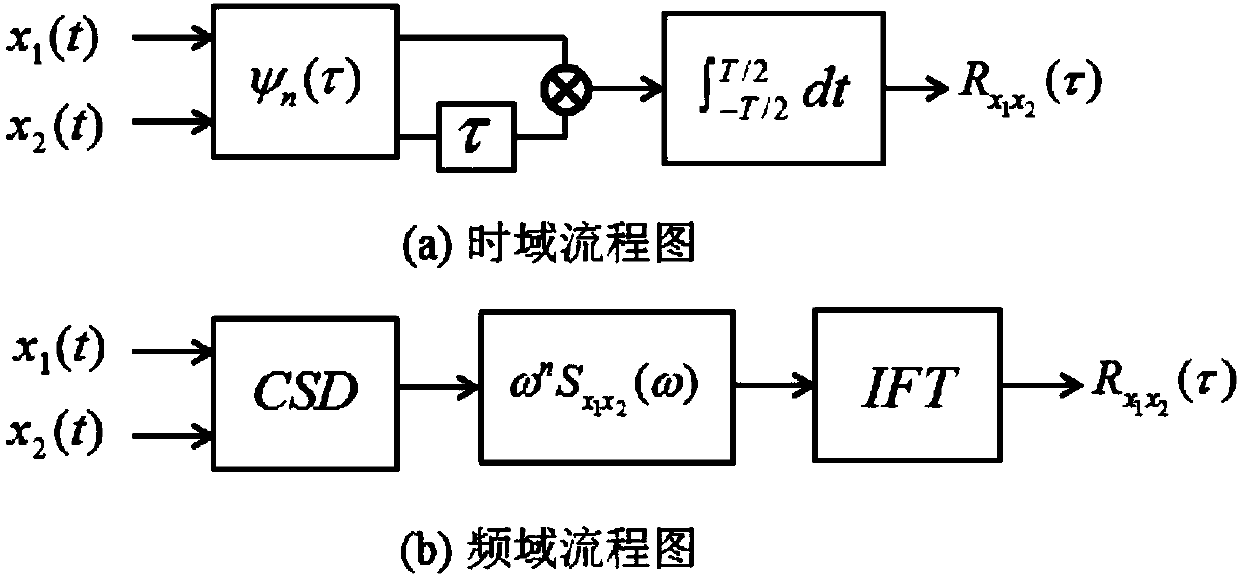

[0043] Step 2: Calculate the time-domain signal x picked up by the two sets of sensors k (t), (k=1,2) cross-power spectral density:

[0044]

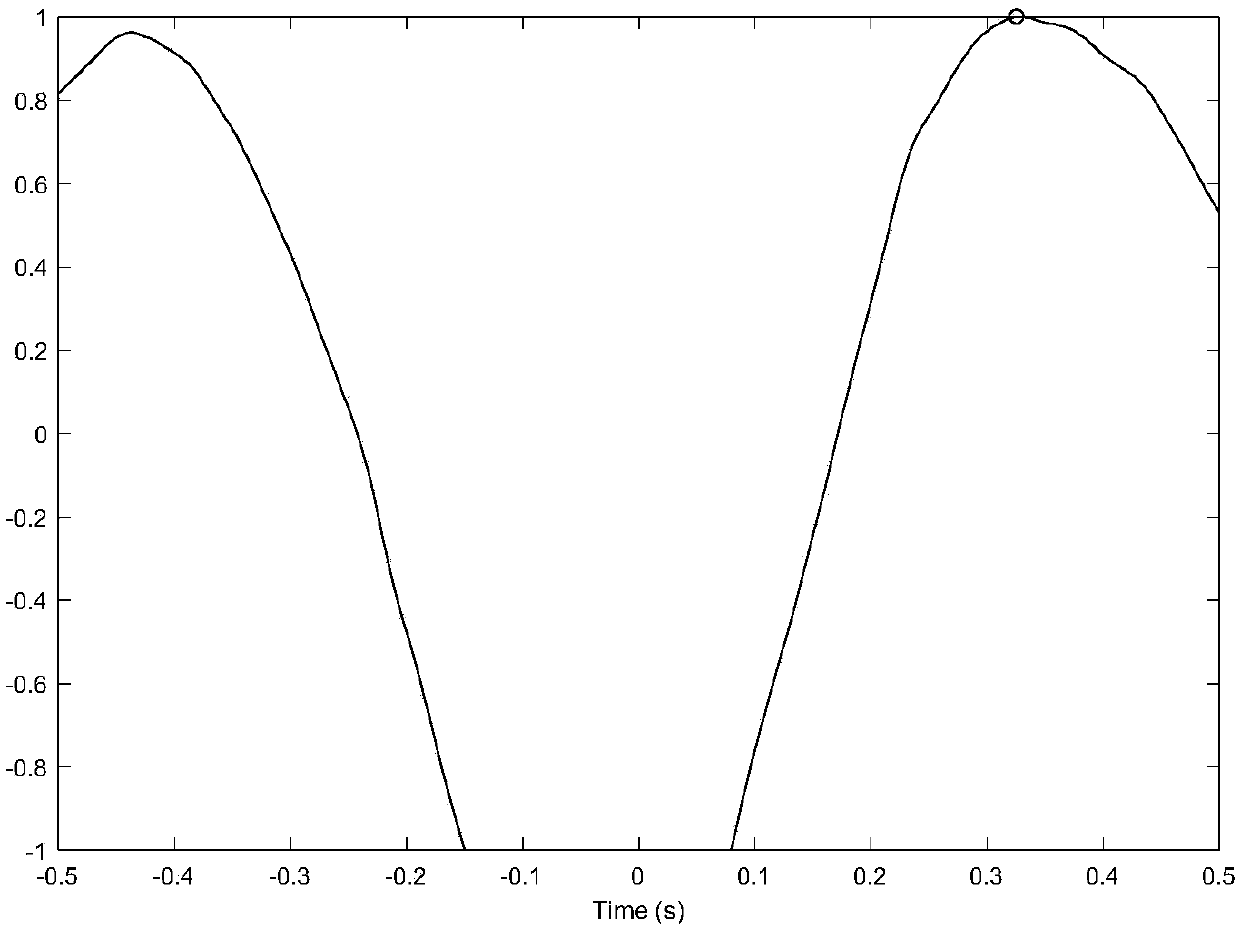

[0045] where * denotes complex conjugation. Weight the cross-power spectral density, where the weighting function is set to ω n (n=2), yes Multiplied by the frequency weighting function ω 2 After that, inverse Fourier transform is performed to obtain the cross-correlation function:

[0046]

[0047] Step 3: In the experiment, the actual time delay can be calculated by inversion of the positioning formula. The time delay formula can be expressed as:

[0048]

[00...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com