Method for determining adhesion between papermaking-reconstituted tobacco slices

A technology of tobacco sheet and measurement method, which is applied in the field of physical performance detection of tobacco sheet by papermaking method, and can solve problems such as lack of detection methods

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

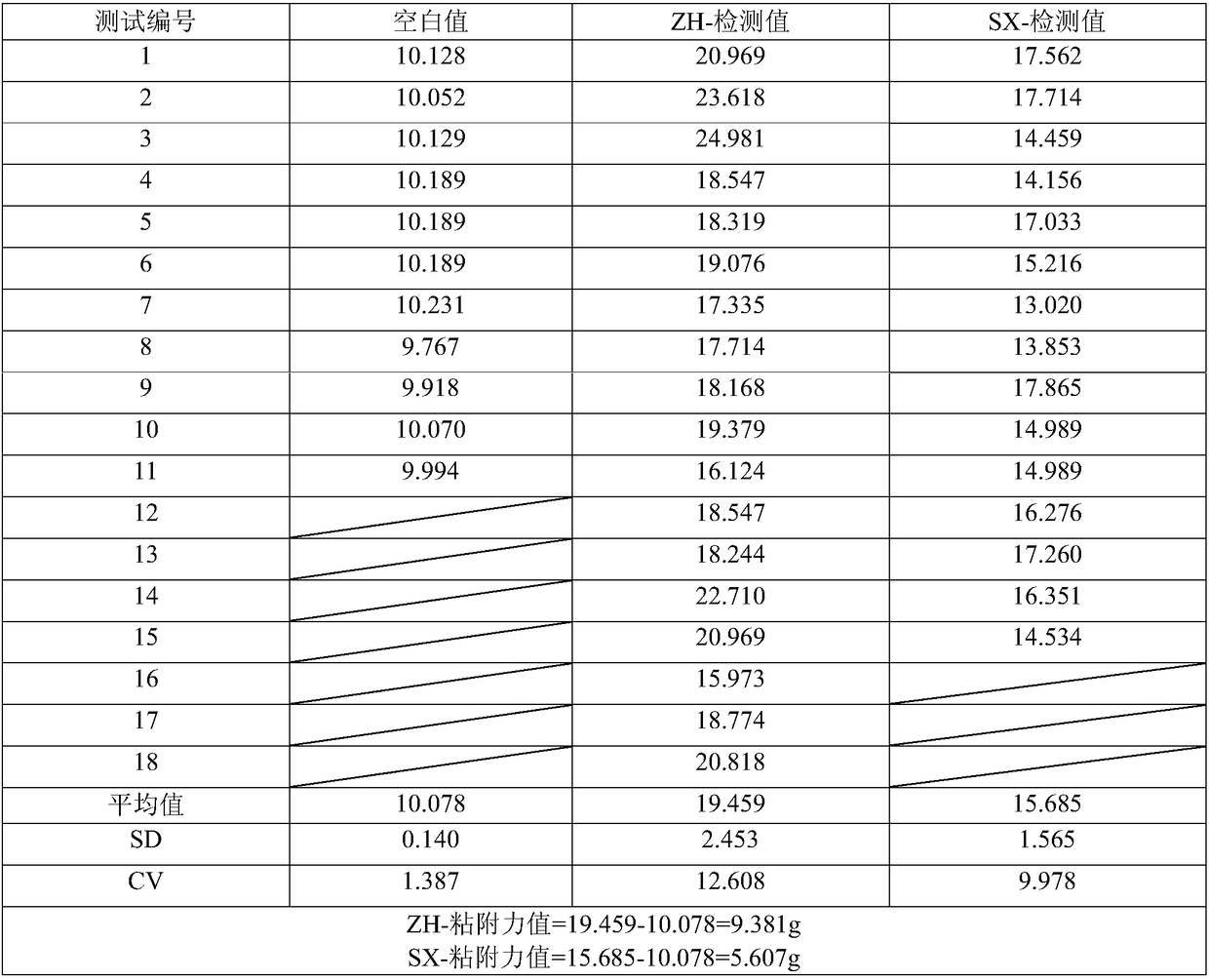

Embodiment 1

[0039] Choose tobacco flakes numbered ZH and SX tobacco flakes, the tobacco flakes have no obvious unfibrillated stems, no obvious sheet structure, and no obvious holes. The ZH tobacco sheet and the SX tobacco sheet are cut separately and placed in a constant temperature and humidity box with a temperature of 30° C. and a humidity of 85% for 24 hours to obtain the first sheet to be tested and the second sheet to be tested. Among them, the first slice to be tested after being cut is a circular slice, and its diameter is the same as the diameter of the bottom surface of the test probe; the second slice to be tested after being cut is a square slice with a side length larger than the first slice to be tested diameter of. The first sheet to be tested and the second sheet to be tested are quickly placed in a sealed container for testing.

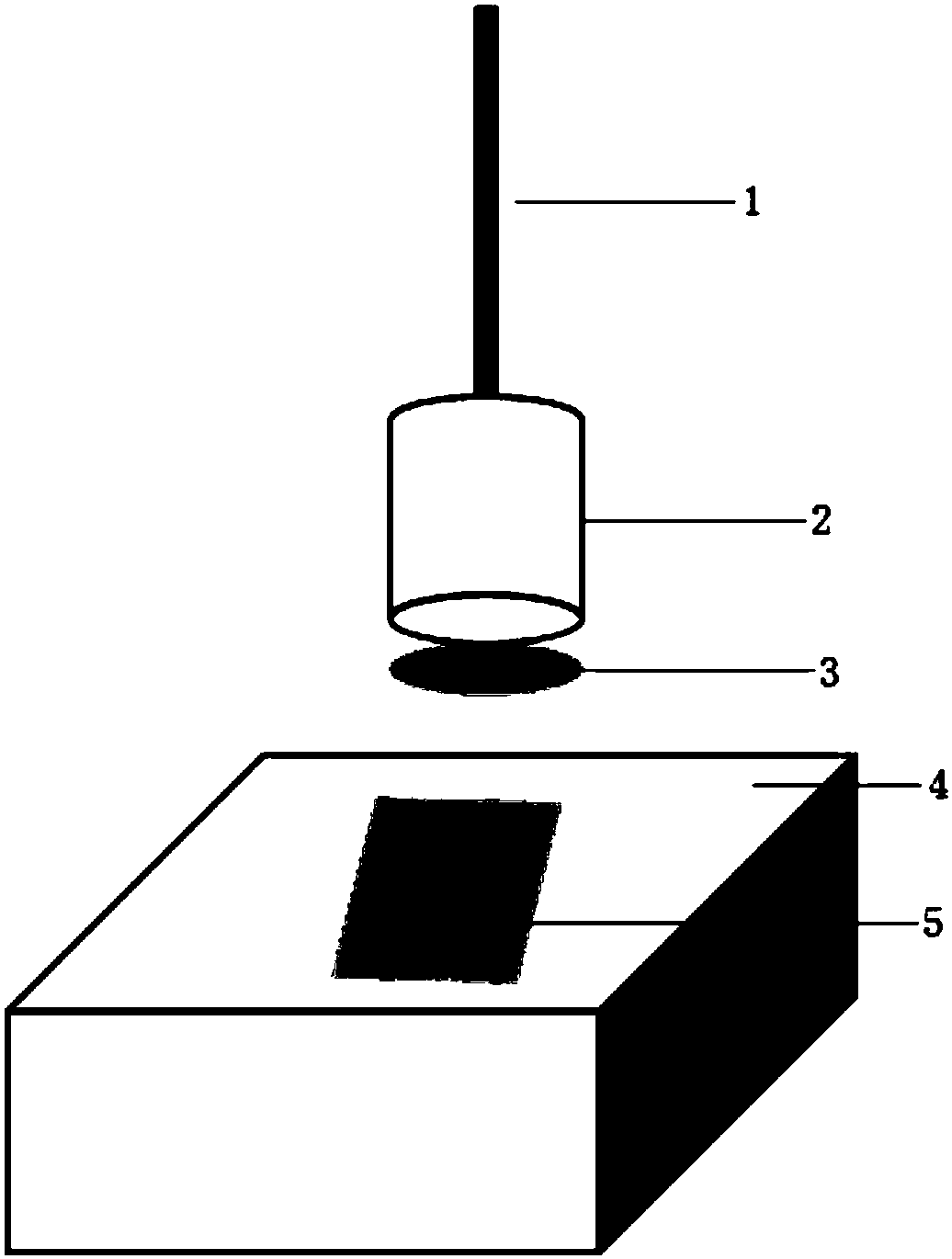

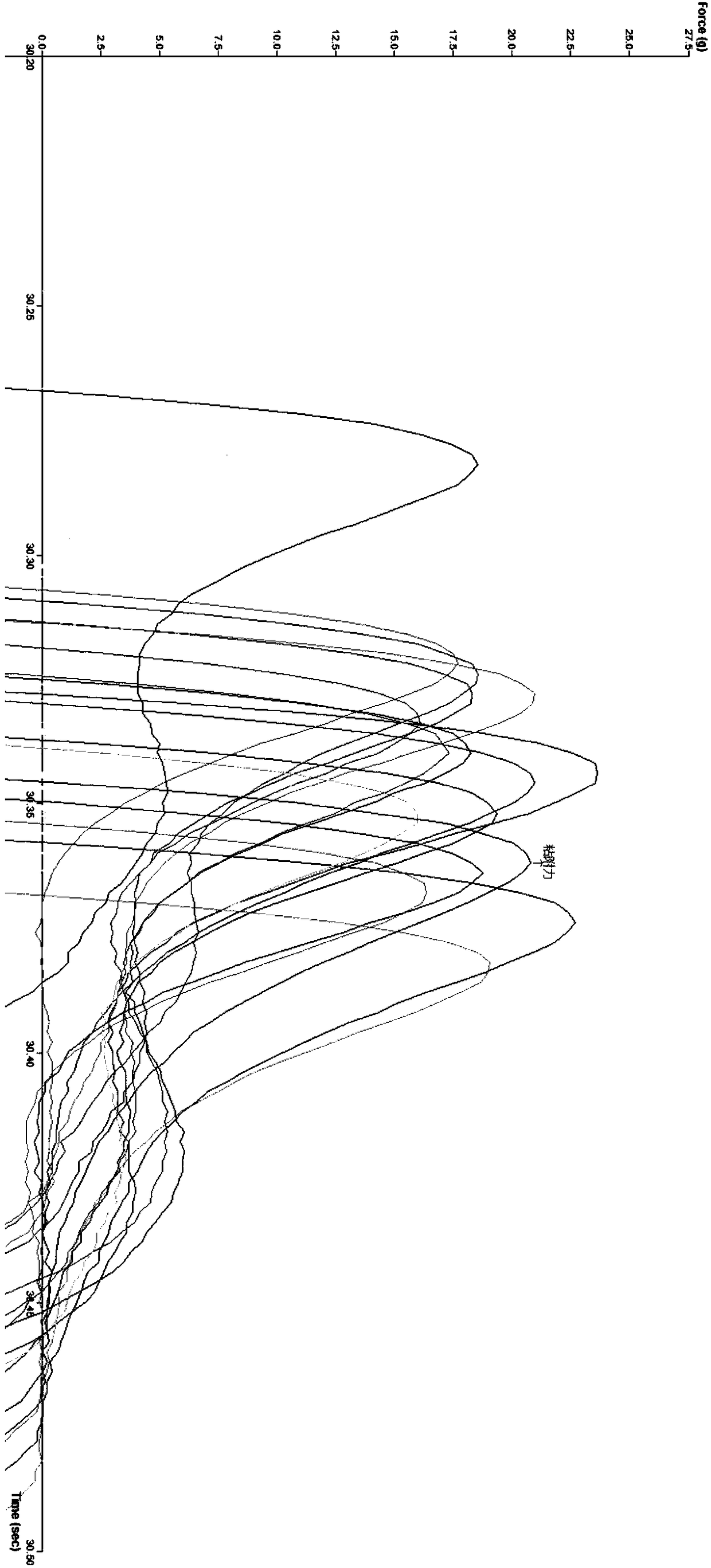

[0040] Select the test probe, the diameter of the bottom of the test probe is 30cm, and the bottom is smooth and free of debris. The test probe i...

Embodiment 2

[0047] Choose the tobacco sheet numbered MD. The tobacco sheet has no obvious unfibrillated stems, no obvious sheet structure, and no obvious holes. After cutting the MD tobacco sheet, it is placed in a constant temperature and humidity box with a temperature of 30° C. and a humidity of 85% for 24 hours to obtain a first sheet to be tested and a second sheet to be tested. Wherein, the first slice to be tested after cutting is a circular slice, the diameter of which is the same as the diameter of the bottom surface of the test probe; the second slice to be tested after cutting is a square slice, the side length of which is larger than that of the first slice to be tested diameter of. The first sheet to be tested and the second sheet to be tested are quickly placed in a sealed container for testing.

[0048] Select the test probe, the bottom diameter of the test probe is 30cm, and the bottom surface is smooth and free of debris. Install the test probe on the test platform of the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com