Deep learning-based smoke fire-prevention monitoring method of rail-train equipment room

A technology of rail trains and deep learning, applied in the fields of instruments, biological neural network models, character and pattern recognition, etc., can solve the problems of difficult detection of sensors, lack of accuracy and sensitivity of monitoring results, and insufficient data analysis. Comprehensive, good fault tolerance, high accuracy effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

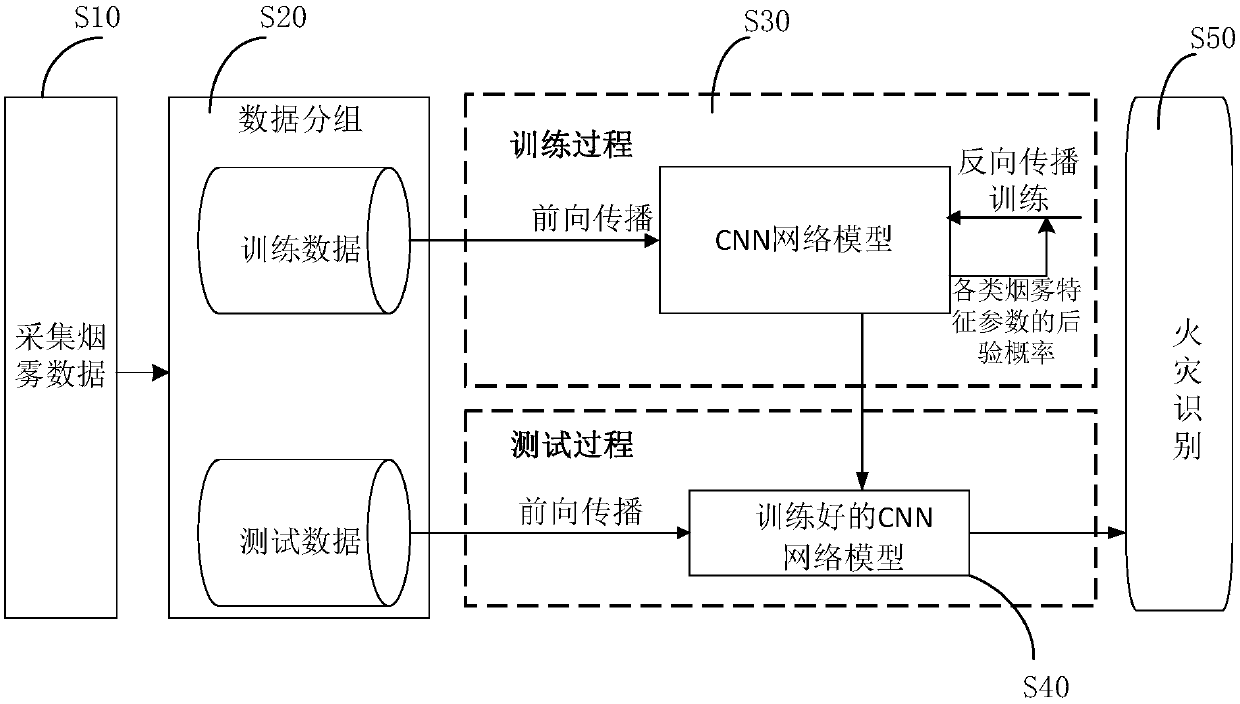

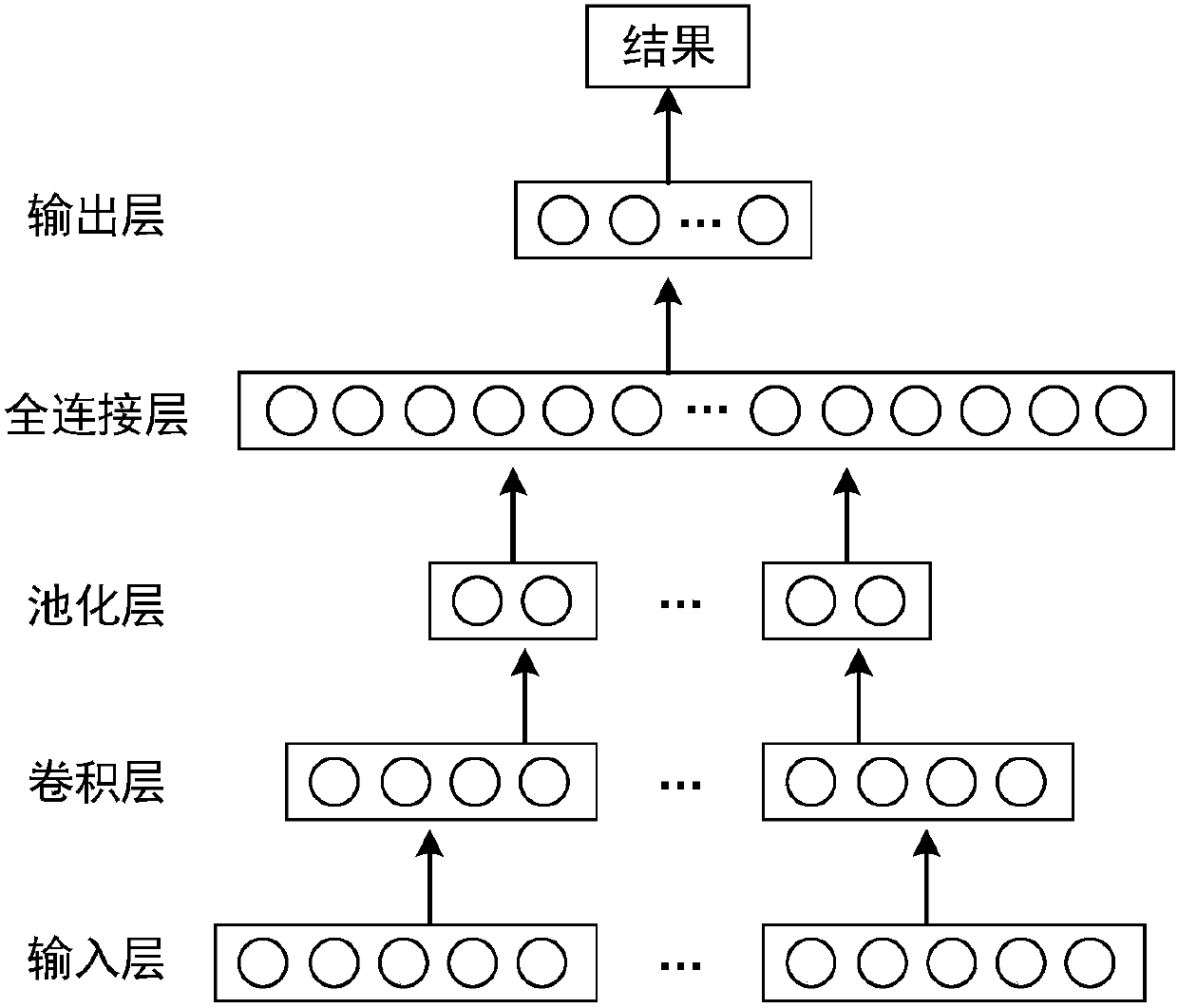

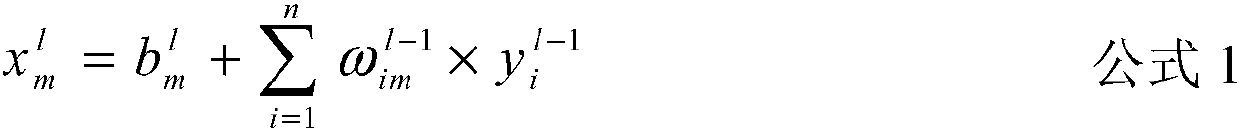

[0033] The present invention provides a deep learning-based fire prevention monitoring method for smoke in rail train equipment. The method relies on the convolutional neural network model in deep learning technology, combines industrial cameras and sensors, and collects rail locomotives collected by industrial cameras and smoke sensors. The multi-dimensional smoke data in the equipment room is used as the data input of the convolutional neural network model, and the judgment result of whether there is a fire in the current equipment room is finally obtained through the deep learning method. The concrete implementation process of the present invention is as figure 1 shown, including the following steps:

[0034] Step S10, acquiring collected smoke data, including smoke feature data and concentration data, wherein smoke feature data includes but not limited to texture feature data, color feature data, motion feature data and transformation feature data.

[0035] Audio and vide...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com