Flue-gas denitration pretreatment device for power plant utilizing agriculture and forestry waste

A monitoring device and high-temperature flue technology, which is applied in the separation of dispersed particles, chemical instruments and methods, separation methods, etc., can solve the problems that conventional technologies cannot directly deal with and cannot meet the needs of continuous production.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be further described below in conjunction with drawings and embodiments.

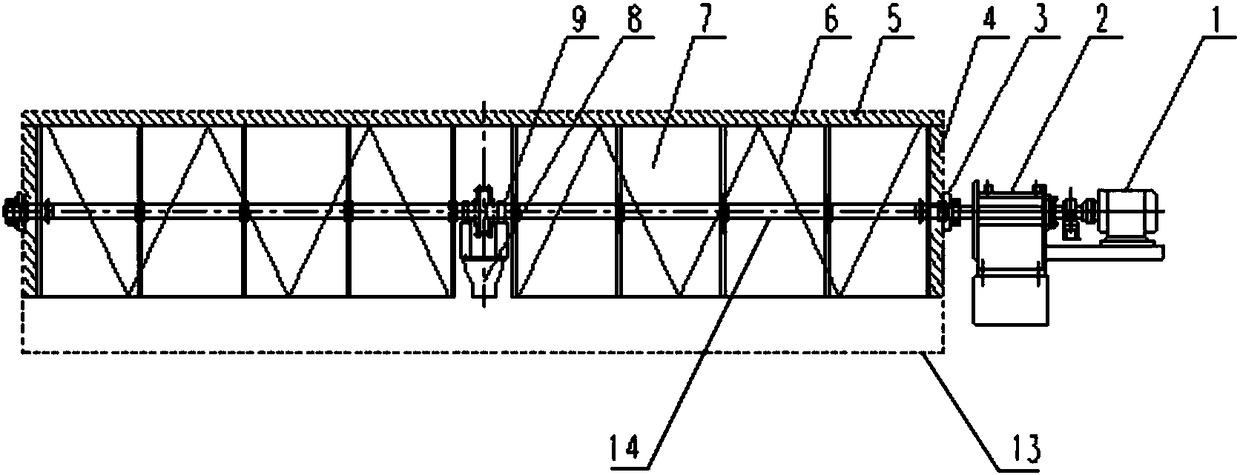

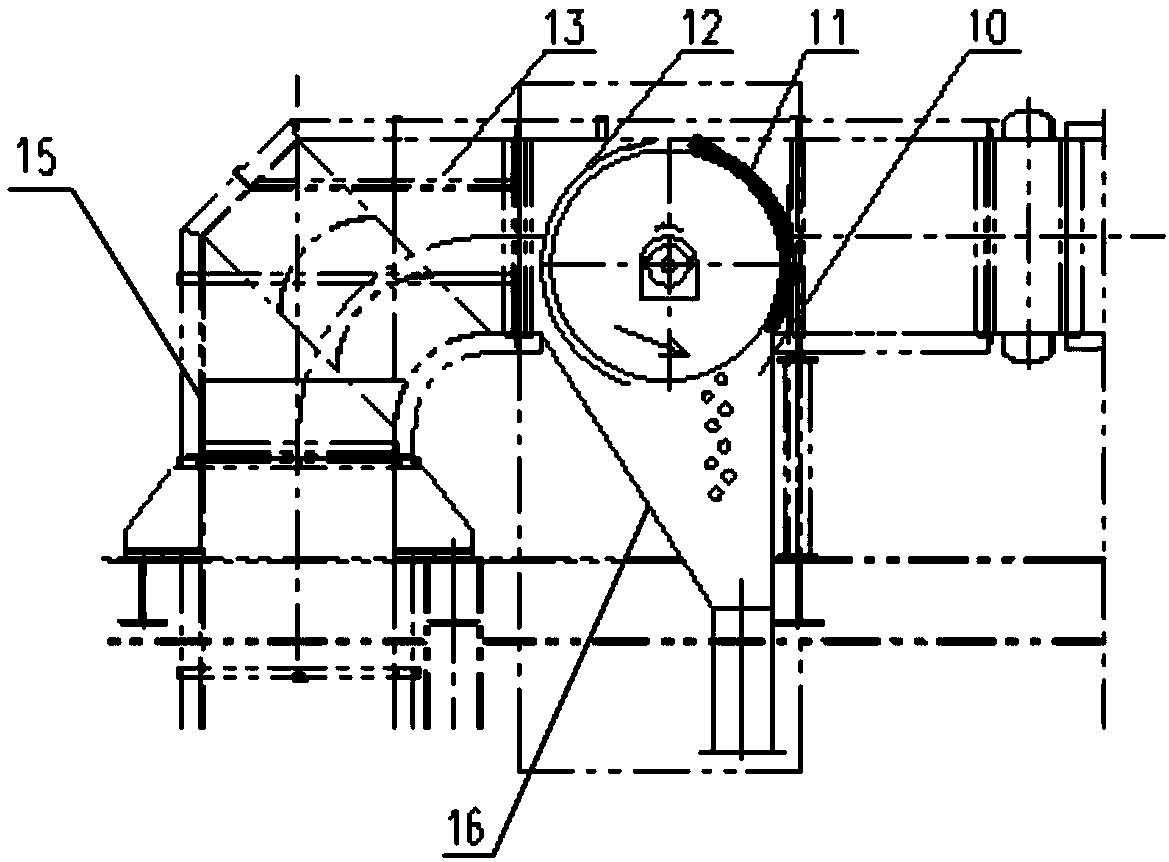

[0025] The invention provides a denitrification flue gas pretreatment device of an agricultural and forestry waste power plant, referring to figure 1 and figure 2 , including a horizontal high-temperature flue 13 communicating with the ascending flue 15, a drum screen is installed inside the high-temperature flue 13, and the drum screen includes a temperature-resistant rotating shaft 14, and is passed through a resistant rotating shaft 14 for supporting the temperature-resistant rotating shaft. temperature-resistant bearing bracket 8, and two pairs of cylindrical screens 7 fixed on the temperature-resistant rotating shaft 14, the temperature-resistant rotating shaft 14 is connected with the temperature-resistant bearing bracket 8 through the temperature-resistant roller bearing 9, the two The auxiliary cylindrical screen 7 is respectively located on both sides of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com