System for increasing inlet temperature of SCR denitration reactor by utilizing flue gas recirculation

A flue gas recirculation and denitration reactor technology, which is applied in gas treatment, chemical instruments and methods, dispersed particle filtration, etc. The effect of temperature increase, smoke emission reduction and investment saving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

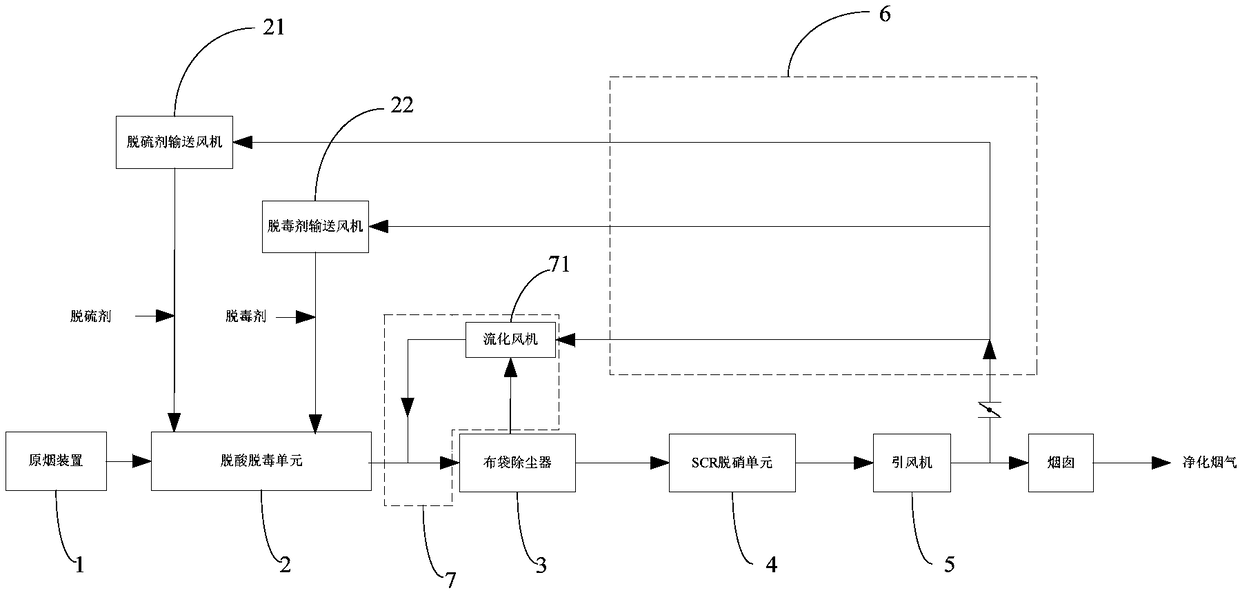

[0026] see figure 1 , the smoke inlet end of the flue gas recirculation pipeline 6 is led from the outlet flue of the bag filter 3; the flue gas deacidification and detoxification unit 2 includes a desulfurizing agent delivery fan 21 and a detoxification agent delivery fan 22; The bag filter 3 is provided with a fly ash circulation pipeline 7, and the fly ash circulation pipeline 7 is configured to allow the dust collected by the bag filter 3 to enter the flue upstream of the bag filter 3 again. The fly ash circulation pipeline 7 is provided with a fluidization fan 71 . The air inlets of the desulfurizing agent delivery fan 21 , the detoxification agent delivery fan 22 and the fluidization fan 71 are all connected to the smoke outlet end of the flue gas recirculation pipeline 6 .

[0027] The smoke inlet end of the flue gas recirculation pipeline 6 in this embodiment is led from the flue between the bag filter 3 and the SCR denitrification unit 4, and the waste heat flue gas ...

Embodiment 2

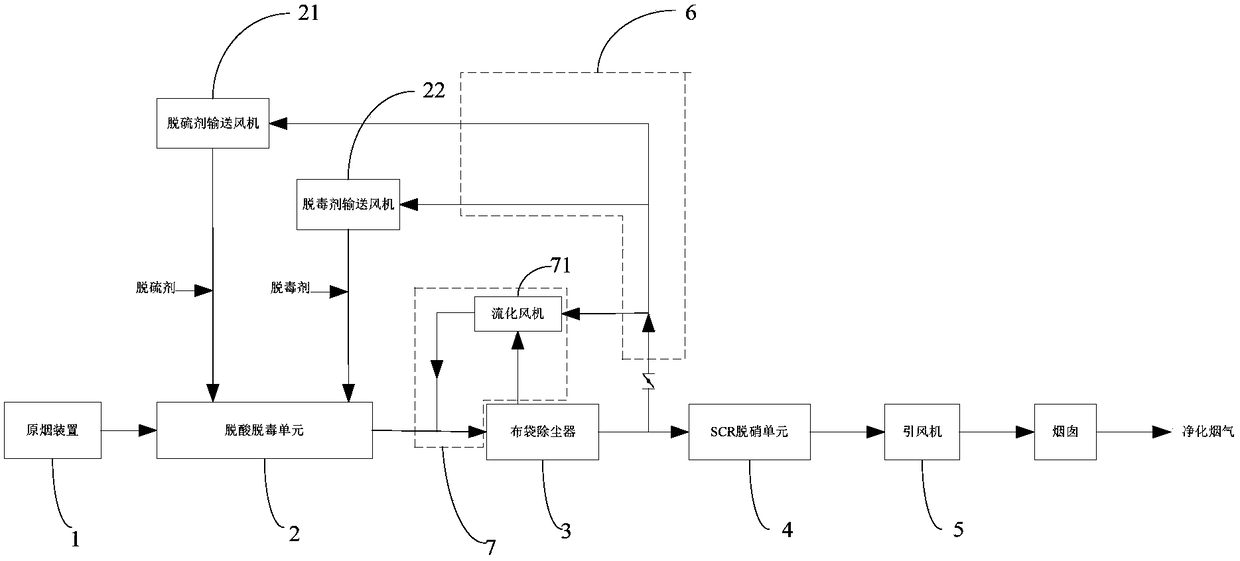

[0029] see figure 2 , the smoke inlet end of the flue gas recirculation pipeline 6 is drawn from the air outlet of the induced draft fan 5; the flue gas deacidification and detoxification unit 2 includes a desulfurizing agent delivery fan 21 and a detoxification agent delivery fan 22; The bag filter 3 is provided with a fly ash circulation pipeline 7, and the fly ash circulation pipeline 7 is configured so that the dust collected by the bag filter 3 enters the flue upstream of the bag filter 3 again. The ash circulation pipeline 7 is provided with a fluidization fan 71; the desulfurization agent delivery fan 21 and the detoxification agent delivery fan 22, and the air inlet of the fluidization fan 71 are all connected to the flue gas recirculation pipeline 6 The smoke outlet is connected.

[0030]The smoke inlet end of the flue gas recirculation pipeline 6 is led from the air outlet of the induced draft fan 5, and the waste heat flue gas at the air outlet of the induced draf...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com