Movable-type spraying dust removal system for long rod piece

A dust removal system and mobile technology, applied in the direction of cleaning methods using gas flow, paint spraying booths, spraying devices, etc., can solve the problems of high energy consumption and high power, and achieve the reduction of motor power, equipment cost and electric energy. Consumption, reduce the effect of bending deformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

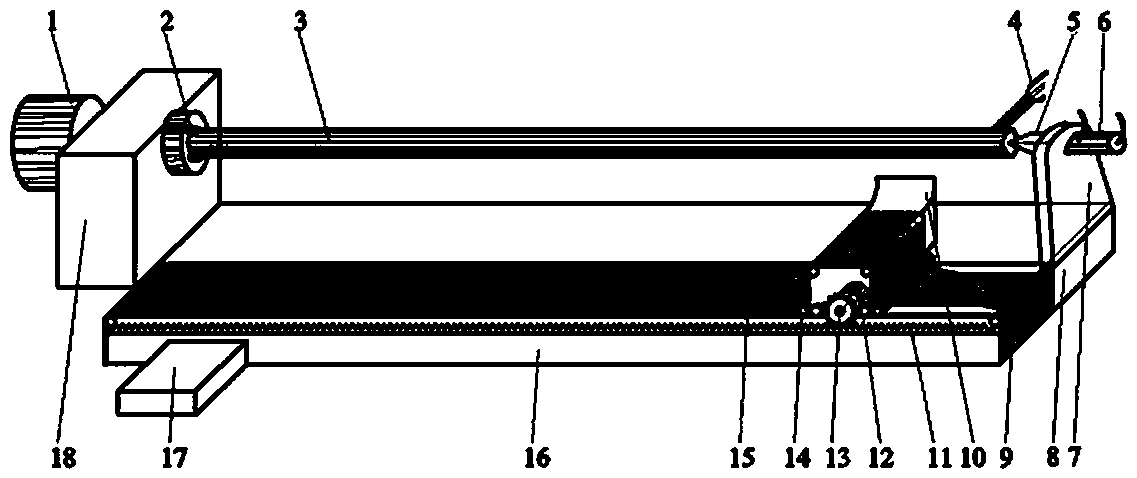

[0022] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

[0023] Such as figure 1 As shown, this embodiment is a mobile spraying and dust removal system for long rods, including a workbench 8, a dust collection box 10, a flexible rubber pad 15, an air duct 16, 2 pressing guide rollers, and 4 support Guide rollers;

[0024] Wherein, the left end of the worktable 8 is fixed with a turntable bracket 18, and the right end is fixed with a top bracket 7; the left side of the turntable bracket 18 is provided with a main speed regulating motor 1, and the right side is provided with a chuck driven by the main speed regulating motor 2. The top bracket 7 is provided with a rotatable movable top 5, and the right side is provided with a cylinder 6 for driving the movable top 5, and the seat of the cylinder 6 is fixedly connected with the top bracket 7 through a bracket. The central axis of the chuck 2 coincides with the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com