Fixing device of die changing equipment

A technology for fixing devices and equipment, which is applied to positioning devices, feeding devices, storage devices, etc., can solve the problems of uncompact structure, high cost, and many parts of the pneumatic clamping mechanism, and achieve compact structure, low cost, and simple mechanism. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

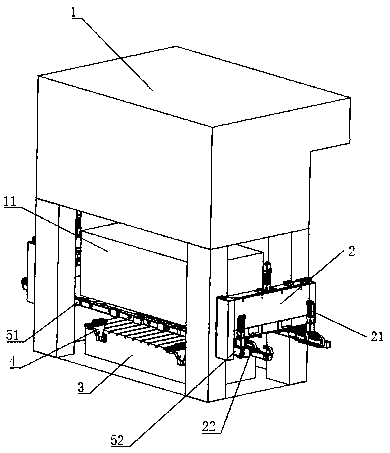

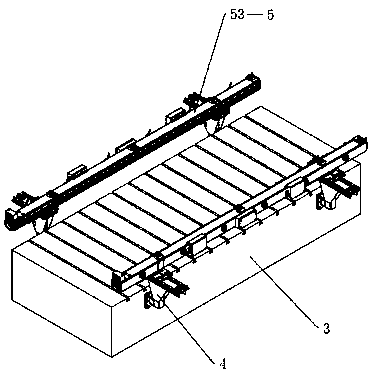

[0030] Example 1, such as figure 1 As shown, an automated stamping system includes a three-coordinate manipulator 2, a stamping machine 1 and a workbench 3 inside the press. Such as figure 2 As shown, there are several three-coordinate manipulators 2 on the left and right sides of the stamping machine 1 for connecting and driving the transmission rod 5 .

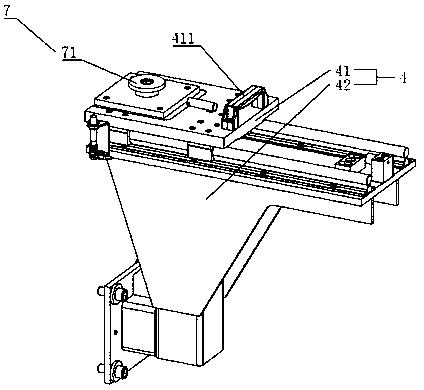

[0031] Such as figure 1 and figure 2 As shown, the docking platform 4 is installed on the side of the workbench 3 of the punching machine 1 . The three-coordinate manipulator 2 is provided with three electric cylinders 21 , and the electric cylinders 21 are provided with crawlers 22 . The crawler belt 22 is used to pull the transmission rod 5 to move in three directions respectively. For the specific structure and operation mode, refer to the Chinese patent with the patent number CN202278583U.

[0032] When the mold 11 needs to be replaced, the three-coordinate manipulator 2 pushes the two transmission rods 5 to move ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com