Vibration-isolating support type concrete manufacturer with blades provided with holes

A concrete and maker technology, which is applied to clay preparation devices, chemical instruments and methods, batching and batching instruments, etc., can solve the problems of concrete labor and other problems, and achieve good mixing effects, good vibration isolation effects, and good dust-proof effects.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

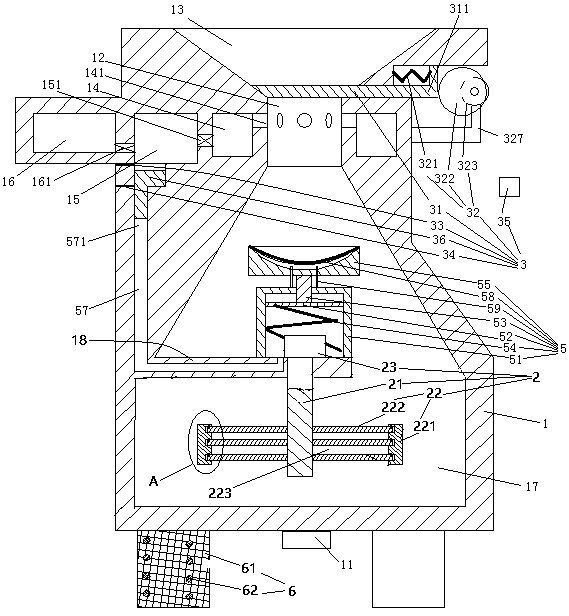

[0022] Embodiment one, see figure 1 , a concrete maker with perforated blades on vibration-isolation supports, including a container 1, a mixing mechanism 2 and an intermittent feeding control mechanism 3.

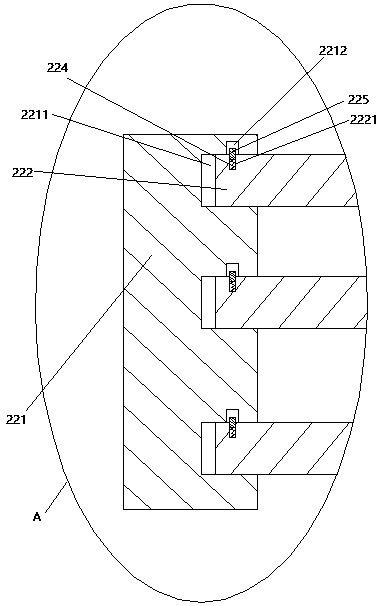

[0023]The lower end of the container 1 is provided with a shock-absorbing support pad 6 and a finished product outlet hole 11 . There are three damping support pads 6. Three shock-absorbing support pads 6 are distributed in a triangle. The vibration-damping support pad 6 includes a rubber block 61 and a coil spring 62 vulcanized in the rubber body. The top wall of the container 1 is provided with a material inlet hole 12 . The material inlet hole 12 is connected with an expansion bucket 13 . The container 1 is also provided with an annular water outlet channel 14 , an intermediate water chamber 15 and a water replenishment chamber 16 . The annular water outlet channel 14 extends along the circumferential direction of the material inlet hole 12 . The annular water out...

Embodiment 2

[0035] Embodiment two, the difference with embodiment one is:

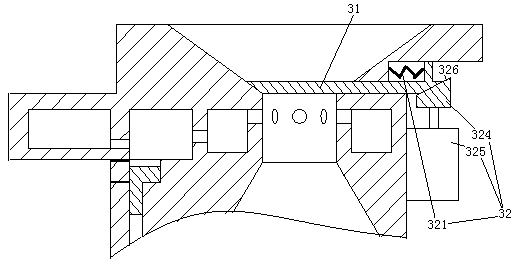

[0036] see image 3 , the driving mechanism 32 includes an outward push spring 321 , a transmission block 324 and a driving cylinder 325 . The structure and arrangement of the push-out spring 321 are the same as those in the first embodiment. The transmission block 324 is provided with a reversing slope 326 . The cross bar 311 abuts on the reversing slope 326 . The driving cylinder 325 expands and contracts in the up and down direction. The driving cylinder 325 is connected with the transmission block 324 to drive the transmission block 324 up and down. When the driving cylinder 325 drives the transmission block 324 to rise, the transmission block 324 drives the blocking plate 31 to close. When the driving cylinder 325 drives the transmission block 324 down, the blocking plate 31 is opened under the action of the outwardly pushing spring 321 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com