PET film

A technology of protective film and explosion-proof film, applied in synthetic resin layered products, layered products, chemical instruments and methods, etc., can solve the problems of short service life and single function, achieve long service life, broad application prospects, eliminate The effect of static electricity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

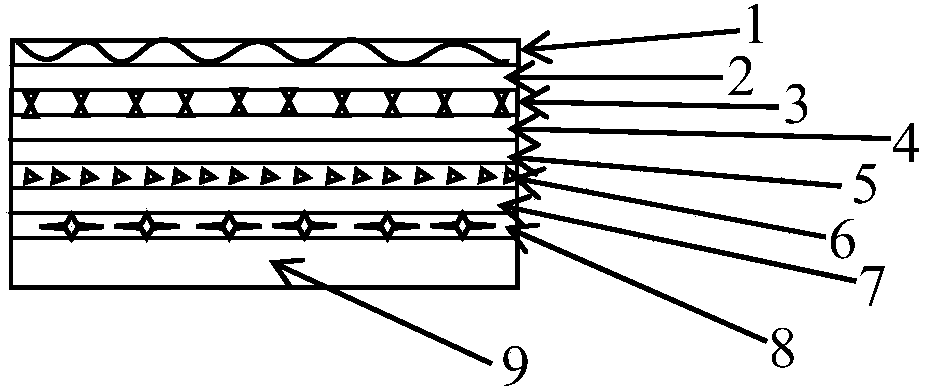

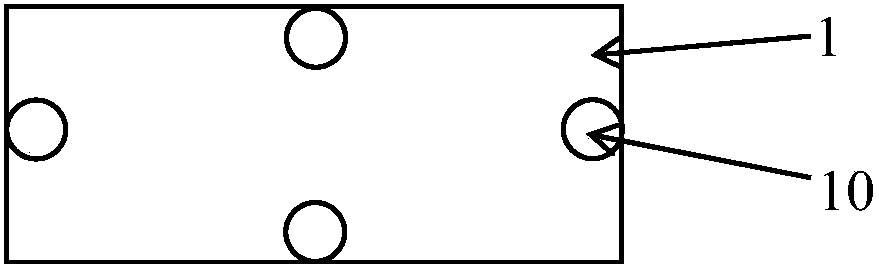

[0030] like Figure 1-2 As shown, a PET film includes a release film layer 1, and a PET protective film 2, a carbon nano layer 3, an explosion-proof film layer 4, and a nano heat insulation layer are sequentially arranged on the release film layer 1 in a layered manner. 5. Conductive layer 6, low-radiation film layer 7, anti-fingerprint protective layer 8 and waterproof layer 9. The above-mentioned film layers are prepared by existing processes or directly purchased from the market. The practicability is greatly improved and the functions are relatively perfect. PET protective film 2 , the sum of the thicknesses of the carbon nanolayer 3, the explosion-proof film layer 4 and the nano heat insulation layer 5 is the same as the sum of the thicknesses of the low-emissivity film layer 7, the anti-fingerprint protection layer 8 and the waterproof layer 9, and the conductive layer 6 is an aluminum foil layer. The conductive layer 6 realizes the conductive function, and a plurality o...

Embodiment 2

[0037] like figure 1 and 3 As shown, a PET film includes a release film layer 1, and a PET protective film 2, a carbon nano layer 3, an explosion-proof film layer 4, and a nano heat insulation layer are sequentially arranged on the release film layer 1 in a layered manner. 5. Conductive layer 6, low-radiation film layer 7, anti-fingerprint protective layer 8 and waterproof layer 9. The above-mentioned film layers are prepared by existing processes or directly purchased from the market. The practicability is greatly improved and the functions are relatively perfect. PET protective film 2 , the sum of the thicknesses of the carbon nanolayer 3, the explosion-proof film layer 4 and the nano heat insulation layer 5 is the same as the sum of the thicknesses of the low-emissivity film layer 7, the anti-fingerprint protection layer 8 and the waterproof layer 9, and the conductive layer 6 is an aluminum foil layer. The conductive layer 6 realizes the conductive function, and a plurali...

Embodiment 3

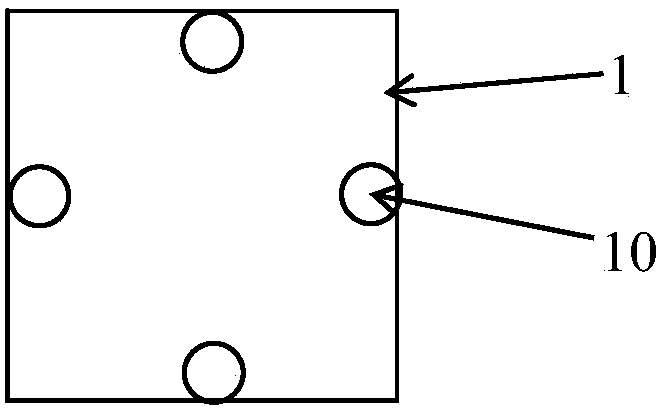

[0044] like figure 1 and 4 As shown, a PET film includes a release film layer 1, and a PET protective film 2, a carbon nano layer 3, an explosion-proof film layer 4, and a nano heat insulation layer are sequentially arranged on the release film layer 1 in a layered manner. 5. Conductive layer 6, low-radiation film layer 7, anti-fingerprint protective layer 8 and waterproof layer 9. The above-mentioned film layers are prepared by existing processes or directly purchased from the market. The practicability is greatly improved and the functions are relatively perfect. PET protective film 2 , the sum of the thicknesses of the carbon nanolayer 3, the explosion-proof film layer 4 and the nano heat insulation layer 5 is the same as the sum of the thicknesses of the low-emissivity film layer 7, the anti-fingerprint protection layer 8 and the waterproof layer 9, and the conductive layer 6 is an aluminum foil layer. The conductive layer 6 realizes the conductive function, and several t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com