A kind of heat-conducting pressure-sensitive adhesive tape and its preparation method and use method

A technology of pressure-sensitive tape and pressure-sensitive adhesive layer, applied in pressure-sensitive films/sheets, adhesives, epoxy resin adhesives, etc. The effect of manufacturing cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

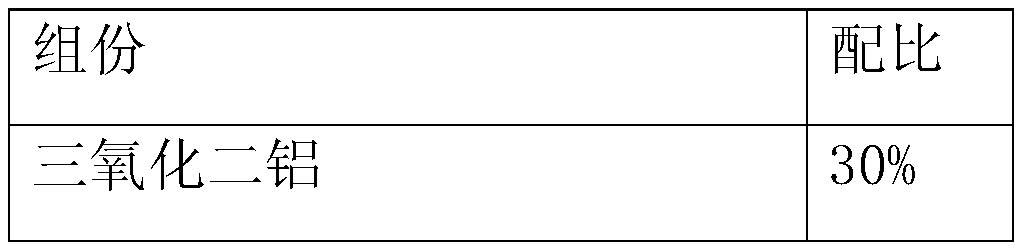

[0026] A method for preparing and using a heat-conducting pressure-sensitive adhesive tape, the mass percentage of each raw material is as follows:

[0027] Component Proportion Aluminum oxide 40% solvent 20% Modified Acrylic Resin 15% Normal temperature curing agent 1% Polyester polyol 15% Adhesion promoter 1% filler dispersant 2% Filler coupling agent 1% Closed Polyurethane Curing Agent 5%

[0028] First add aluminum oxide, solvent, filler dispersant, and filler coupling agent into the stirring tank, disperse at high speed for 3 minutes, then add the rest of the components into the stirring tank, and continue stirring for 40 minutes to prepare a heat-conducting pressure-sensitive adhesive; Use the heavy-release protective film as the coating substrate, coat the heat-conducting pressure-sensitive adhesive on it, dry it in a gradient oven at 50°C, attach the light-release protective film, and ripen for 0-7 day...

Embodiment 2

[0031] A method for preparing and using a heat-conducting pressure-sensitive adhesive tape, the mass percentage of each raw material is as follows:

[0032] Component Proportion fumed silica 30% solvent 25% Modified Acrylic Resin 15% Normal temperature curing agent 1% epoxy resin 20% Adhesion promoter 1% filler dispersant 2% Filler coupling agent 1% Epoxy curing agent 5%

[0033] First add fumed silica, solvent, filler dispersant, and filler coupling agent into the stirring tank, disperse at high speed for 10 minutes, then add the rest of the components into the stirring tank, and continue stirring for 40 minutes to prepare a heat-conducting pressure-sensitive adhesive; Use the heavy-release protective film as the coating substrate, coat the heat-conducting pressure-sensitive adhesive on it, and after drying in a gradient oven at 50°C, attach the light-release protective film; after 1-3 days of aging, that is ...

Embodiment 3

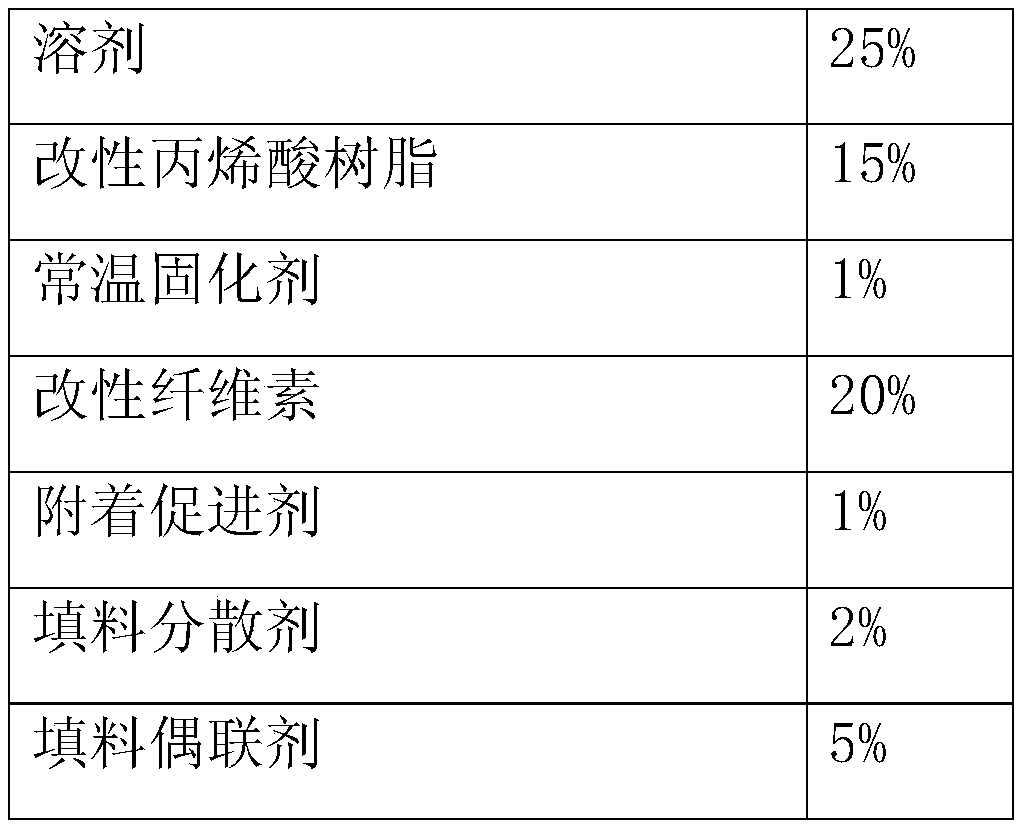

[0036] A method for preparing and using a heat-conducting pressure-sensitive adhesive tape, the mass percentage of each raw material is as follows:

[0037] Component Proportion Aluminum oxide 30% solvent 25% Modified Acrylic Resin 15% Normal temperature curing agent 1% UV curable resin 20% Adhesion promoter 1% filler dispersant 2% Filler coupling agent 1% light curing agent 5%

[0038] First add aluminum oxide, solvent, filler dispersant, and filler coupling agent into the stirring tank, disperse at high speed for 20 minutes, then add the rest of the components into the stirring tank, and continue stirring for 30 minutes to prepare a heat-conducting pressure-sensitive adhesive; The heavy-release protective film is used as the coating substrate, and the heat-conducting pressure-sensitive adhesive is coated on it. After drying in a gradient oven at 70°C, the light-release protective film is attached to obtain a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com