Preparation method of organic silicon pressure-sensitive adhesive

A technology of silicone pressure-sensitive adhesive and organic solvent, which is applied in the field of pressure-sensitive adhesive, can solve the problems of high equipment requirements and high energy consumption, and achieve the effects of simple preparation method, reduced investment and low cost

Pending Publication Date: 2022-02-25

HAISO TECH +1

View PDF31 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0007] In order to overcome the shortcomings of the existing traditional high-temperature vulcanized silicone pressure-sensitive adhesives, the present invention provides a method for preparing silicone pressure-sensitive adhesives, which does not use toxic carcinogenic or environmental pollution organic solvents such as toluene and xylene At the same time, there is no need for high-temperature reaction at 110°C or above or vacuum distillation, which reduces the resulting high equipment requirements, high energy consumption, and safety hazards.

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 1

[0036] In the formula of Example 1, N,N'-dicyclohexylcarboimide (DCC) was not added, and 150 kg of methyl isobutyl ketone was replaced with 150 kg of toluene, and at the same time, it was changed to reflux at 115° C. for 1 h, and the others remained unchanged.

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

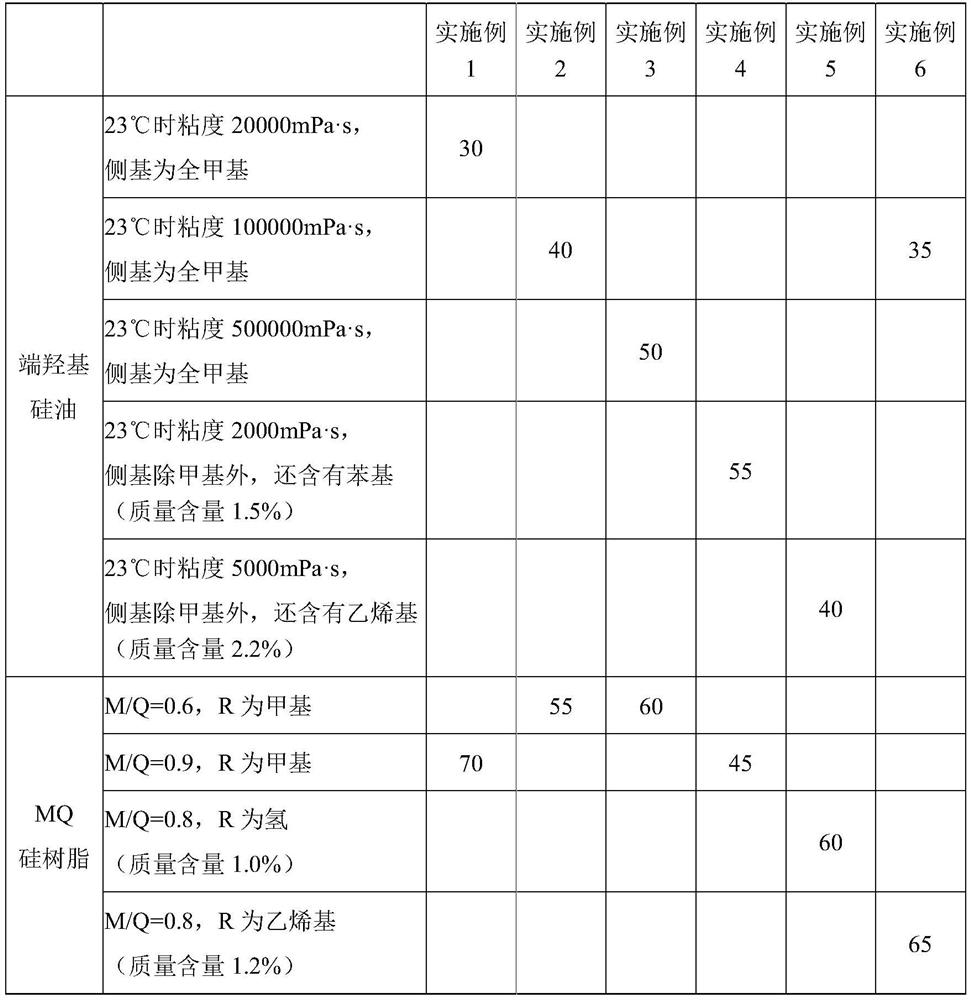

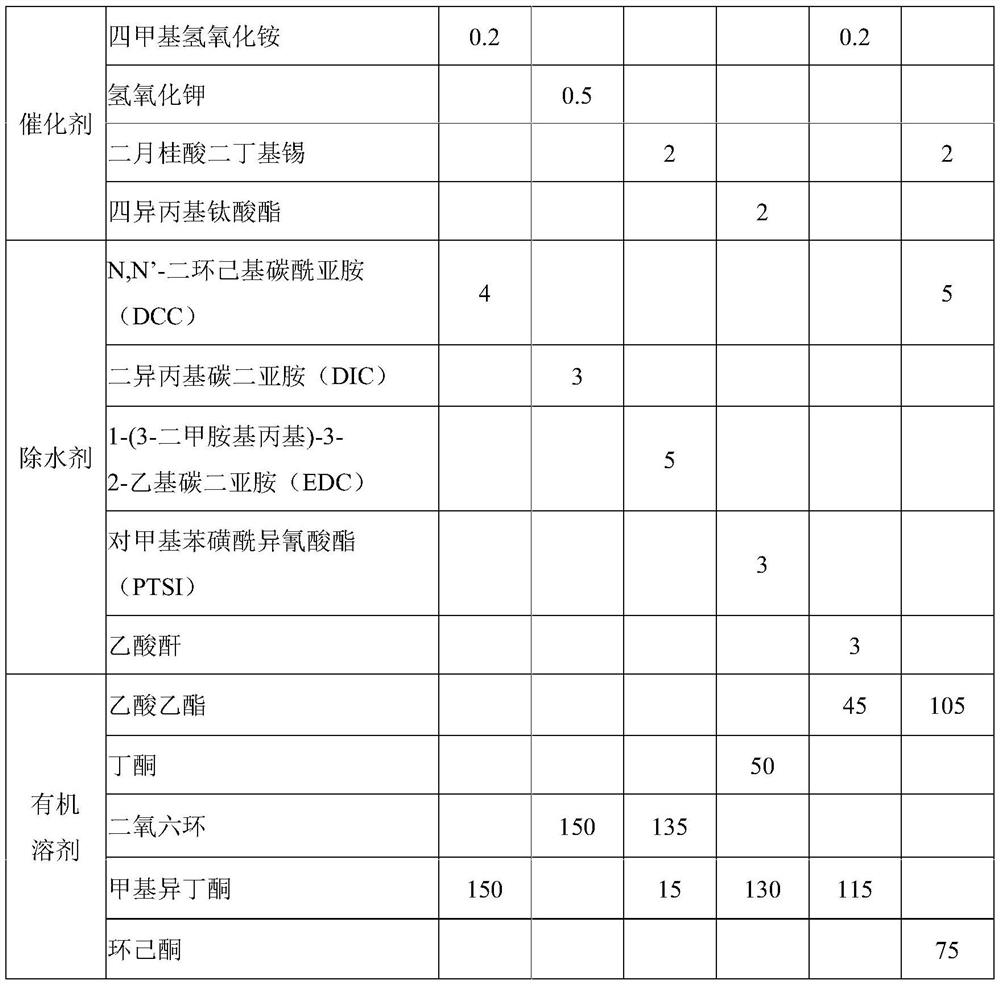

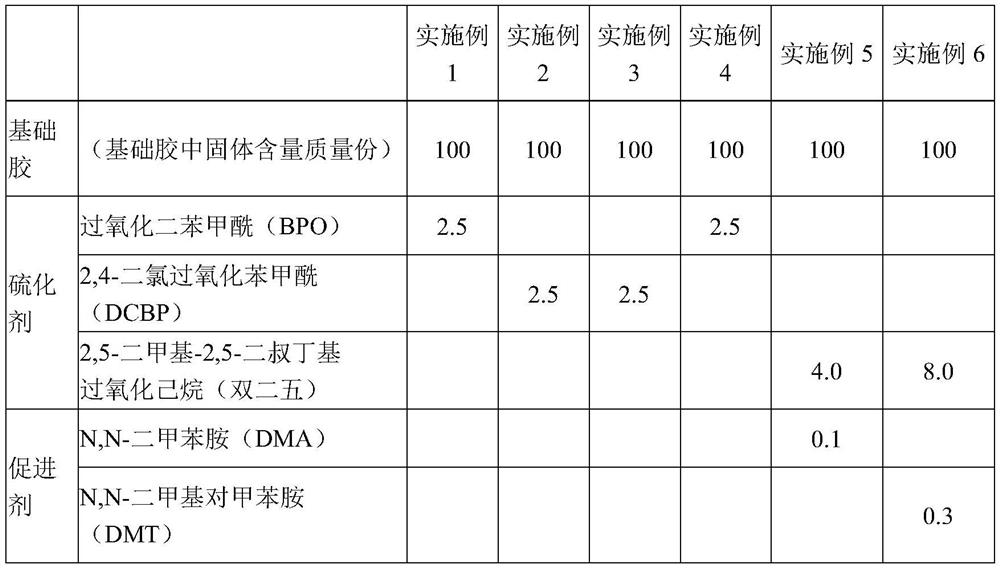

The invention discloses a preparation method of an organic silicon pressure-sensitive adhesive. The method comprises the following steps: 1) dissolving hydroxyl-terminated silicone oil and MQ silicon resin with an organic solvent with a boiling point or azeotropic point between 80 DEG C and 100 DEG C, adding a catalyst and a dewatering agent, carrying out a reflux reaction at 80-100 DEG C for 105 h, cooling to room temperature, and filtering to remove insoluble substances to obtain base rubber; and then adding a vulcanizing agent and an accelerant, and uniformly stirring at room temperature. The preparation method of the organosilicone pressure-sensitive adhesive is simple, toxic carcinogenic or environment-polluting organic solvents such as methylbenzene and dimethylbenzene are not used, meanwhile, the steps of high-temperature reaction at 110 DEG C or above or reduced pressure distillation and the like are not needed, and equipment investment, energy consumption and potential safety hazards are reduced.

Description

technical field [0001] The invention belongs to the field of pressure-sensitive adhesives, in particular to a method for preparing silicone pressure-sensitive adhesives. Background technique [0002] Silicone pressure-sensitive adhesive is a kind of high-quality and high-grade special pressure-sensitive adhesive, especially its high temperature resistance, adhesion to some low surface energy surfaces, electrical insulation and chemical inertness, etc. are not available for other types of pressure-sensitive adhesives. comparable. Therefore, this type of pressure-sensitive adhesive has been widely used to prepare medical tape or various high-temperature-resistant tapes, including wave soldering shielding film (gold finger tape) in the process of printed circuit boards, H-class electrical insulating tape, and mica tape for fire-resistant wires. and plating masking tape, etc. [0003] Silicone pressure-sensitive adhesives are usually made of permethyl-type or silicone rubber a...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): C09J183/04C09J183/05C09J183/07C09J11/06

CPCC09J183/04C09J11/06C08L2205/025C08L83/04C08K5/14C08K5/18Y02E60/10

Inventor 陈文求陈伟李桢林张雪平张文牛翔刘莎莎杨蓓范和平

Owner HAISO TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com