Carbonitriding method for thin-walled steel parts

A carbonitriding and steel technology, applied in coating, metal material coating process, solid-state diffusion coating, etc., can solve the problem of difficult to meet the requirements of use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

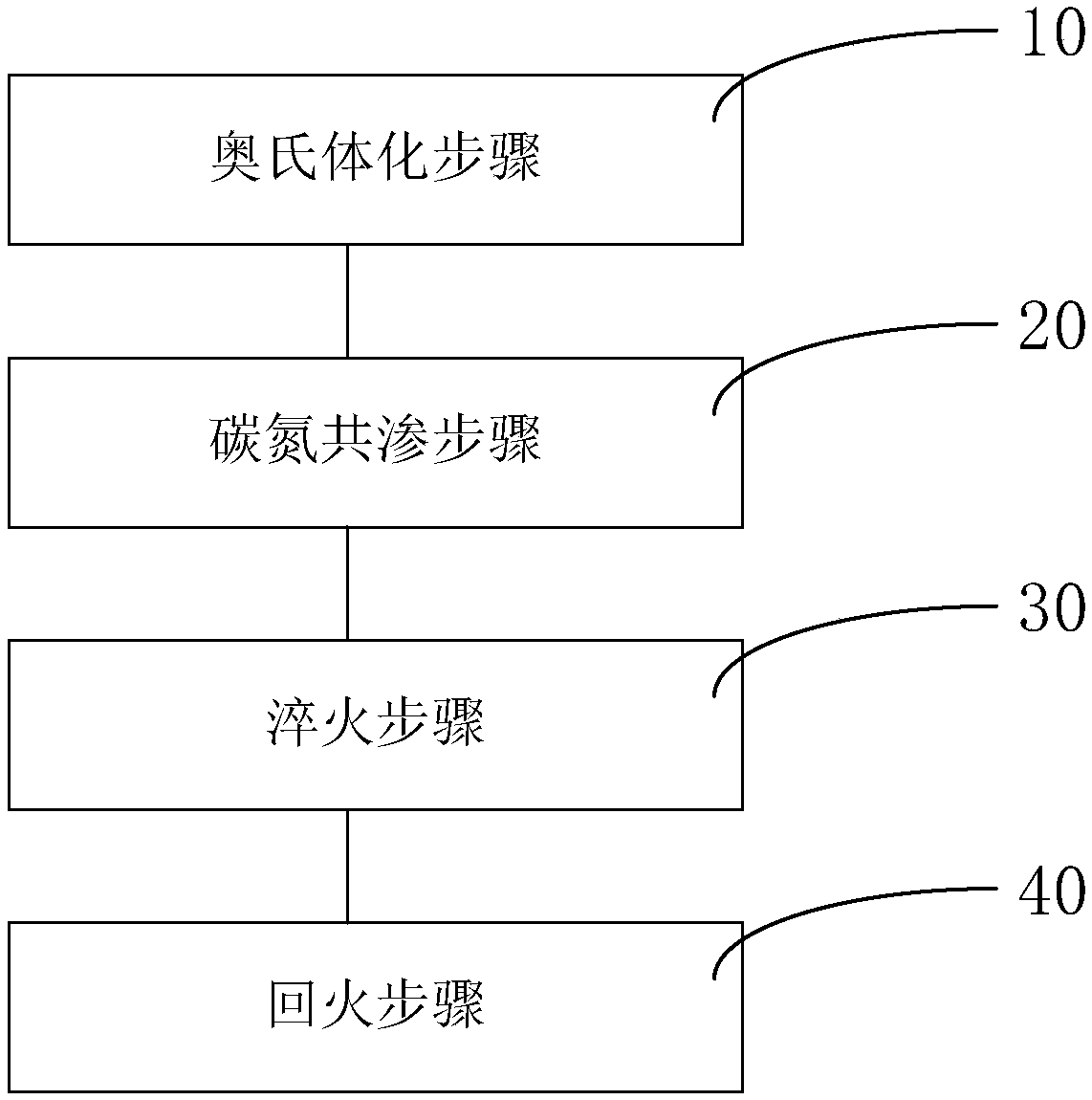

Method used

Image

Examples

Embodiment Construction

[0023] When the existing method is used for carbonitriding of thin-walled steel parts, the co-carburizing effect is not ideal.

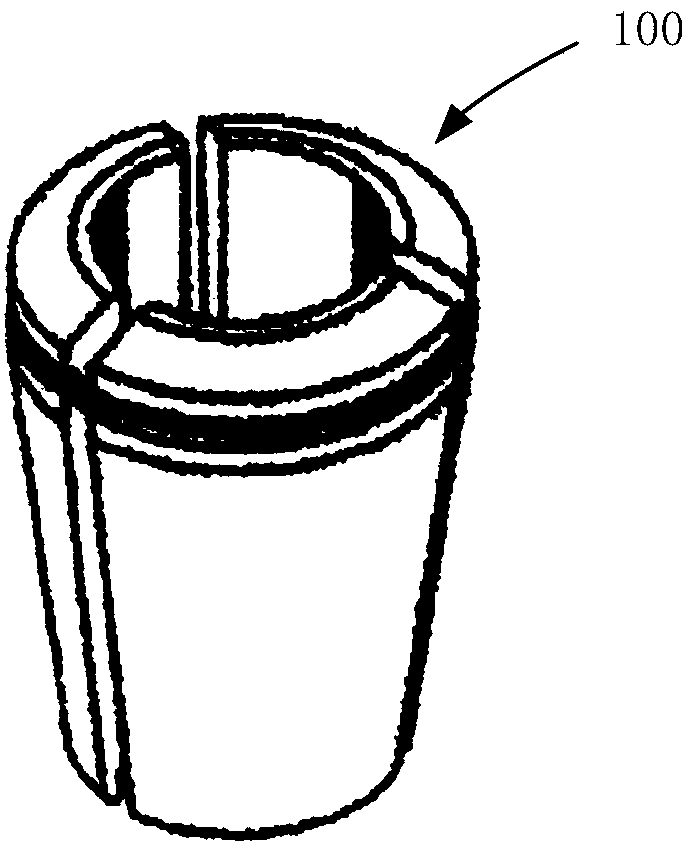

[0024] Thin-walled steel parts take the anchor clip in the clip anchor (YJM, anchor code: Y is prestressed, J is clip type, M is anchor) as an example. Clip anchor is a type of prestressed anchor used in prestressed structural engineering. It is widely used in long-span railways, highways, bridges, dams, construction projects and other geotechnical anchoring projects. The clip-type anchor is composed of anchor ring, anchor clip and anchor plate and other components. The anchor clip is a key element for directly clamping the prestressed steel strand, and its inner surface has inner teeth.

[0025] Usually, it is hoped that through carbonitriding, the surface of the anchor clip will be hard, the core will be tough, and the internal teeth will not break.

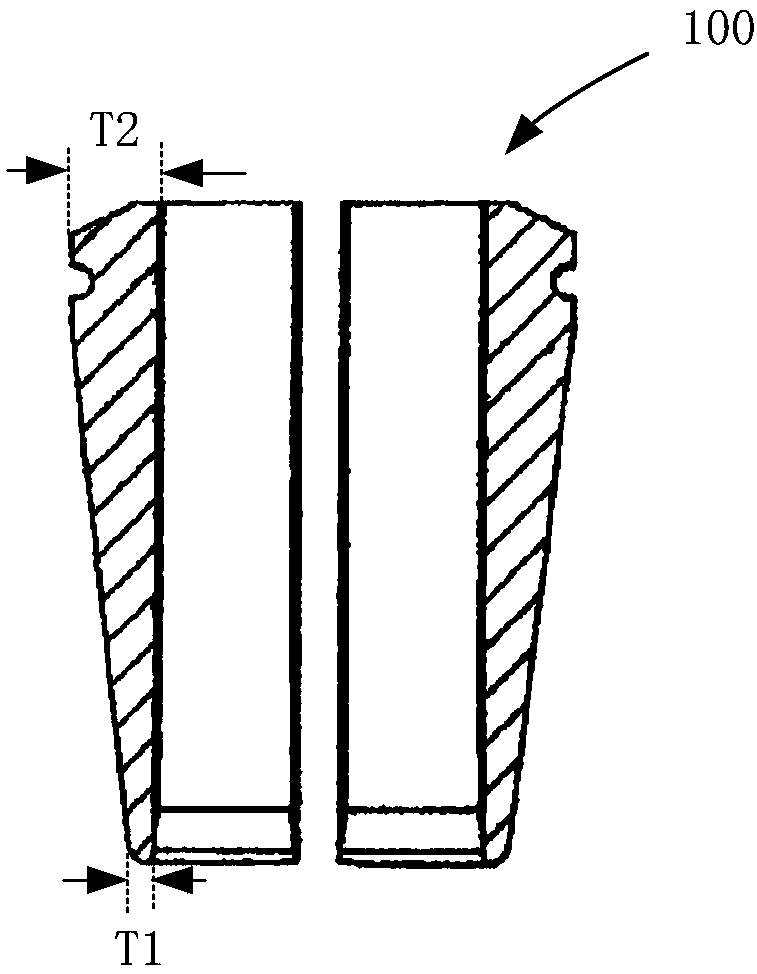

[0026] However, because the anchor clip is a small piece, the thickness of the side wall is thin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com