A Construction Method for Improving Internal Force Distribution of Large-span Connected-Span Hangar

A construction method and large-span technology, which can be applied to buildings and building structures, etc., can solve the problems of uneven distribution of structural system quality and internal force, and achieve the effects of balanced and continuous stiffness distribution, simple section selection, and reduction of peak internal force.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

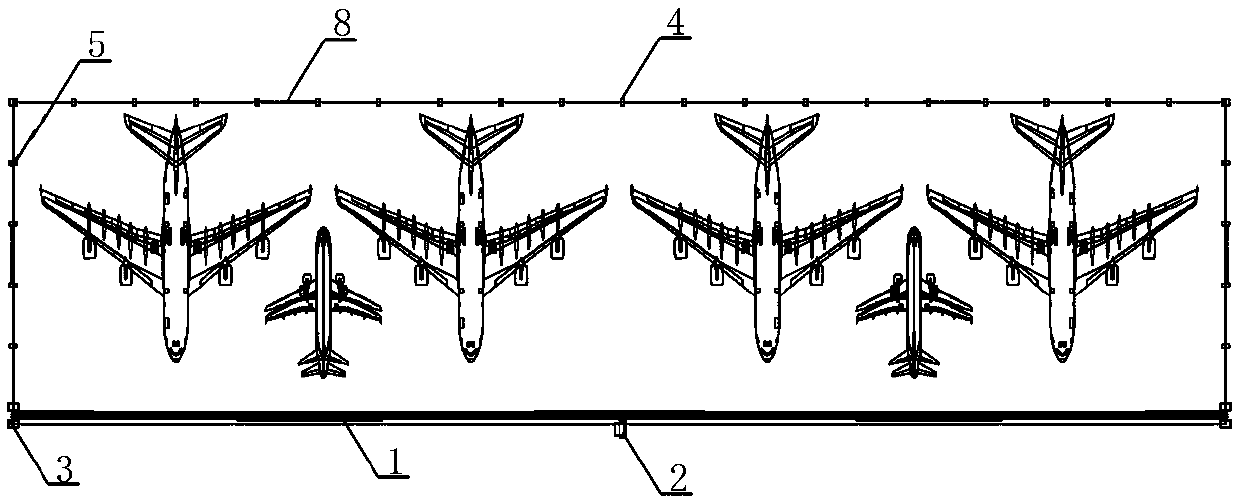

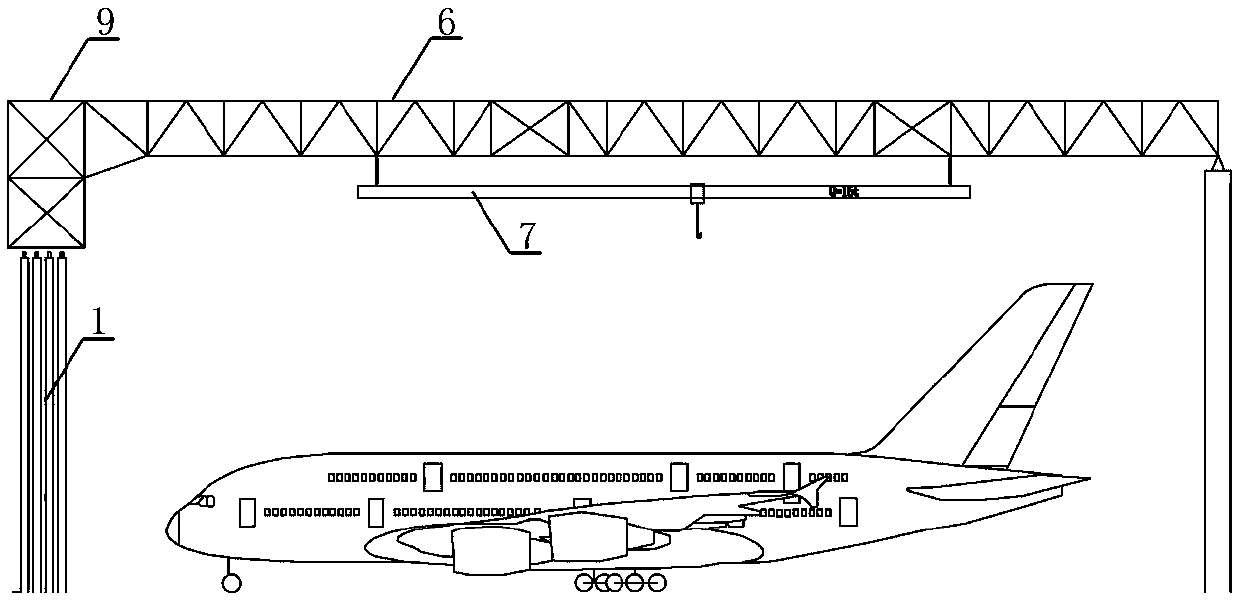

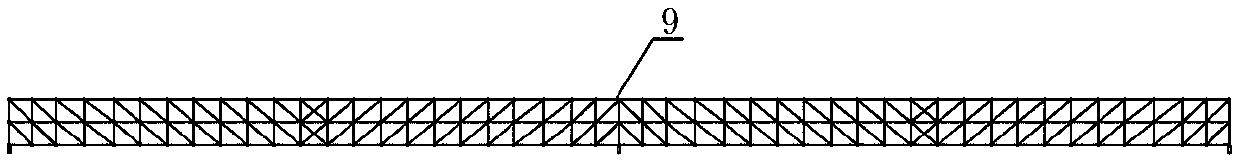

[0071] Examples see figure 1 , figure 2 , image 3 As shown, this construction method for improving the internal force distribution of a large-span even-span hangar, the front of the hangar is the hangar gate 1, including the gate side columns 3 on both sides of the gate and the gate center column 2 in the middle of the gate; The other three sides of the hangar are evenly spaced with support columns and inter-column support structures 8 connected between the support columns, wherein the support columns include rear gable support columns 4 and side wall support columns 5; the roof structure of the hangar includes roof The roof steel structure and the roof enclosure structure, wherein the roof steel structure includes the main frame of the roof and the gate truss 9, and the gate truss 9 is straddled and supported on the gate side column and the gate center column, and the specific steps are as follows:

[0072] Step 1, construct the support column, the side column of the gate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com