Superheat segment structure increasing input rate of high-pressure heater

A high-pressure heater and superheating section technology, which is applied in steam superheating, lighting and heating equipment, steam generation, etc., can solve the problems of soda water scouring, large tube wall scouring, and large free section length of tube bundles, etc., so as to prevent the steam flow rate from being too high , Improve the anti-scouring ability and reduce the effect of unsupported span

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be further described in detail below in conjunction with specific examples, but the implementation of the present invention is not limited thereto.

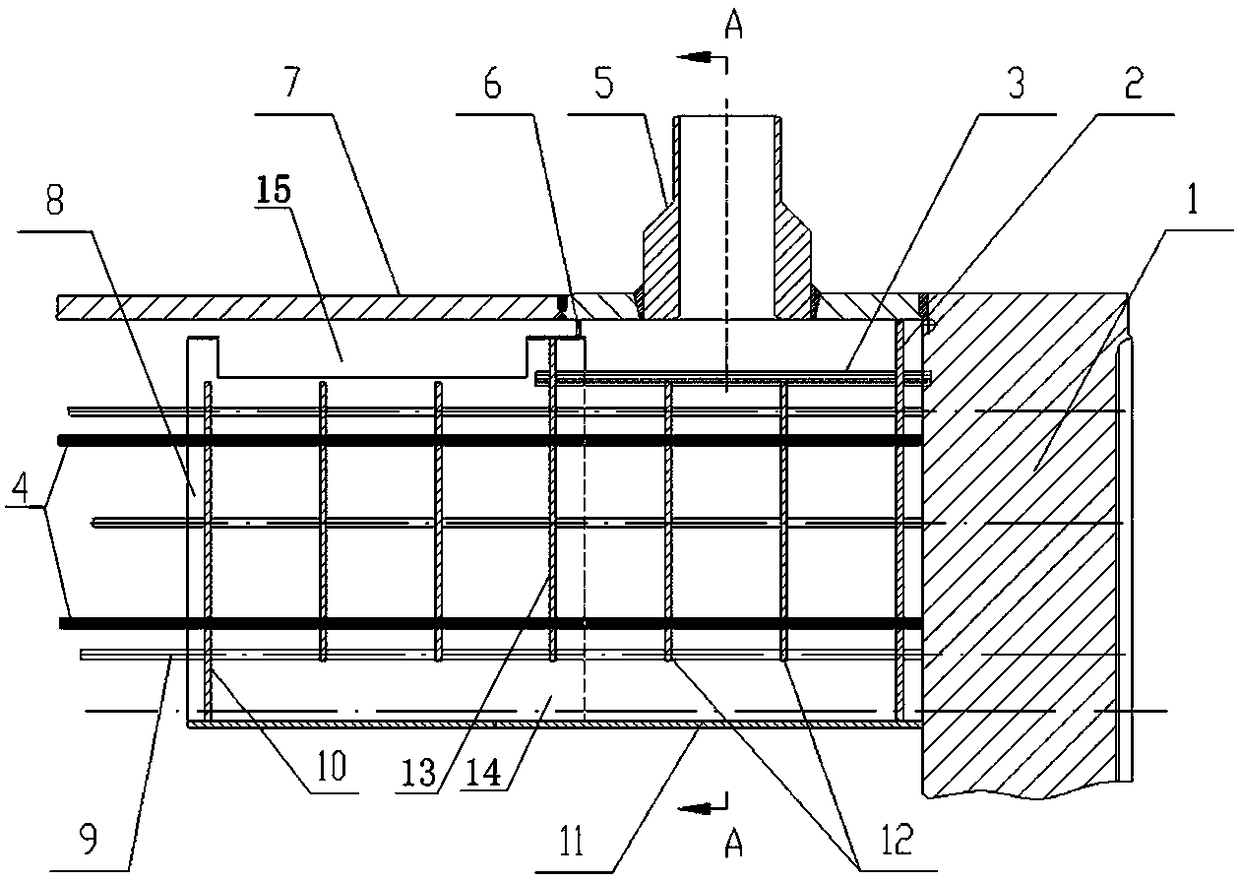

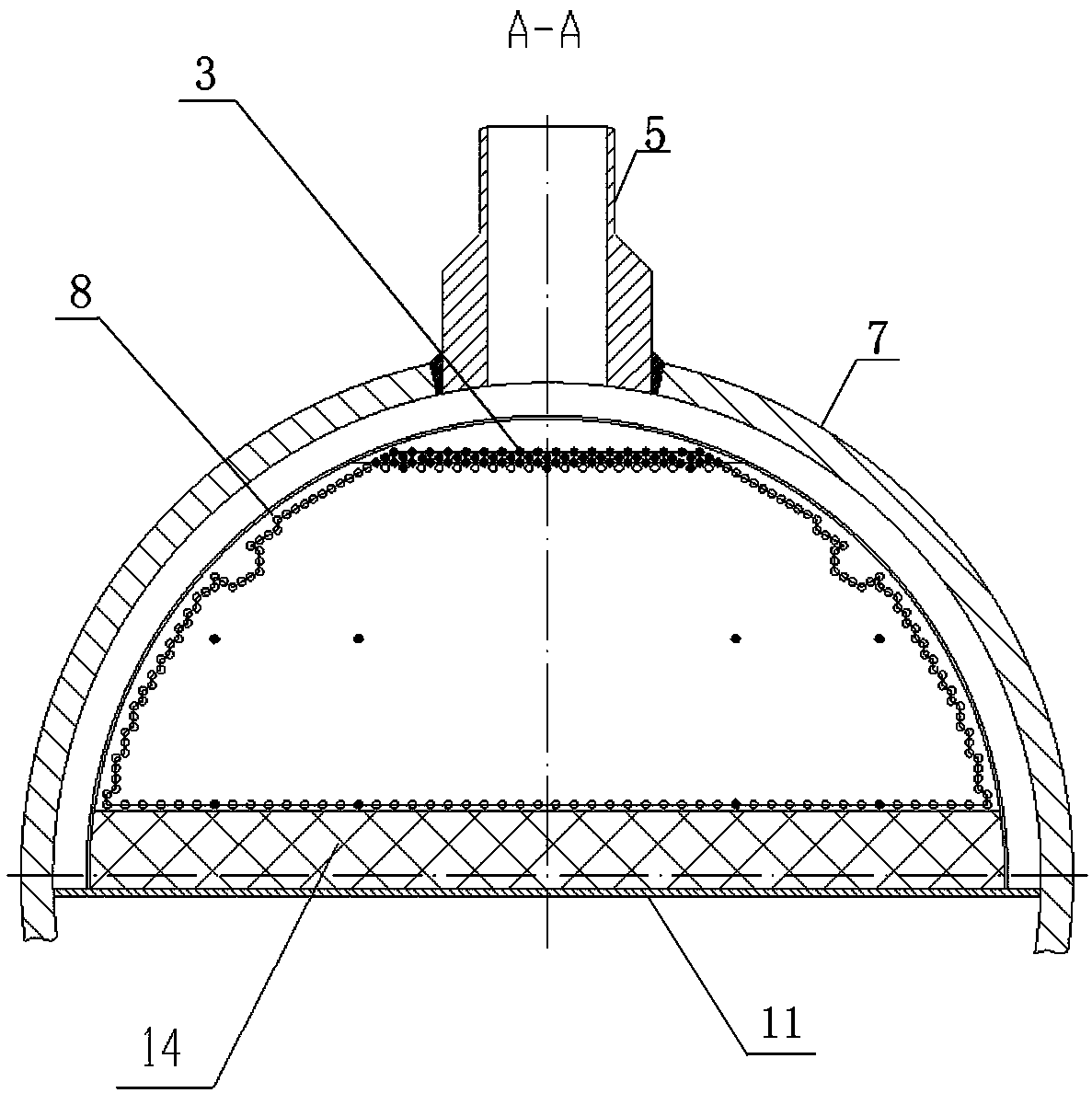

[0024] Such as Figure 1-4 As shown, a superheating section structure for improving the input rate of the high-pressure heater includes a shell 7, a tube plate 1 is arranged on one side of the shell 7, and a U-shaped tube 4 is arranged inside the shell 7, and the U-shaped tube 4 The ports are fixed on the tube sheet 1, and a heat shield 2 is arranged between the tube sheet 1 and the superheating section.

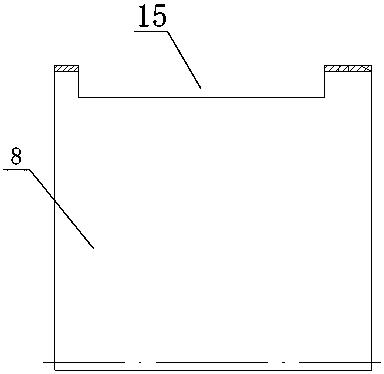

[0025] The superheating section is divided into a front section and an end section, the front section is provided with a steam inlet 5 , and the end section is provided with a cladding 8 . The steam inlet 5 is arranged on the shell 7 near the tube sheet 1, and below the steam inlet 5, above the U-shaped tube 4, a plurality of anti-shock bars 3 are arranged side by side, and the anti-shock bars...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com