Test method for testing resistance performance of antifouling coating in real sea environment

A technology of antifouling coating and testing method, which is applied in the field of testing, can solve problems such as unfavorable data collection stability and result analysis, and achieve the effects of improving the success rate of development, reducing development costs, and simple methods

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

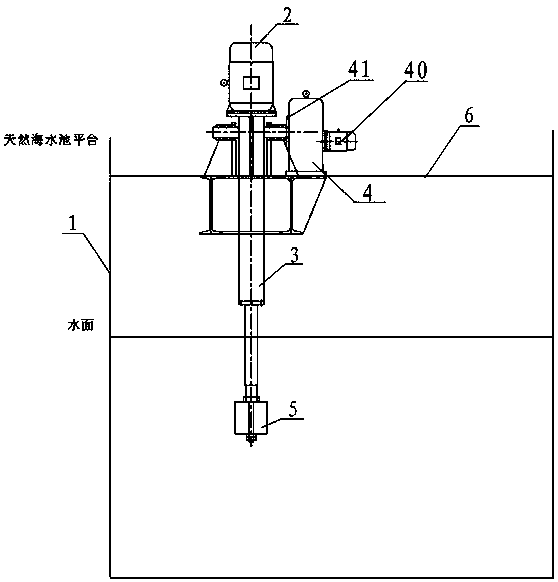

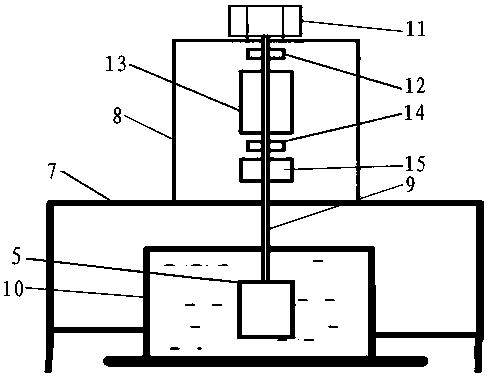

[0037] 1. Test conditions and test process:

[0038] 1.1. The real sea test is a natural environment, and the sample speed is controlled at 8-50 knots. At the same time, the real sea environment is monitored, such as seawater salinity, pH value, water temperature, etc.

[0039] 1.2. The actual sea test needs to make the surface of the sample reach a turbulent state, and the stop ratio is 1:30 to 30:1. Set the test rotation and rest time; according to the actual situation, it is also possible not to set the stop ratio .

[0040] 1.3. During the test, the torque of the sample can be monitored in real time or periodically, and the surface roughness of the coating can be measured.

[0041] 1.4. Process the test data, draw the working curve, and evaluate the resistance performance of the antifouling paint.

[0042] 1.5. In this embodiment, PVC is used as the sample substrate, and the cylindrical sample has a diameter of 200 mm and a height of 200 mm. Before coating the antifouli...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com