Device and method for simulating stress of annular tunnel tire-type lining supporting structure

A technology of supporting structure and lining, which is used in measuring devices, using stable tension/pressure testing materials, instruments, etc., can solve the problem that the real deformation of tunnel lining cannot be measured, it is difficult to have high convincing power, and the measurement location is difficult. and other problems, to achieve the effect of convenient operation, advanced technology and simple installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

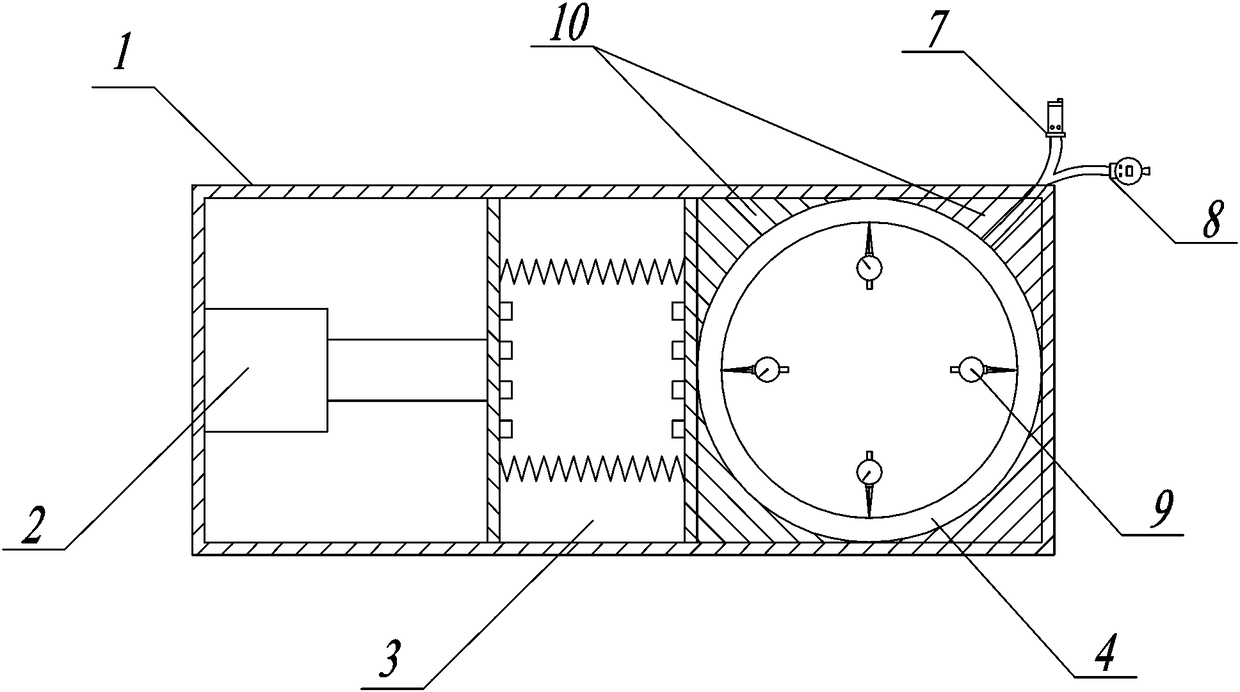

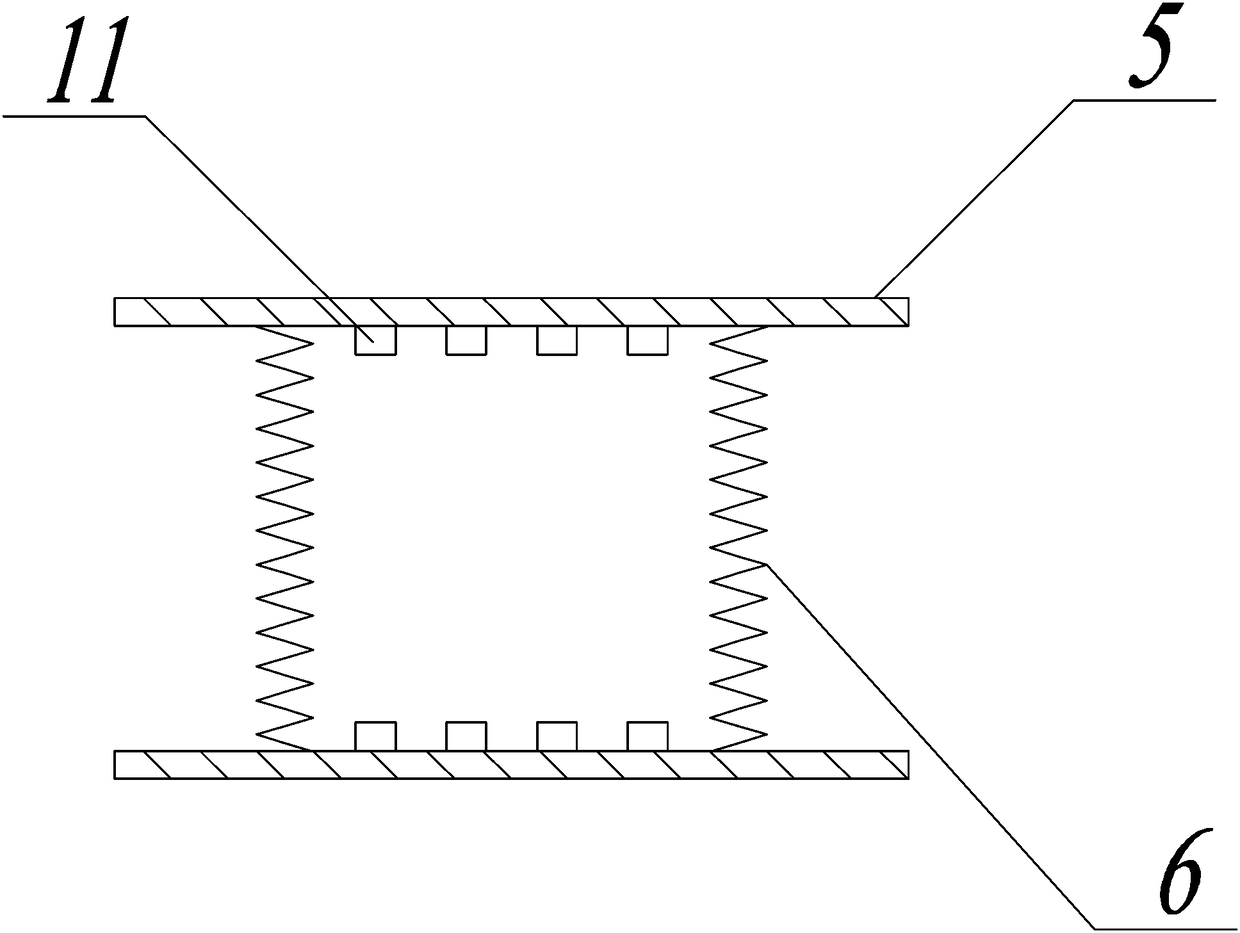

[0044] Such as Figure 1-7 As shown, a device for simulating the stress of the tire-type lining support structure of an annular tunnel includes a rectangular reaction frame 1, a jack 2 is arranged inside the rectangular reaction frame 1, and the base of the jack 2 is connected to the rectangular reaction frame 1. The inner side walls of the force frame 1 are in contact, and the top of the piston rod is in contact with the semicircular contour mold 10 through the force transmission device 3. There are two semicircular contour molds 10, which are symmetrically welded and fixed on the rectangular reaction force frame 1. Inside, the inner wall of the semicircular profile mold 10 is provided with a tire lining 4 in close contact with it. The pressure applied by the surrounding rock of the tunnel is simulated by the jack, and the force is transmitted to the tire lining by means of a force transmission device to simulate the actual force state of the tunnel lining.

[0045] Further,...

Embodiment 2

[0058] A test method for simulating the stress-bearing device of the tire-type lining support structure of an annular tunnel is characterized in that it comprises the following steps:

[0059] Step1: Preparation of the tire lining 4, the material of the carcass is changed from ordinary PVC to silicone rubber after several adjustments;

[0060] Step 2: Connect the automatic pressure relief valve 7 and the digital display air pressure gauge 8 with the carcass of the tire lining 4 as a whole, and fill the airtight carcass with gas;

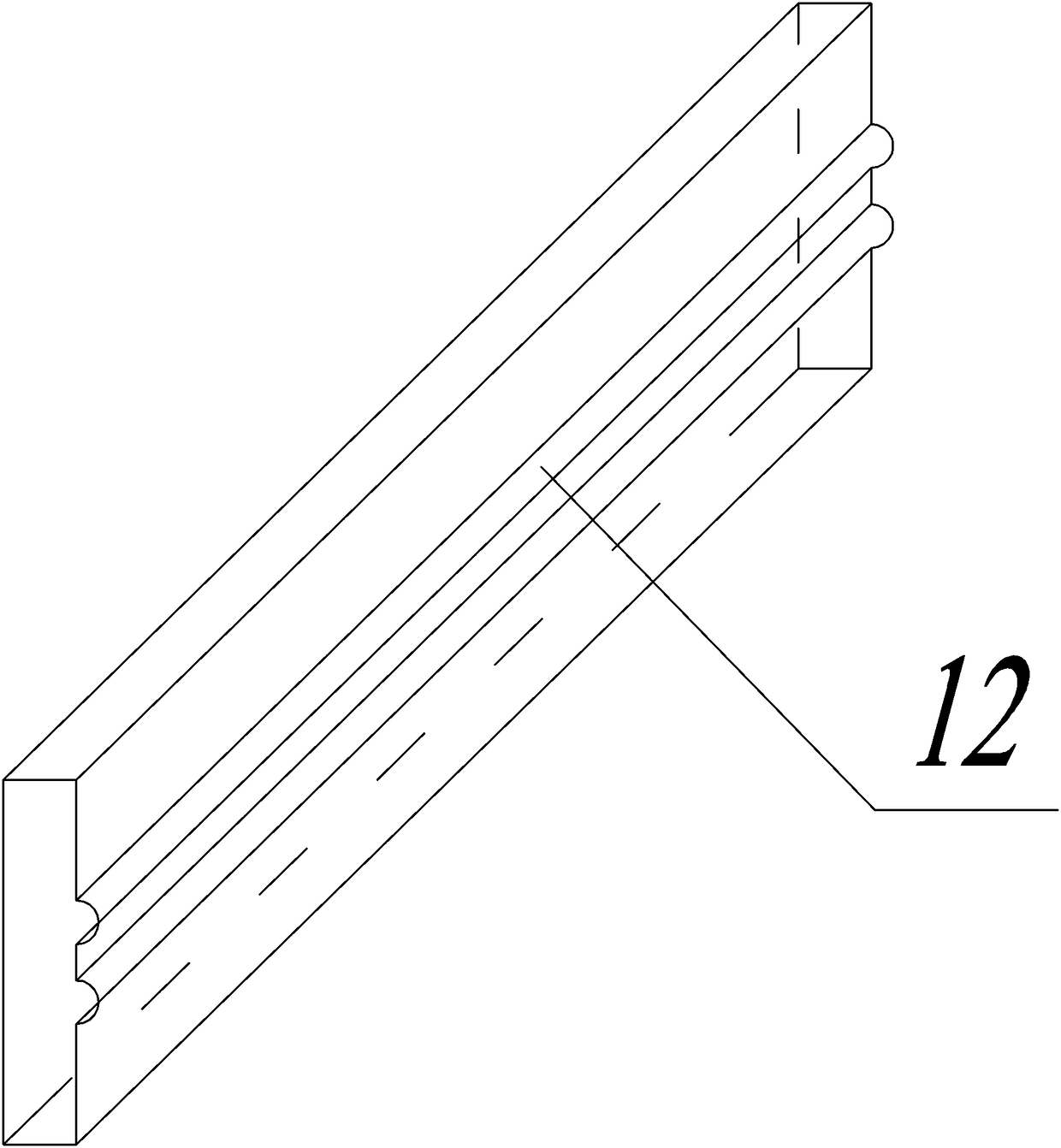

[0061] Step 3: Make a semicircular profile mold 10 as a lining arch ring, using a steel plate, and roll it into two arch rings;

[0062] Step 4: Paste the strain gauge, polish the surface of the lining arch ring and wipe it clean with alcohol, paste the strain gauge, weld the lead wire of the strain gauge to the wire with tin soldering, apply sealing glue, wrap it with insulating tape, and finally strain Sheet resistance measurement to detect the st...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com