Linear vibration motor

A linear vibration and motor technology, applied in the direction of electric components, casings/covers/supports, electrical components, etc., can solve the problems of low effective utilization of magnetic fields, insufficient magnetic field driving force of energized coils, poor insulation, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

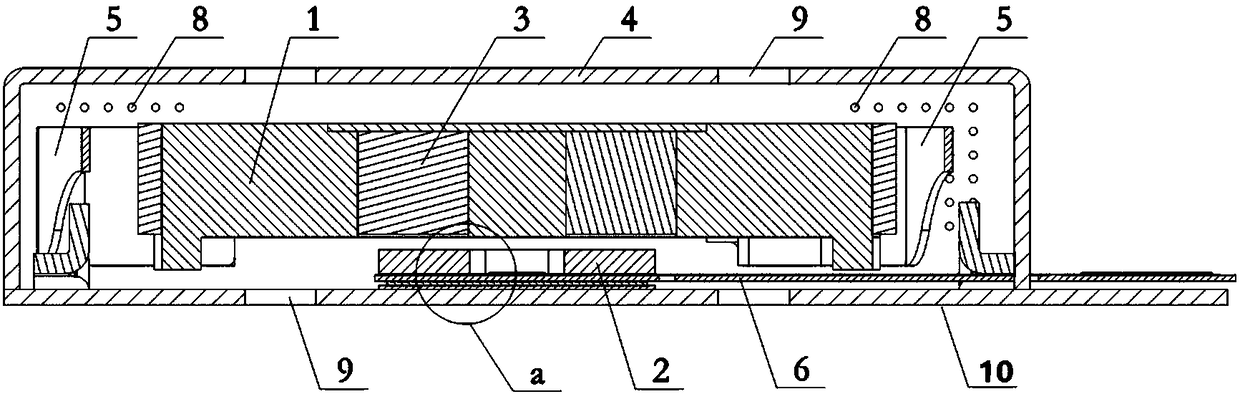

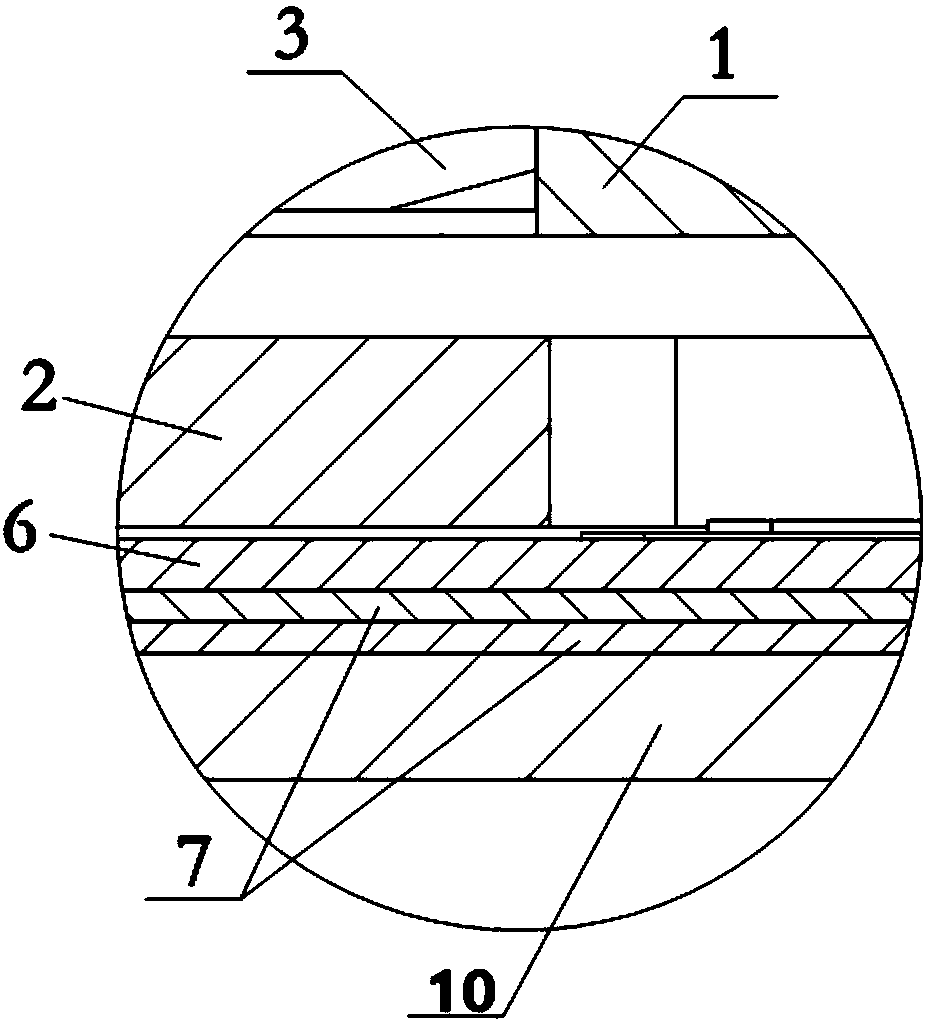

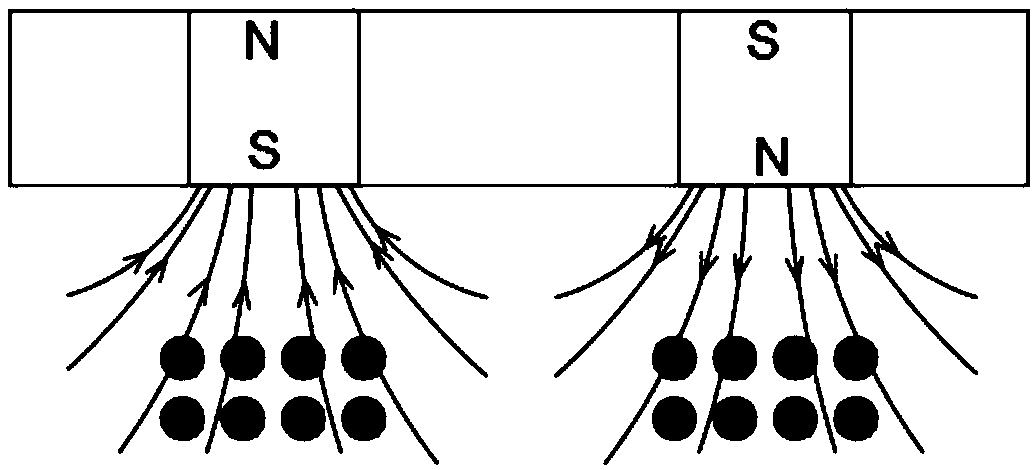

[0029] Such as Figure 1-2 As shown, a linear vibrating motor includes a casing 4 provided with an accommodation space, a vibrating assembly and a stator assembly. The casing 4 can be made of micro-magnetic material or SUS430 stainless steel, wherein the vibrating assembly and the peripheral surface of the stator assembly face each other. The two ends of the vibrating assembly are respectively elastically connected to the inner wall of the housing 4, and the stator assembly is fixedly connected to the inner wall of the housing space; a magnetically conductive sheet is also arranged between the stator assembly and the inner wall of the housing 4 7. The magnetic conductive sheet 7 can be made of ferrite material, such as SUS430 stainless steel, the thickness of the magnetic conductive sheet 7 can be 0.05mm-0.15mm, and the magnetic conductive sheet 7 can be installed by welding or glue bonding . The vibration assembly includes a mass block 1, a magnet 3 and two elastic elements ...

Embodiment 2

[0031] A linear vibration motor as described in Embodiment 1 may have multiple pieces of magnetically permeable sheets, and the multiple pieces of magnetically conductive sheets may be superimposed by welding. Preferably, two magnetically conductive sheets 7 can be stacked on the side of the flexible circuit board 6 facing away from the vibration component, and the two magnetically conductive sheets 7 can be stacked together by welding. The thickness of each magnetic conductive sheet 7 may be 0.03mm-0.1mm. Compared with Example 1, this Example 2 increases the number of magnetically conductive sheets, thereby enhancing the guiding effect on the magnetic induction lines, making the magnetic induction lines more concentrated, and further increasing the driving force when starting and the damping when stopping force. The magnetically permeable sheet 7 can also have one or more notches so as to avoid the wire ends entering and exiting the coil 2 .

Embodiment 3

[0033] A kind of linear vibrating motor as described in embodiment 1, 2, the bottom wall (that is cover plate 10) adjacent to the stator of its housing 4 is made by magnetically permeable material, such as micro magnetically permeable material, makes this cover plate 10 can also play the role of a magnetically conductive sheet. Compared with Embodiments 1 and 2, since the cover plate 10 of Embodiment 3 also acts as a magnetically conductive sheet, the guiding effect on the magnetic induction lines is further enhanced, and the magnetic induction lines are more concentrated, thereby increasing the Driving force at start and damping force at stop.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com