Actuator device

An actuator device and actuator technology, which are applied in the directions of fluid pressure actuation devices, forging/pressing/hammer devices, punching machines, etc., can solve the problem that the ejector device is not suitable for supporting the formed parts, and achieve a small cost. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

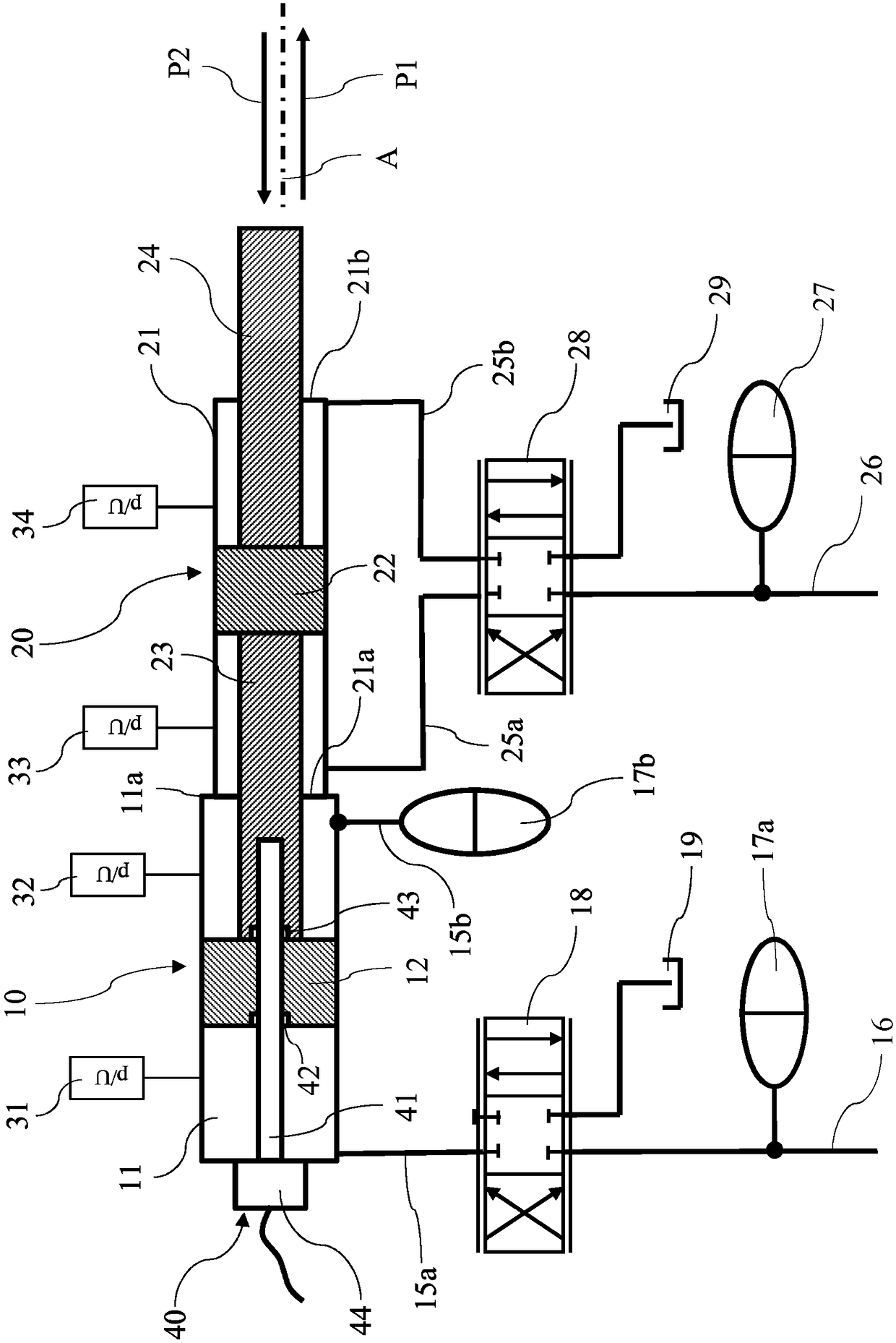

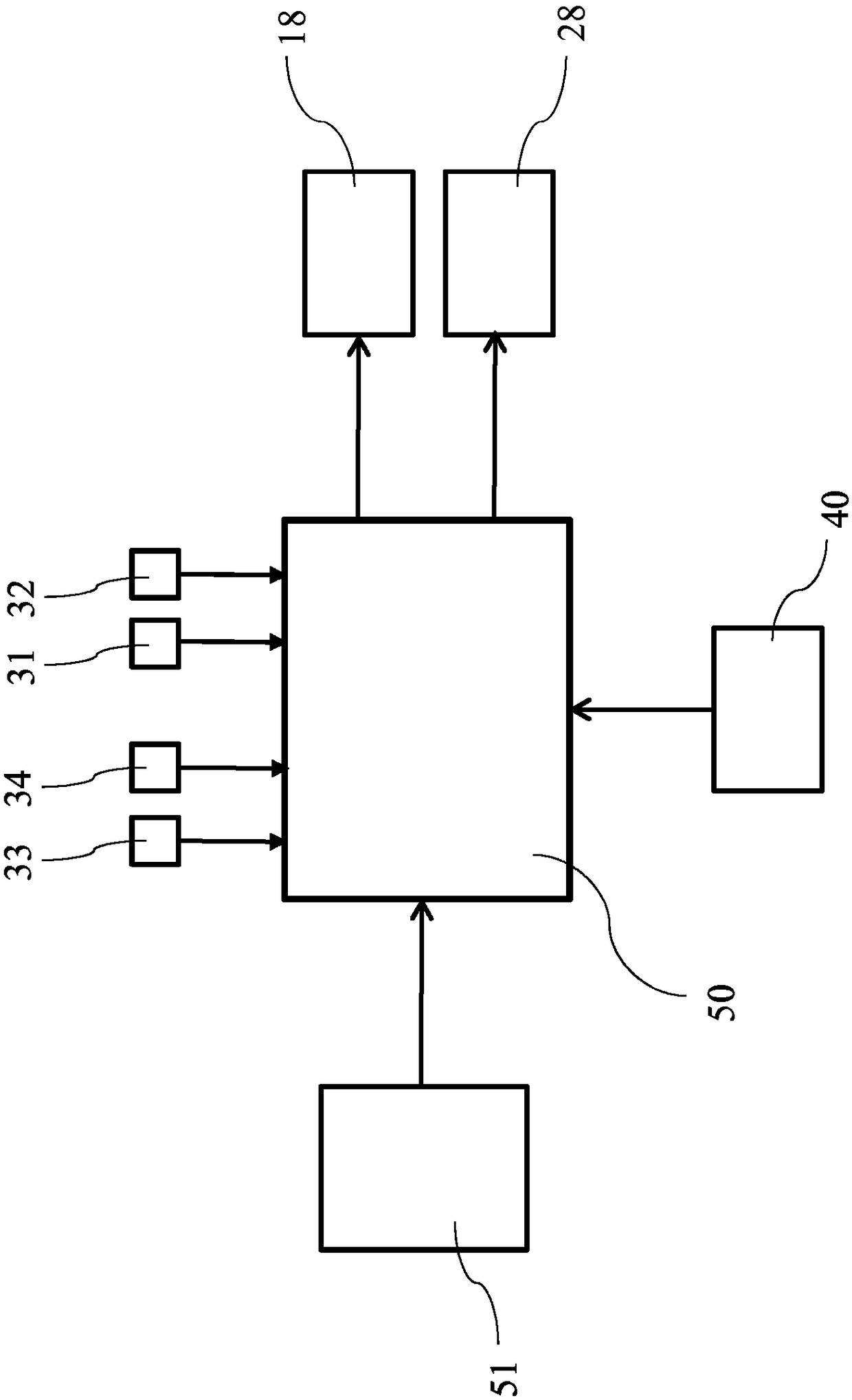

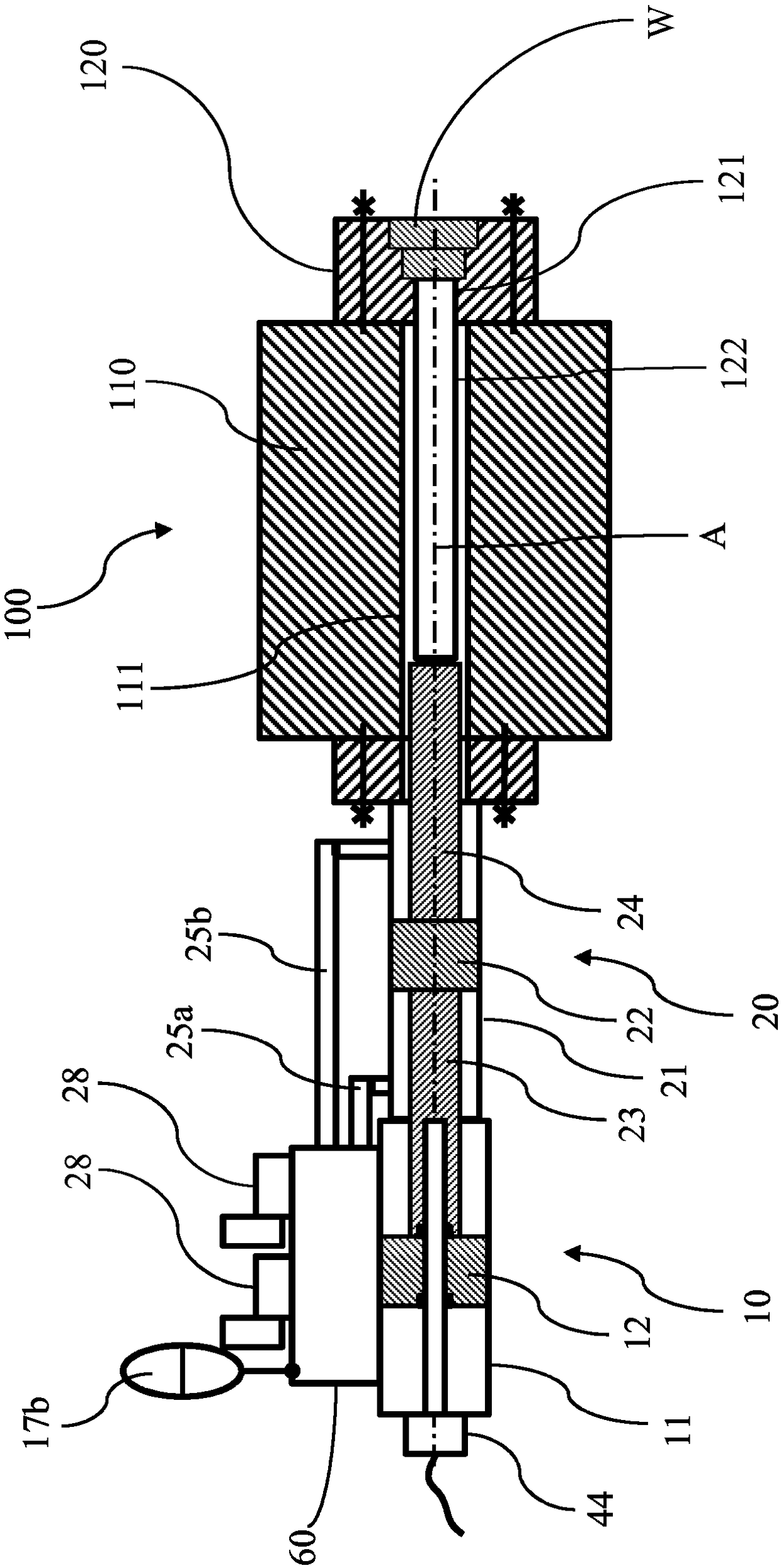

[0030] The actuator device according to the invention is in Figure 1-3 The embodiment presented in the most essential part for its function comprises a first drive unit 10 and a second drive unit 20 . The first drive unit 10 comprises an exemplary cylindrical piston chamber 11 having a linearly displaceable first piston 12 mounted therein. The second drive unit 20 comprises an exemplary cylindrical piston chamber 21 having a second piston 22 mounted linearly displaceably therein. The two piston chambers 11 and 21 are arranged flush next to each other with respect to the axis of movement A and are immovably connected to each other.

[0031] The first piston 11 is connected via two lines 15a and 15b to a first hydraulic mechanism comprising a hydraulic source symbolized only by line 16, two hydraulic accumulators 17a and 17b, for continuous operation Design the first 4-way servo valve 18 and sump 19. As explained further below, only three of the four paths of the servo valve...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com