Diffuser, design method of diffuser, manufacturing method of diffuser, display device, projection device, and lighting device

A design method and technology for diffuser plates, applied in the field of diffuser plates, can solve the problems of high production costs, a large amount of time required for comprehensive evaluation of results, and a large amount of data, and achieve the effects of excellent durability and excellent diffusion characteristics.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 approach

[0073] (About diffuser plate)

[0074] Below, refer to Figure 1 ~ Figure 7B The diffuser plate 1 according to the first embodiment of the present invention will be described in detail.

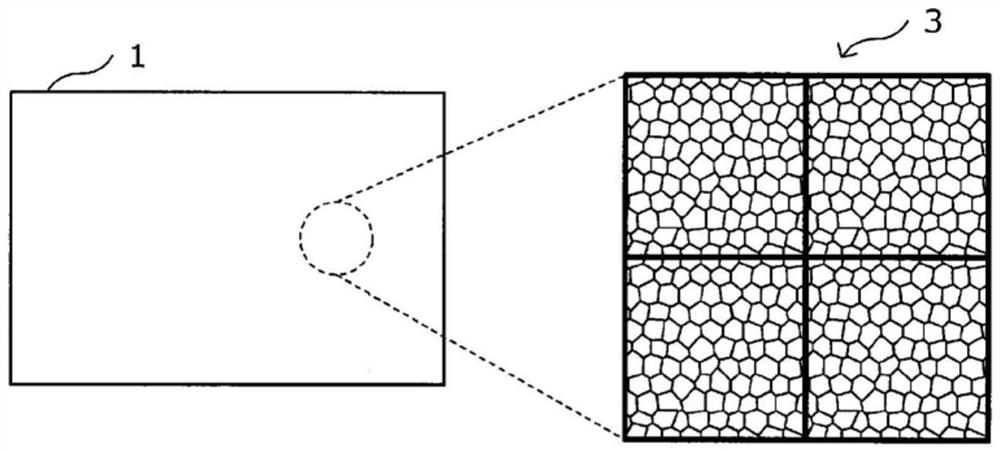

[0075] figure 1 It is an explanatory diagram schematically showing the diffusion plate according to the first embodiment of the present invention.

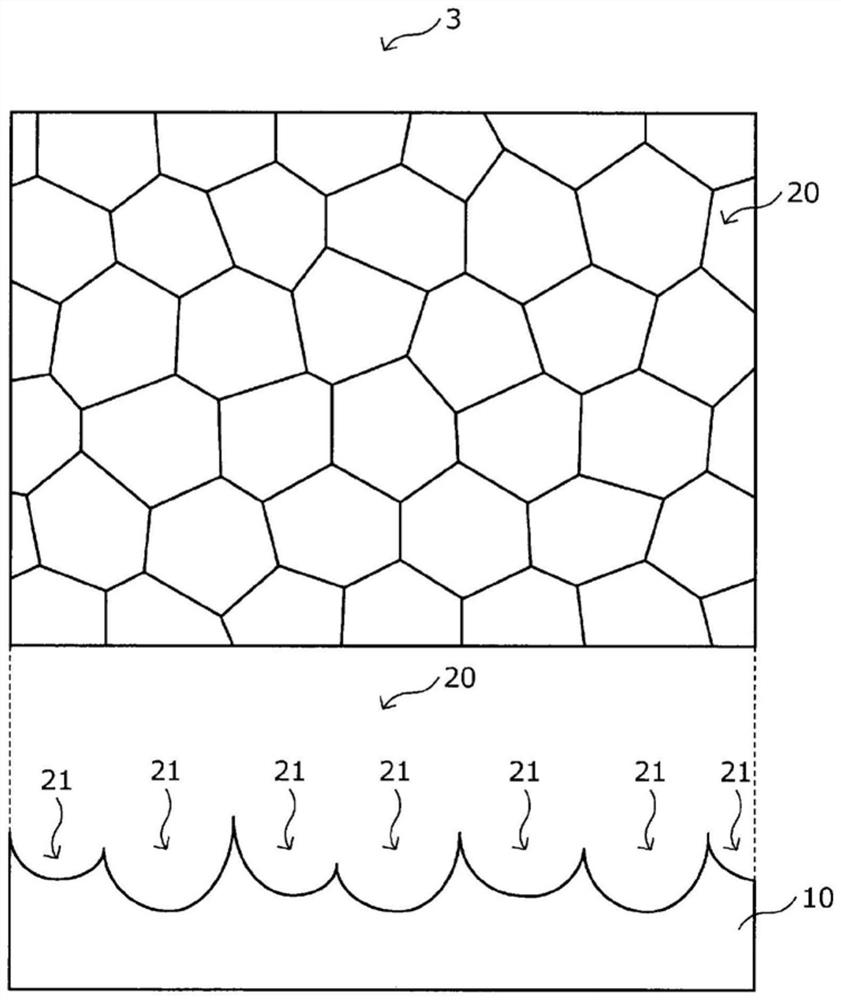

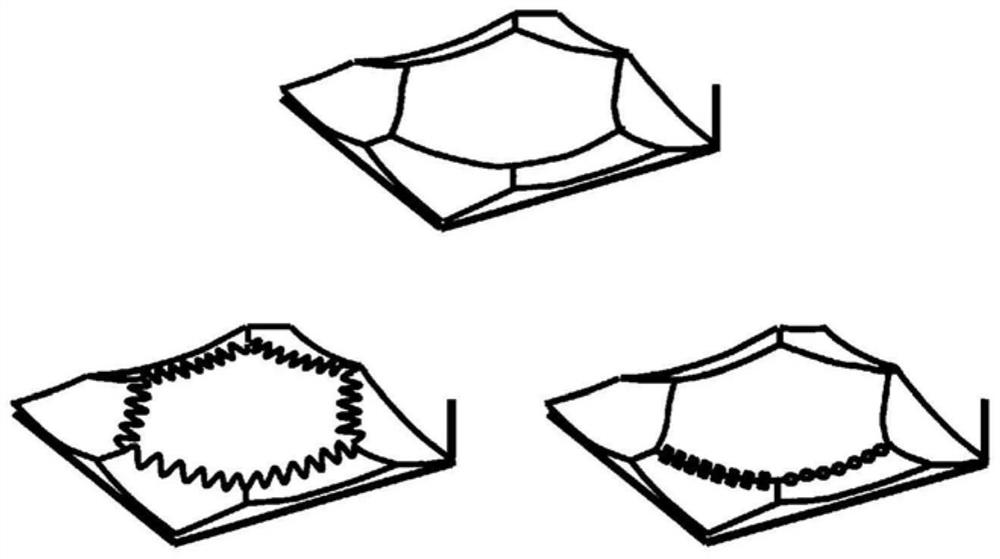

[0076] figure 2 It is an explanatory diagram schematically showing a part of unit cells constituting the diffuser plate according to the present embodiment. Figure 3A ~ Figure 4B It is an explanatory diagram showing an example of the boundary state between adjacent microlenses in the unit cell according to this embodiment. Figure 5 It is an explanatory diagram schematically showing the diffuser plate according to this embodiment. Figure 6A ~ Figure 7B It is an explanatory diagram for explaining the arrangement of unit cells in the diffuser plate according to the present embodiment.

[0077] The diffusion plate 1 according to the present...

no. 2 approach

[0160] As a diffuser for highly coherent light such as laser light, various diffusers having a full angle of diffusion of about 1 degree to 30 degrees are used. For example, in the application of uniformly diffusing the incident laser light with a phosphor surface, a diffusion plate with a full diffusion angle of less than 10 degrees is used, and in the application of obtaining the same diffusion characteristics as the phosphor film by using blue light, and in the application of reducing speckle Then use a diffusion plate with a full diffusion angle of about 10 degrees to 30 degrees. When using a microlens type diffuser plate to realize a diffuser plate having a relatively large full angle of diffusion of 10 degrees to 30 degrees, there is a problem that the attenuation of diffused light is not so sharp in the angle region where the intensity of diffused light is attenuated. .

[0161] Therefore, when realizing a diffuser plate applicable to the above-mentioned application us...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| refractive index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com