A method to improve the permeability of silk single-sided digital inkjet printing

A digital inkjet and digital printing technology, which is applied in printing, dyeing, printing devices, etc., can solve problems affecting high-end positioning, whitening, and light colors, and achieve the effects of breaking through technical bottlenecks, improving permeability, and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The above is only a specific embodiment of the present invention, but the scope of protection of the present invention is not limited thereto. Anyone skilled in the art can easily think of changes or substitutions within the technical scope disclosed in the present invention. Should be covered within the protection scope of the present invention. Therefore, the protection scope of the present invention should be determined by the protection scope of the claims.

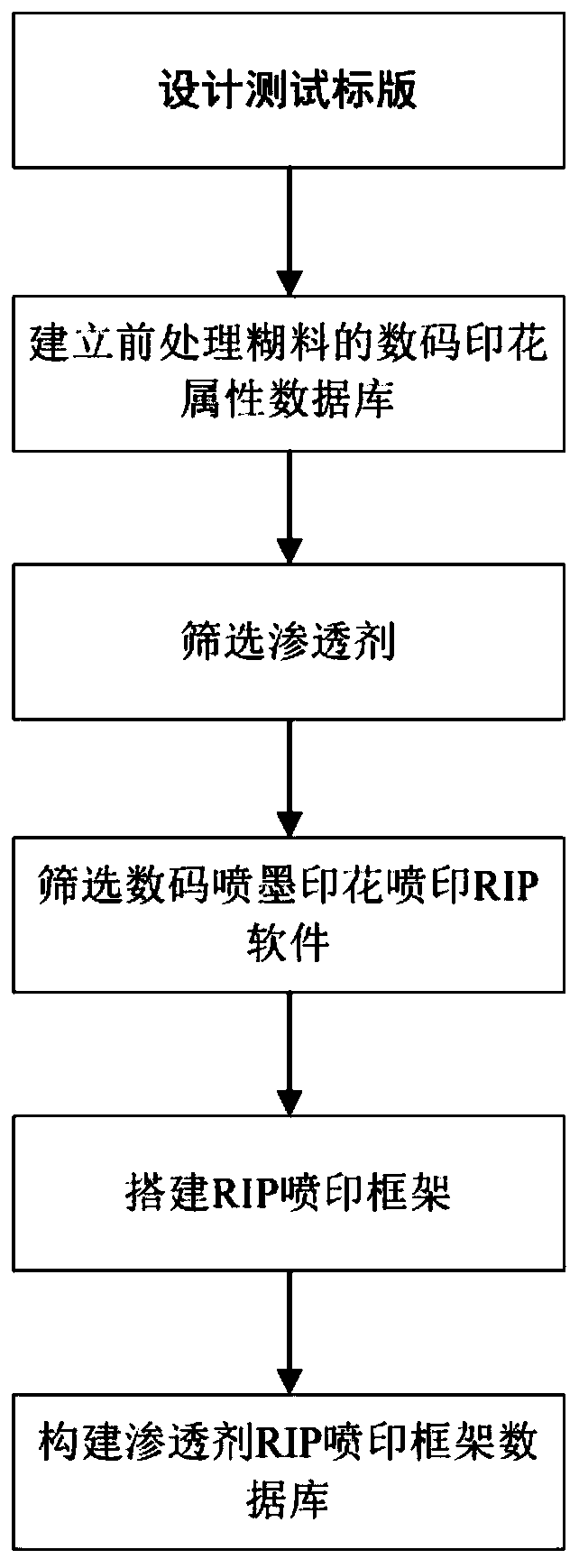

[0027] Such as figure 1 As shown, the invention provides a method for improving the permeability of silk digital inkjet printing, the method may further comprise the steps:

[0028] Step 1. Design test standard plate:

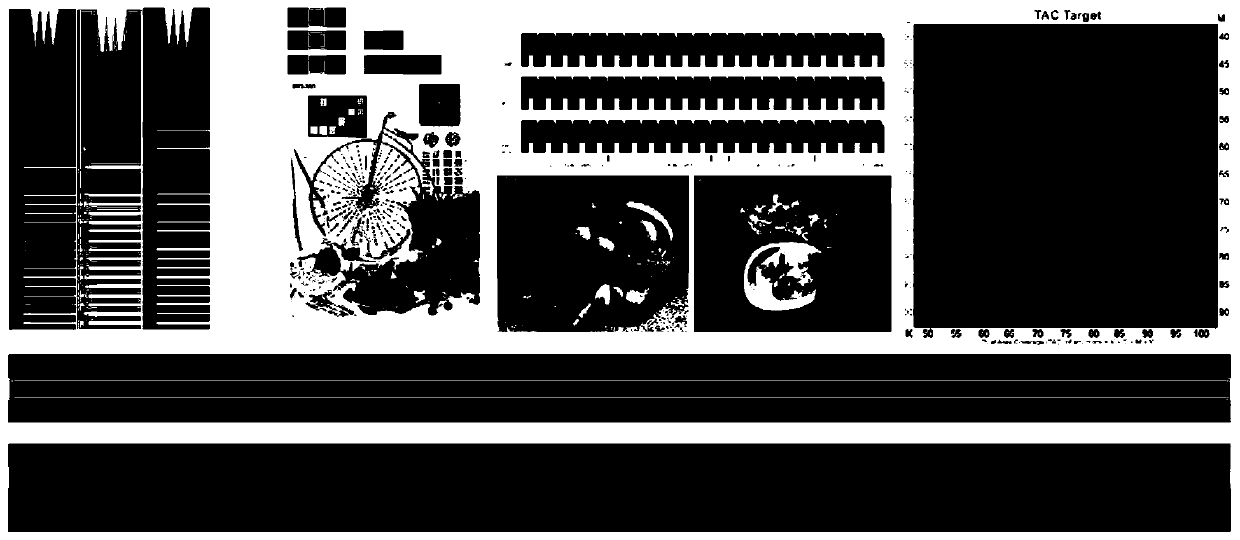

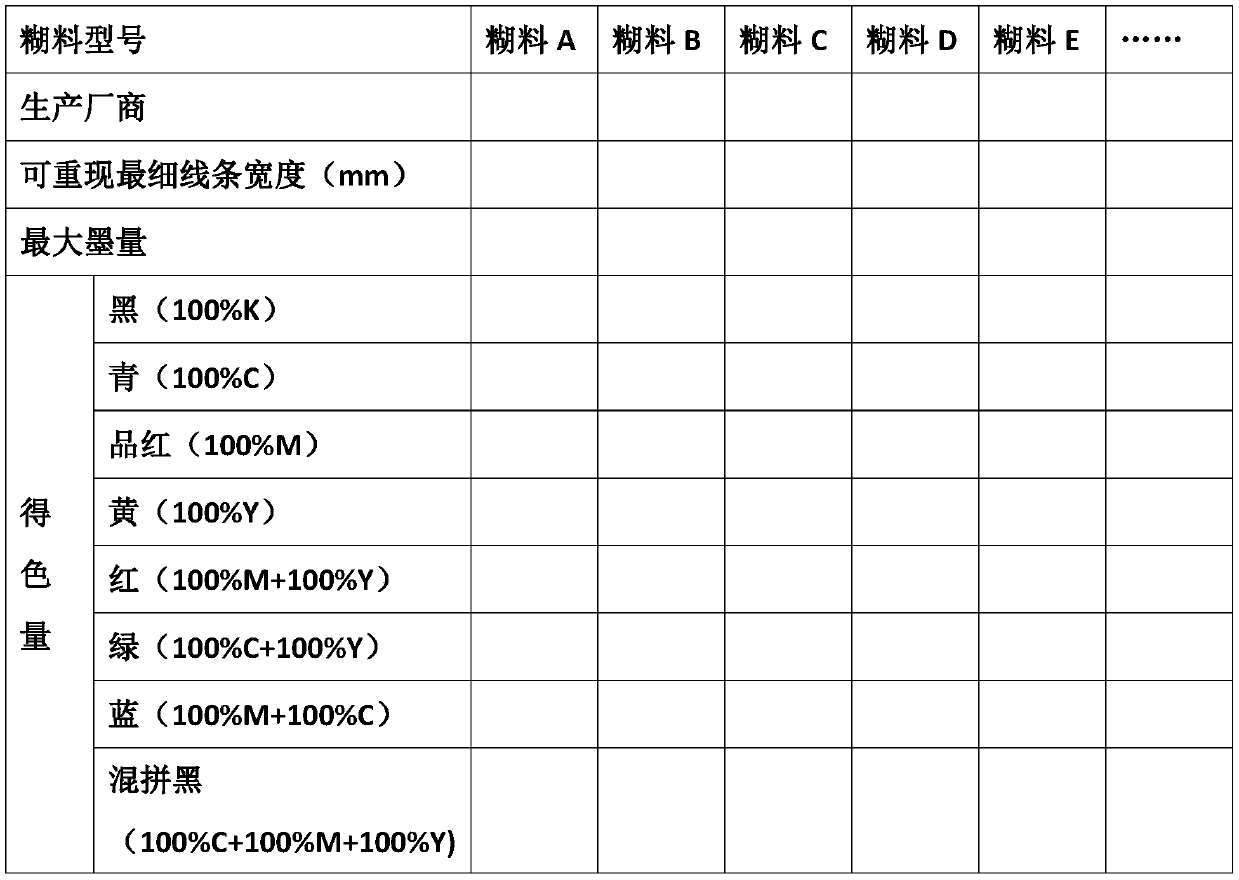

[0029] The test standard is as figure 2 As shown, the test standard plate is designed for the properties of textile digital printing, and the test elements include: fineness unit, color yield unit, maximum ink unit, permeability unit and pattern subjective effect unit, used to Test the fin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com