Medical capsule production process

A production process and capsule technology, which is applied in capsule transportation, pharmaceutical formulations, progressive dryers, etc., can solve the problems of high labor intensity, incoherent capsule filling, high cost, etc., achieve good drying effect and save time , the effect of reducing waste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further elaborated below in conjunction with specific embodiments.

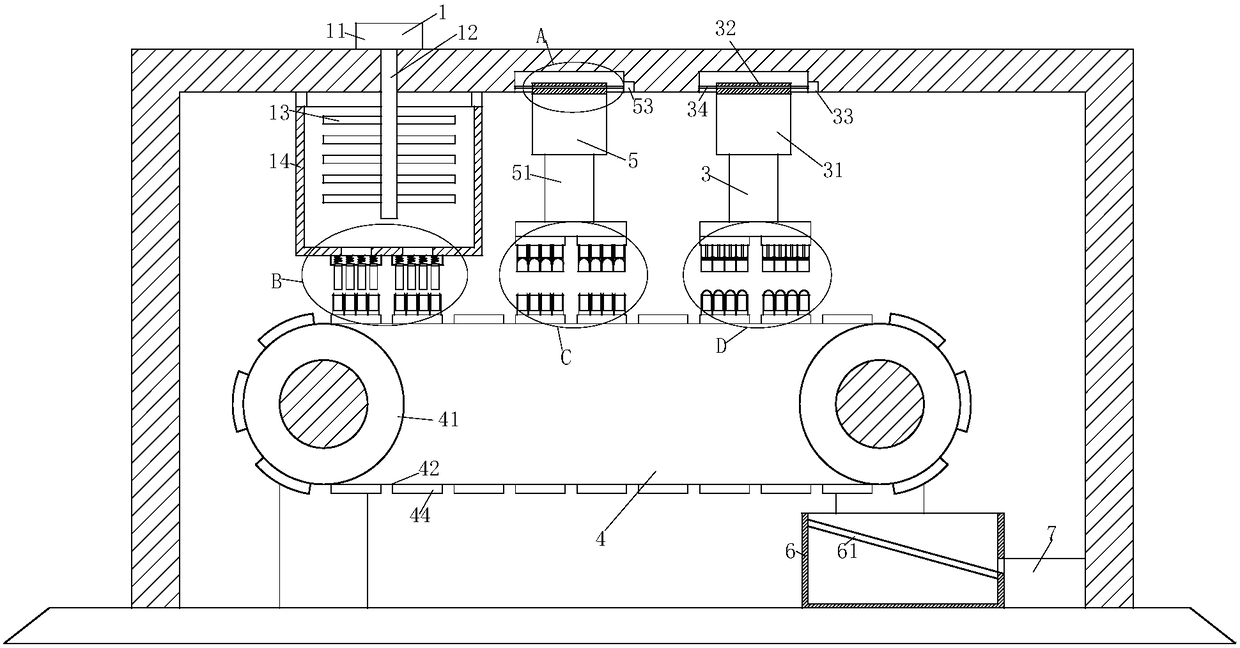

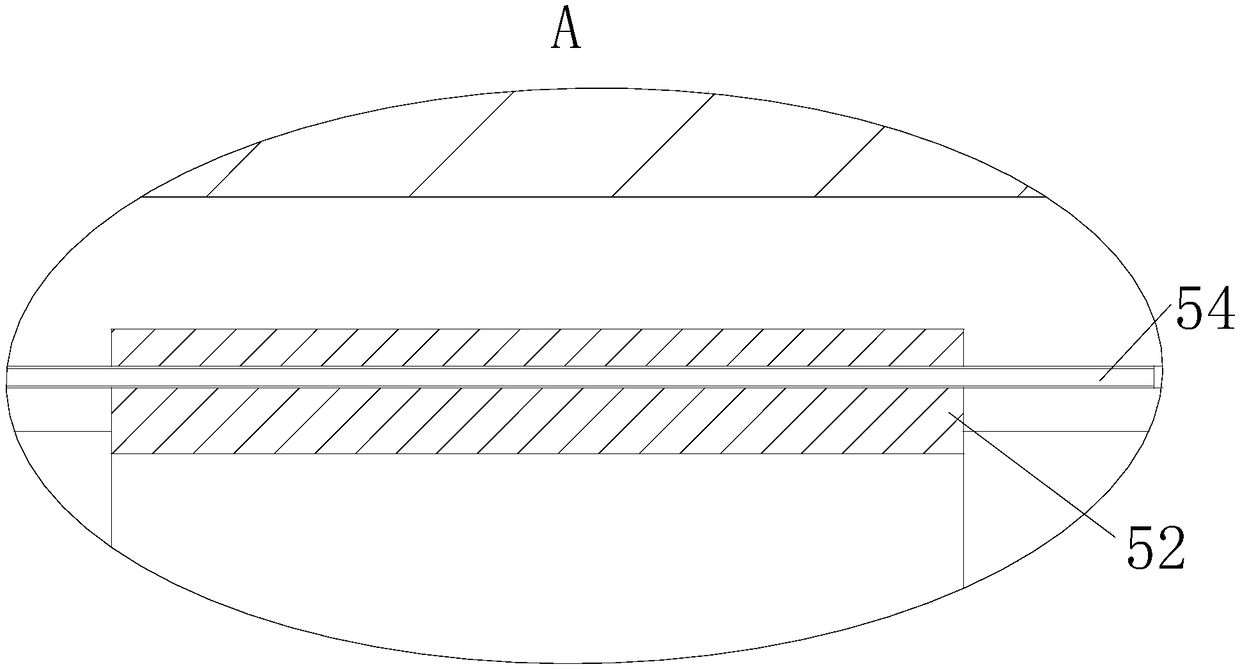

[0034] Such as Figure 1 to Figure 6 As shown, a kind of medical capsule production technique of the present invention, this technique adopts capsule filling device, wherein capsule filling device comprises stirring module 1, filling module 2, drying module 3, transmission module 4, capsule sealing module 5, charging Basket 6 and packaging machine 7, the stirring module 1 is installed on the support frame, and the stirring module 1 is used to stir the medicine; the filling module 2 is installed under the stirring module 1, and the filling module 2 is used to fill the medicine into the capsule Middle; the transmission module 4 is located below the filling module 2, the transmission module 4 is intermittent transmission, and the transmission module...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com