Original position-type nonpowered modularization slurry separator and slurry separating method thereof

A mud-water separation and power module technology, which is used in mud-water separation devices, on-site dehydration of engineering high-moisture mud, and mud-water separation. The problem of high power consumption and high energy consumption can achieve the effect of low cost of use, convenient installation and disassembly, and improved effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

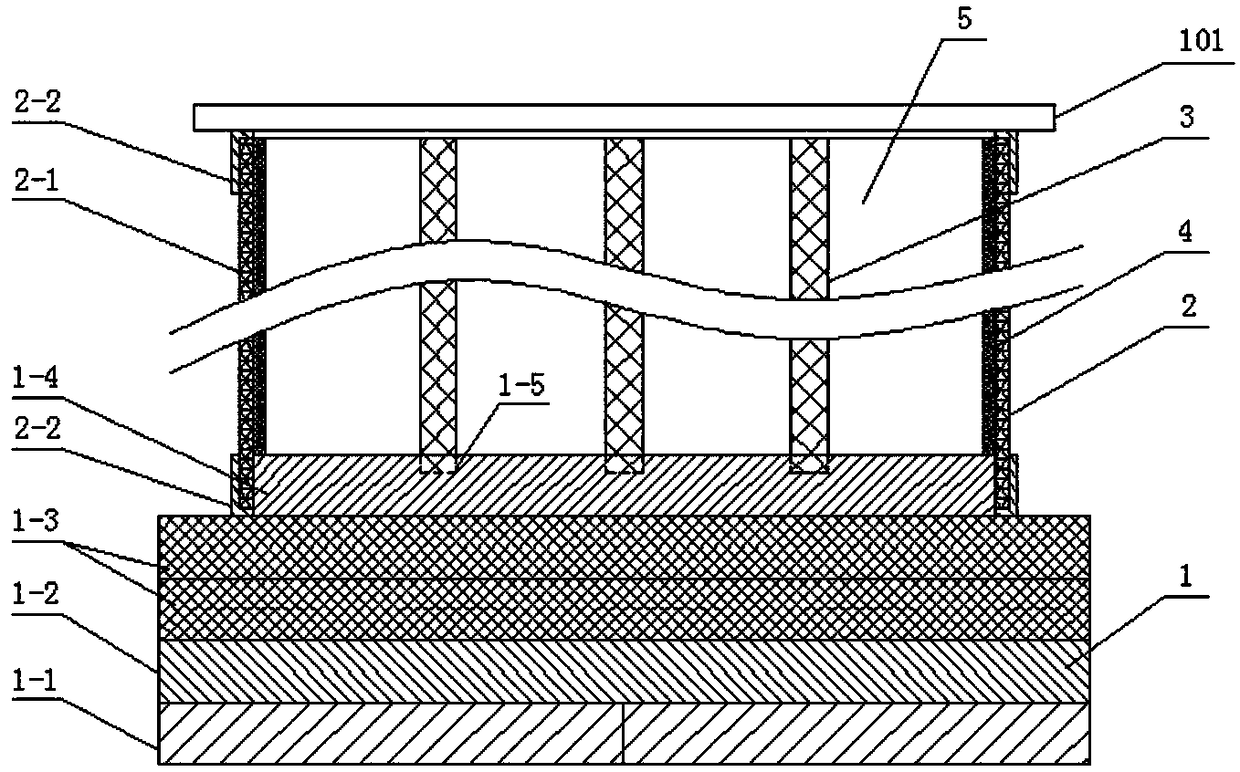

[0020] Below in conjunction with accompanying drawing, the present invention is further described;

[0021] The invention is an in-situ non-powered modular mud-water separation device.

[0022] The so-called in-situ: that is where the sludge can be dewatered. This not only solves the problem of no storage yard (storage capacity) for dredging sludge, but also greatly eases the pressure on sludge transportation.

[0023] The so-called powerless: that is, the device does not need electric energy and other power during the whole processing process.

[0024] The so-called modularization: that is, each part of the whole device is independently formed, self-contained, and has its own functions. When used, it is like building blocks and combined according to needs.

[0025] In the attached picture:

[0026] The in-situ non-powered modular mud-water separation device includes a load-bearing infiltration module 1 at the bottom, a support module 2 connected to the load-bearing infiltr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com