Preparation method of alkali excitation enhanced sulphoaluminate cement based material

A sulfoaluminate cement, reinforced technology, applied in the field of building materials, can solve problems such as excessive heat of hydration, strength shrinkage, etc., and achieve the effects of reducing economic costs, high early strength, and improving development speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

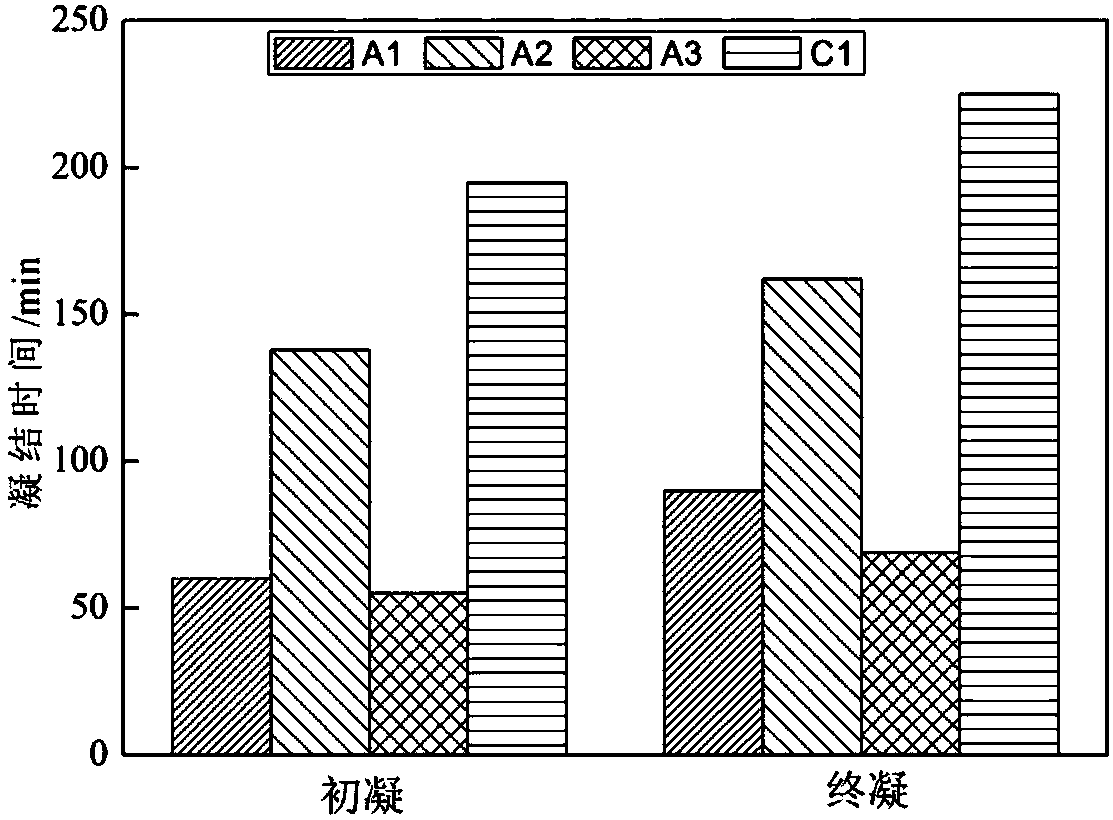

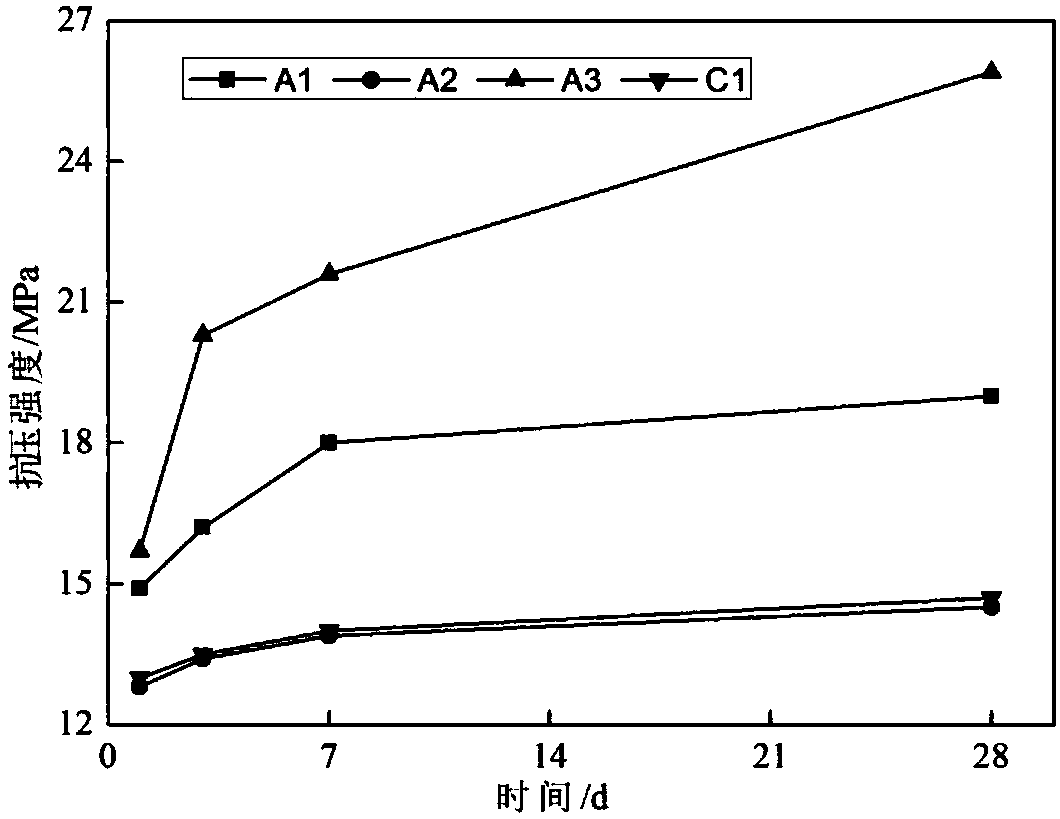

Embodiment 1

[0024] Preparation of alkali-activated reinforced sulphoaluminate cement

[0025] (1) 480g sulfoaluminate cement is mixed with 120g fly ash cementitious material;

[0026] (2) the calcium hydroxide of 3g is dissolved in 360g water and is mixed with calcium hydroxide aqueous solution;

[0027] (3) Add the cementitious material to the calcium hydroxide aqueous solution and place it on a cement slurry mixer and stir slowly for four minutes.

Embodiment 2

[0029] Preparation of alkali-activated reinforced sulphoaluminate cement

[0030] (1) 450g sulfoaluminate cement and 150g fly ash account for cementitious material to mix;

[0031] (2) the calcium hydroxide of 6g is dissolved in 360g water and is mixed with calcium hydroxide aqueous solution;

[0032] (3) Add the cementitious material to the calcium hydroxide aqueous solution and place it on a cement slurry mixer and stir slowly for four minutes.

Embodiment 3

[0034] Preparation of alkali-activated reinforced sulphoaluminate cement

[0035] (1) 510g sulfoaluminate cement and 90g fly ash account for cementitious material to mix;

[0036] (2) the calcium hydroxide of 12g is dissolved in 360g water and is mixed with calcium hydroxide aqueous solution;

[0037] (3) Add the cementitious material to the calcium hydroxide aqueous solution and place it on a cement slurry mixer and stir slowly for four minutes.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Compressive strength | aaaaa | aaaaa |

| Compressive strength | aaaaa | aaaaa |

| Compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com