Sinomenine hydrochloride and preparation method thereof

A technology of sinomenine hydrochloride and centrifugal extractor, which is applied in the direction of organic chemistry, can solve the problems of serious extraction emulsification, difficulty in two-phase separation, and low extraction production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

experiment example 1

[0024] 1. Description of the original extraction process (mixed and clarified)

[0025] Process method

[0026] Pump the liquid to be extracted (volume V) into the extraction tank, extract twice with chloroform as follows, and combine the extracts.

[0027] The first extraction: pump 1 / 2 times the amount of chloroform into the extraction tank, and start the extraction tank stirrer to stir for 30 minutes. After 30 minutes, stop stirring, let the layers stand for more than 1 hour, and slowly put the lower chloroform layer into the extract storage tank. After putting the layered chloroform, stir it 3 times, then let the layers stand for more than 1 hour, and then slowly put the lower layer of chloroform into the extract storage tank. Repeat the above inching stirring, standing and layering methods, so that the extraction yield meets the requirements (extraction yield = the amount of the extracted extract / the amount of chloroform fed, the requirement is ≥ 80.0%).

[0028] The s...

experiment example 2

[0085] Experimental Example 2: Experimental Research Data

[0086] 1. Purpose of the experiment

[0087] In order to solve the problems of emulsification, difficult stratification and small processing capacity in the current mixing and clarification extraction process, after preliminary experiments, the centrifugal extraction machine can use centrifugal method to quickly and effectively break the emulsion and separate, solve the problem, and realize continuous production. In order to confirm the feasibility of the centrifugal extraction process and determine the extraction and separation conditions of the centrifugal extraction machine, an extraction experiment was carried out.

[0088] 2. Experimental method

[0089] (1) Process design

[0090] Basic process: take Qingfengteng percolation alkalization solution (take Qingfengteng, use 0.3mol / L hydrochloric acid solution as solvent, wet, impregnate, percolate, add calcium hydroxide to the percolation liquid to adjust the pH v...

Embodiment 1

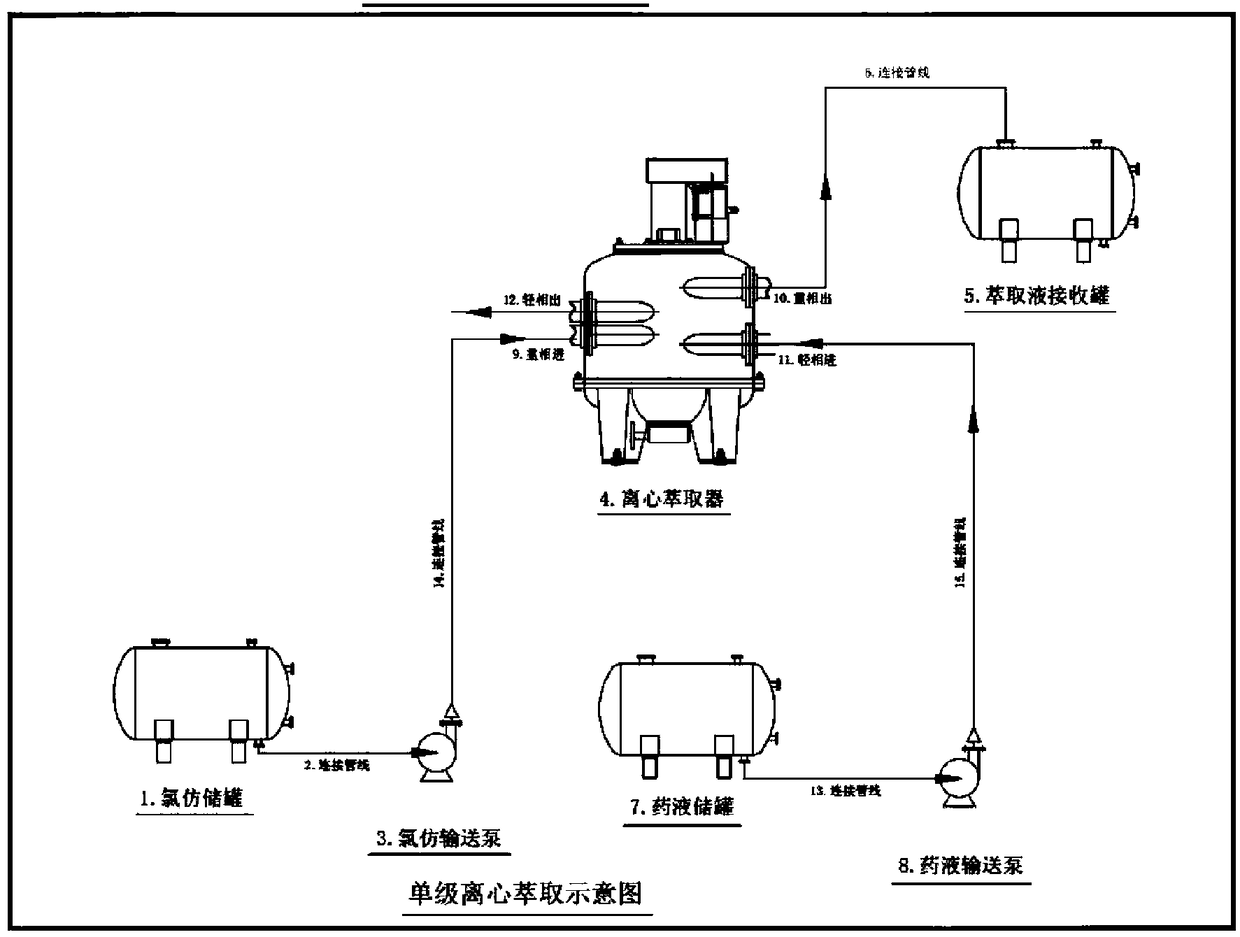

[0149] Embodiment 1: Single-stage extraction prepares sinomenine hydrochloride

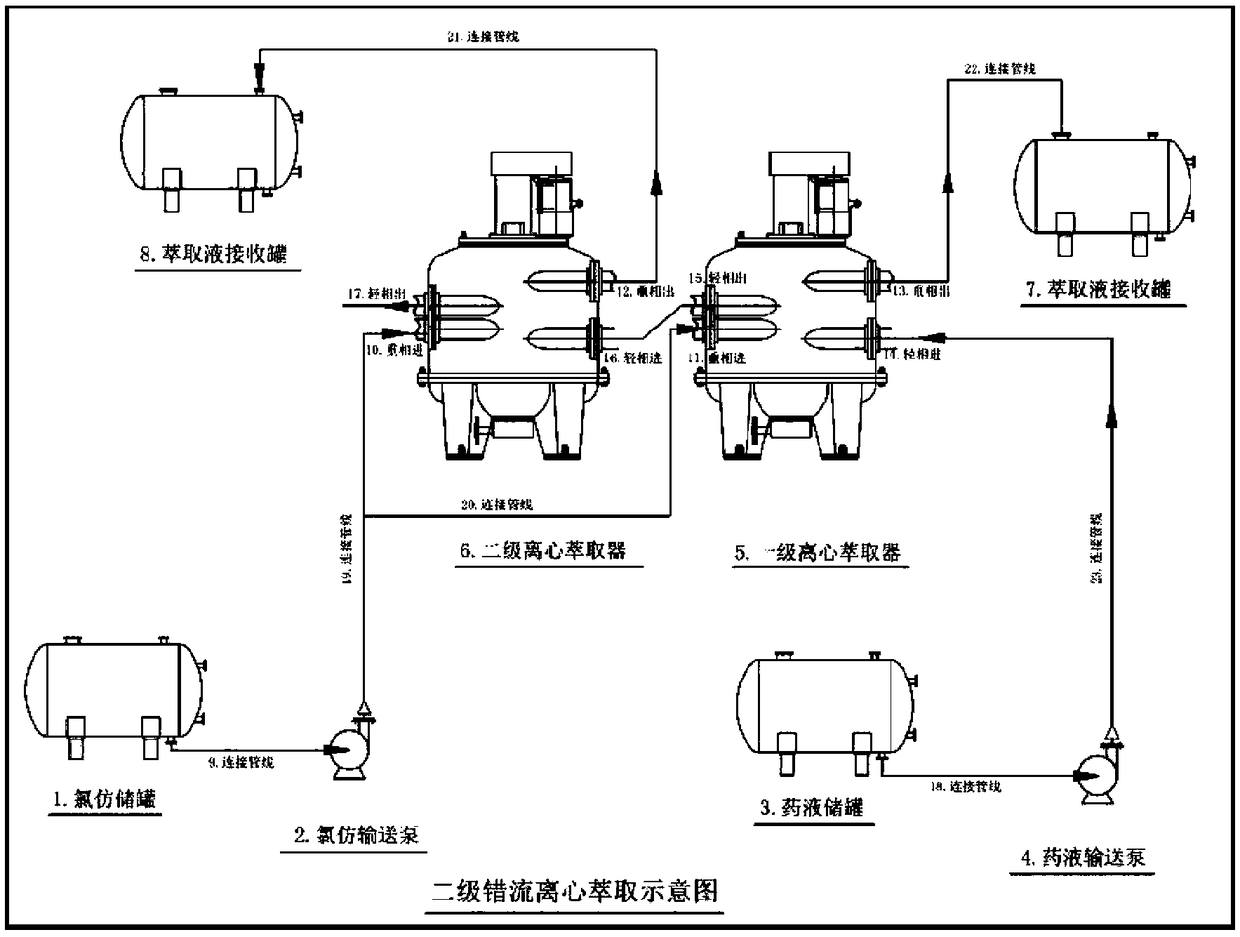

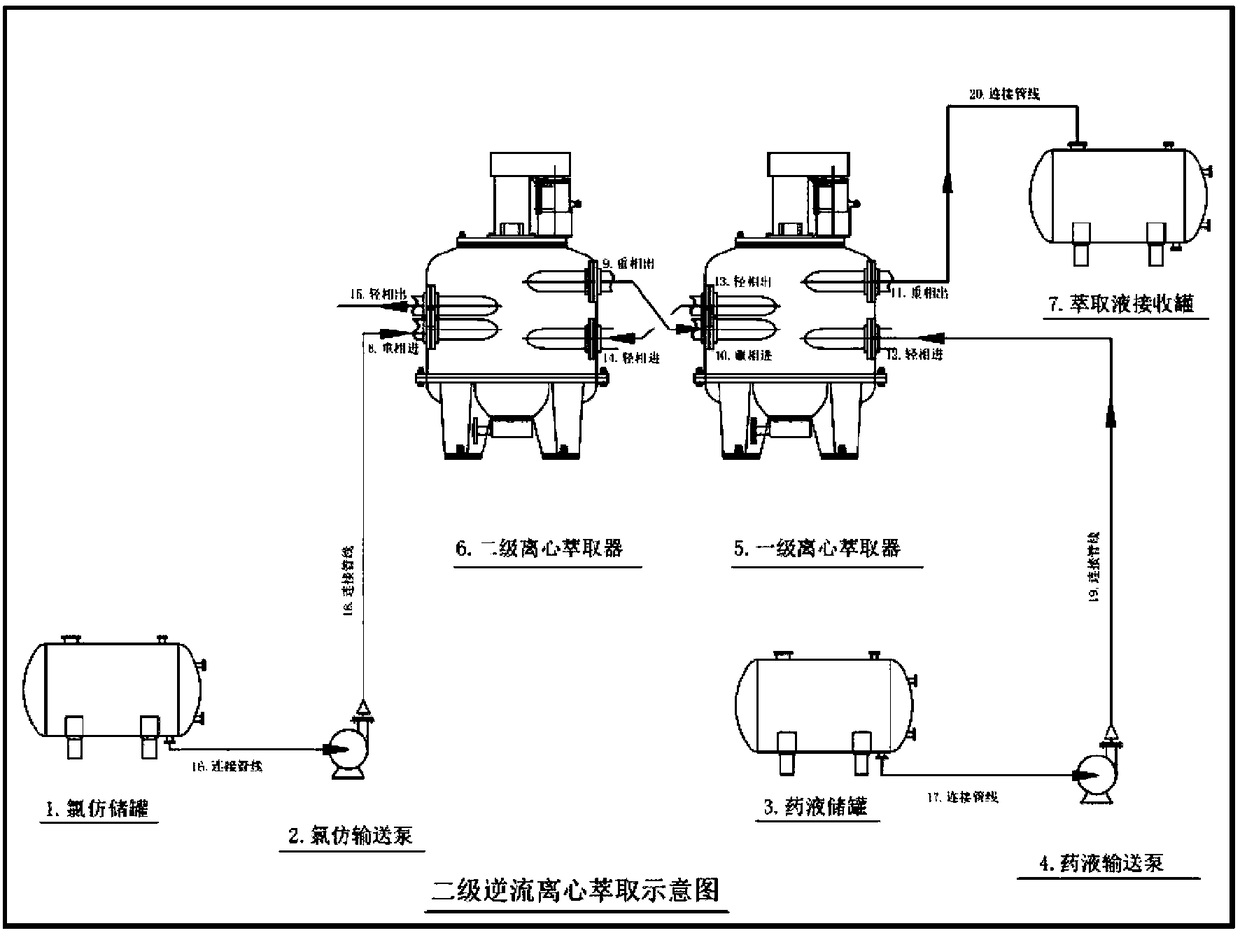

[0150] Extract with a single centrifugal extractor, turn on the drum motor of the centrifugal extractor, and extract the liquid medicine at a rate of 10,000 liters / hour; connect two extraction centrifuges, turn on the drum motor of the centrifugal extractor, and extract the liquid medicine at a rate of 10,000 liters / hour The speed is pumped in from the light phase inlet of the first-stage centrifugal extractor, and then flows through the second-stage centrifugal extractor; the extraction agent chloroform is pumped in from the heavy-phase inlet of the second-stage centrifugal extractor at a speed of 7500 liters / hour, and then flows through the first-stage centrifugal extractor. Centrifugal extractor to collect the extract.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com