Knitting machine electromagnetic needle selection machine drive plate and knitting machine electromagnetic needle selection machine

A knitting machine and needle selector technology, which is applied in the directions of knitting, weft knitting, textile and paper making, etc., can solve the problems of low integration, inconvenient installation time, low safety of electricity consumption, etc. Installation, small footprint effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

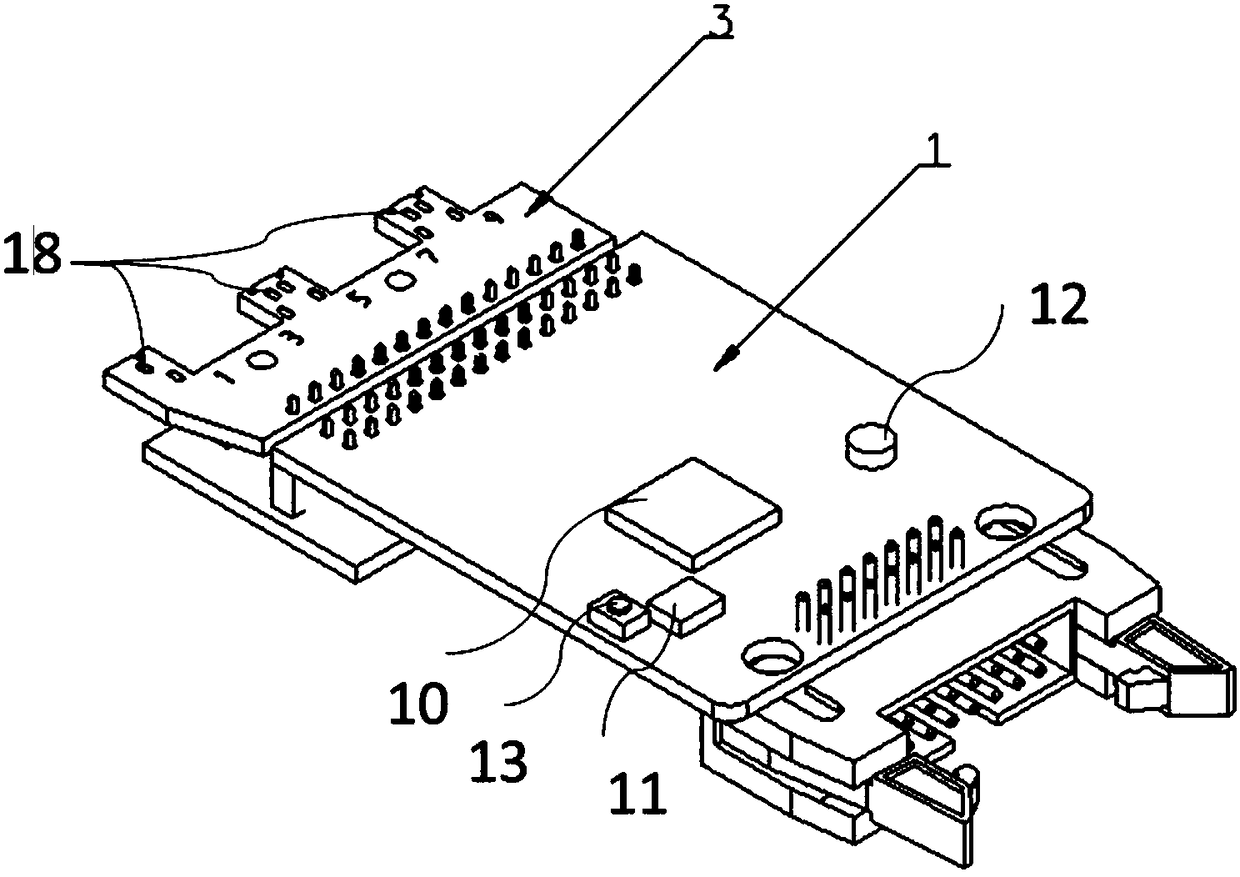

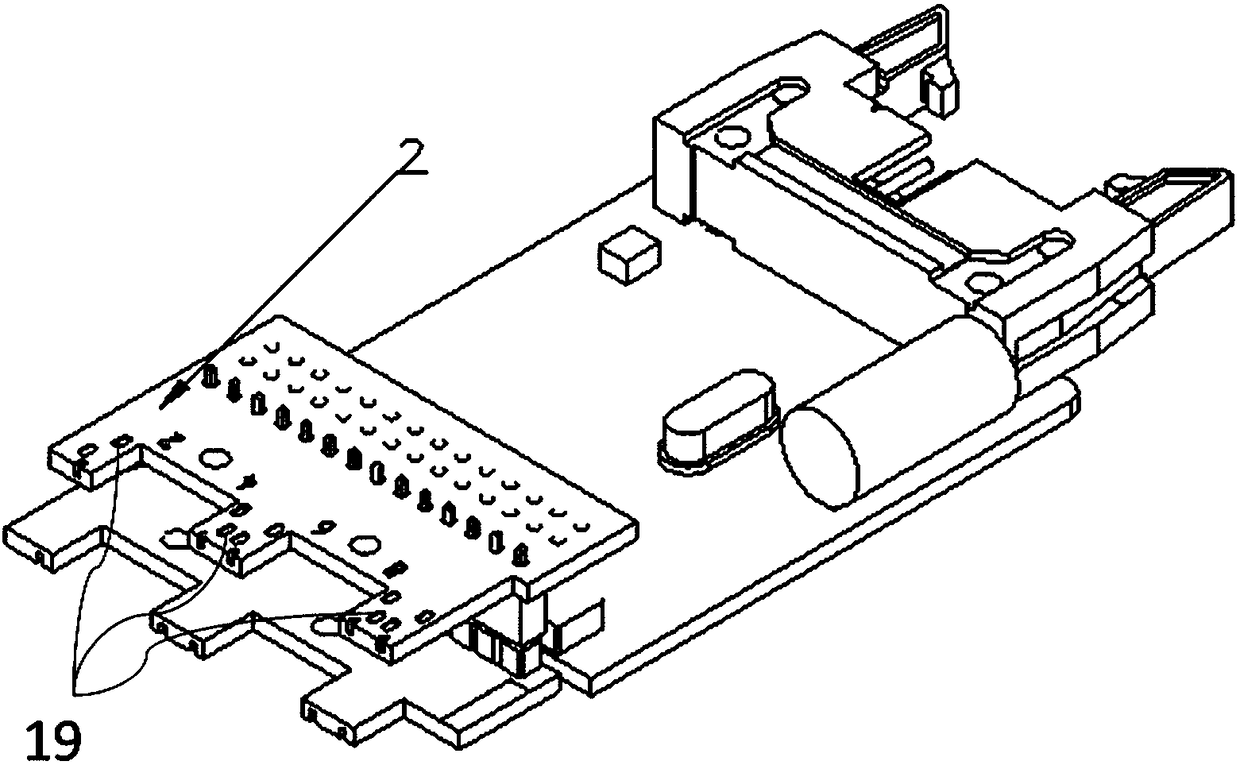

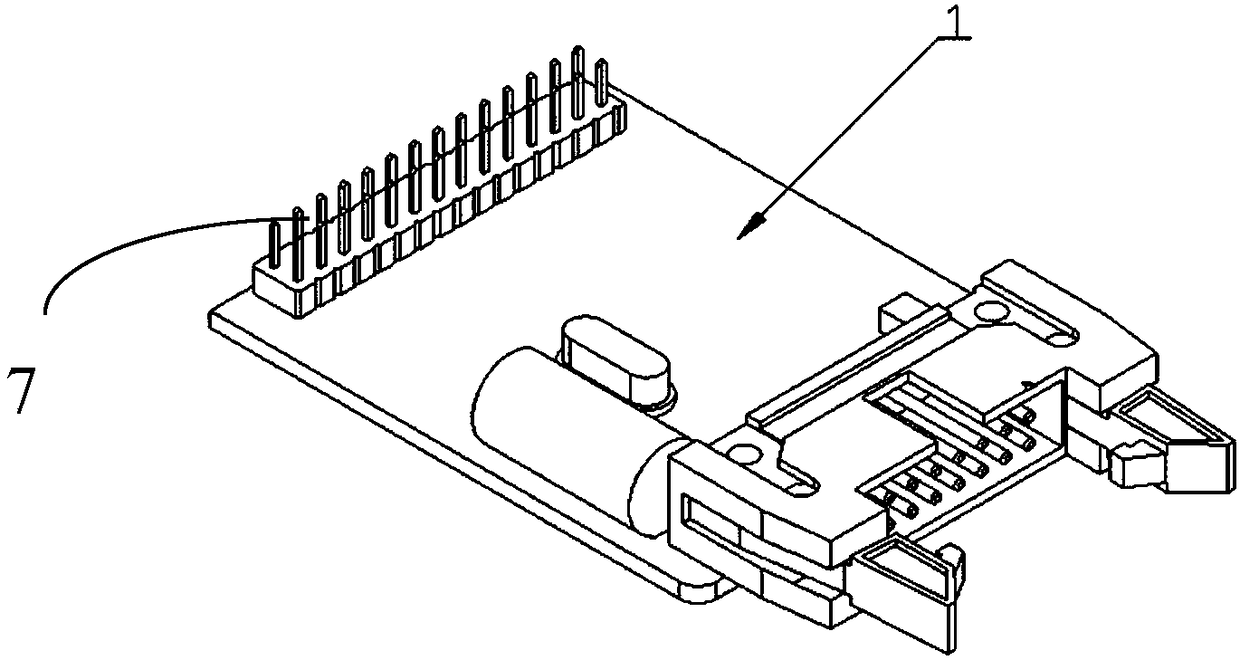

[0025] The specific implementation manners of the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments. The following examples are used to illustrate the present invention, but are not intended to limit the scope of the present invention.

[0026] The inventor has tried to change the serial number of the electromagnetic needle selector by means of binary address dialing, but this method needs to be manually changed on the driving board of the electromagnetic needle selector of the knitting machine, which is easy to dial wrongly or not in place, and the electromagnetic needle selector on the knitting machine The installation interval between the devices is small, the binary address dial module and other modules on the driving board of the electromagnetic needle selector of the knitting machine are close to each other, the dial space is very limited, and the dial operation is easily hindered, while the electroma...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com