Rock drilling tool

A drilling tool and rock formation technology, which is applied to drilling tool accessories, drill bits, twist drills, etc., can solve the problems of increasing the frictional resistance of drilling holes and reducing the volume of chip removal grooves for output drilling cuttings, so as to improve the conveying performance and reduce the The effect of friction loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

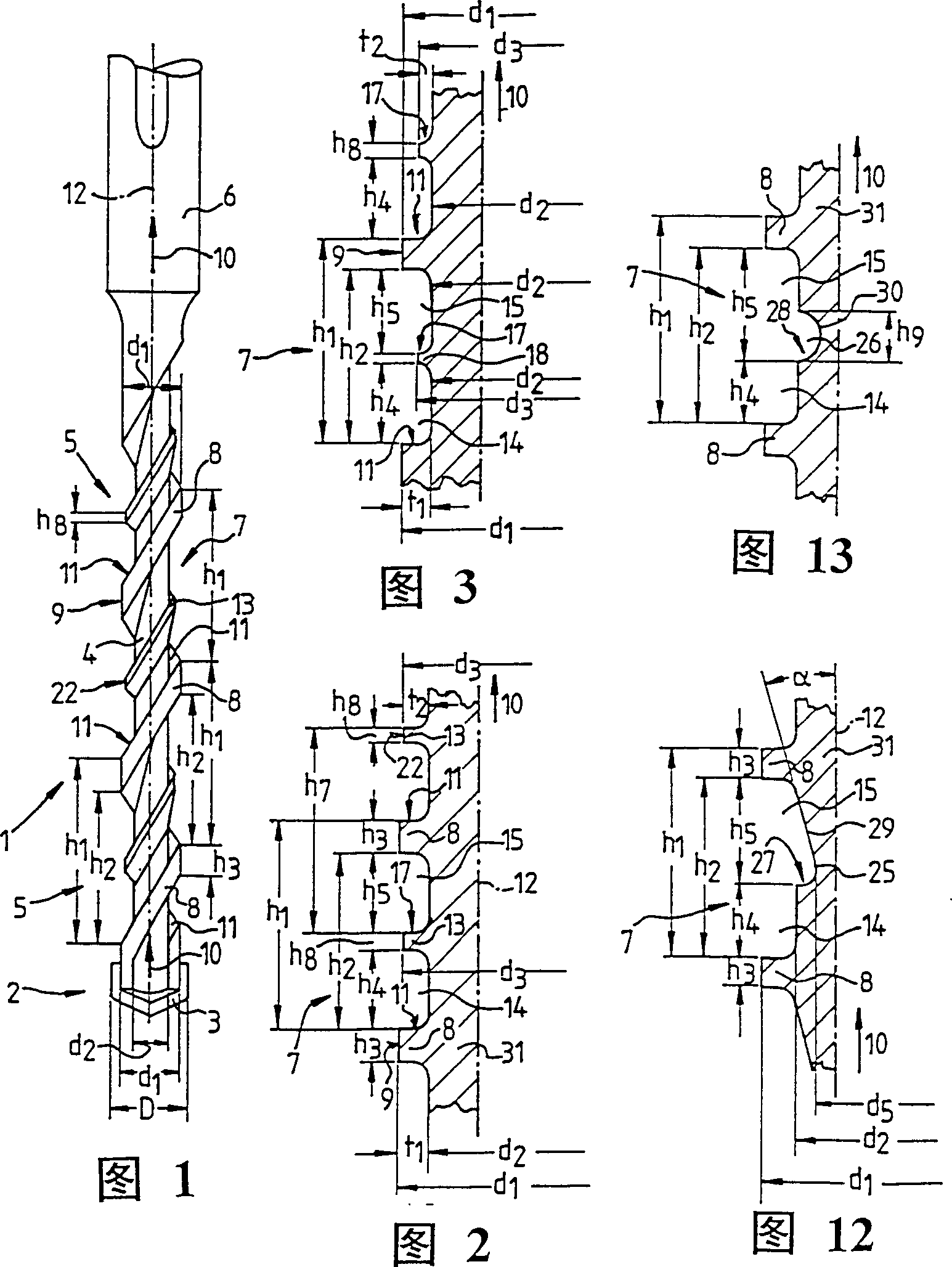

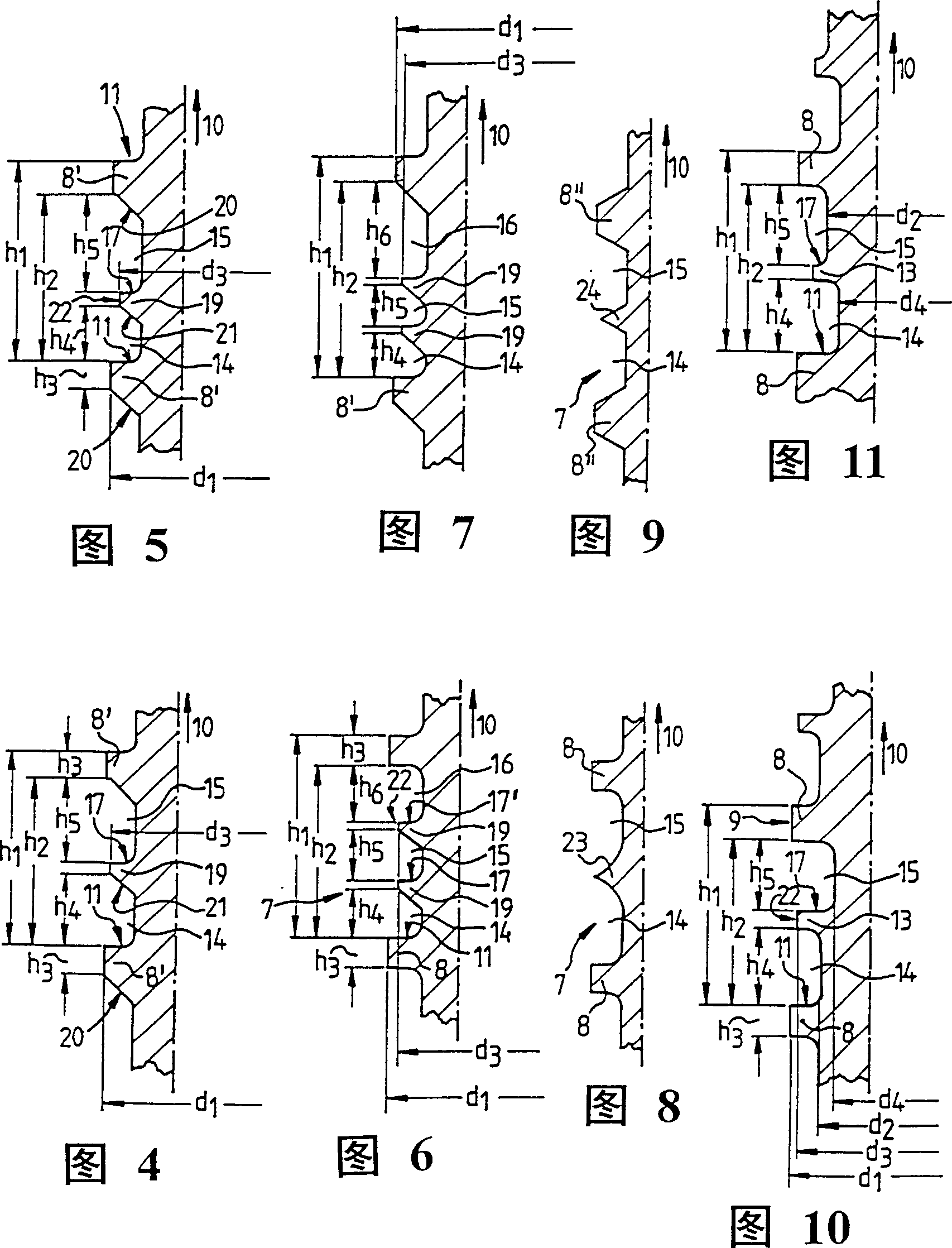

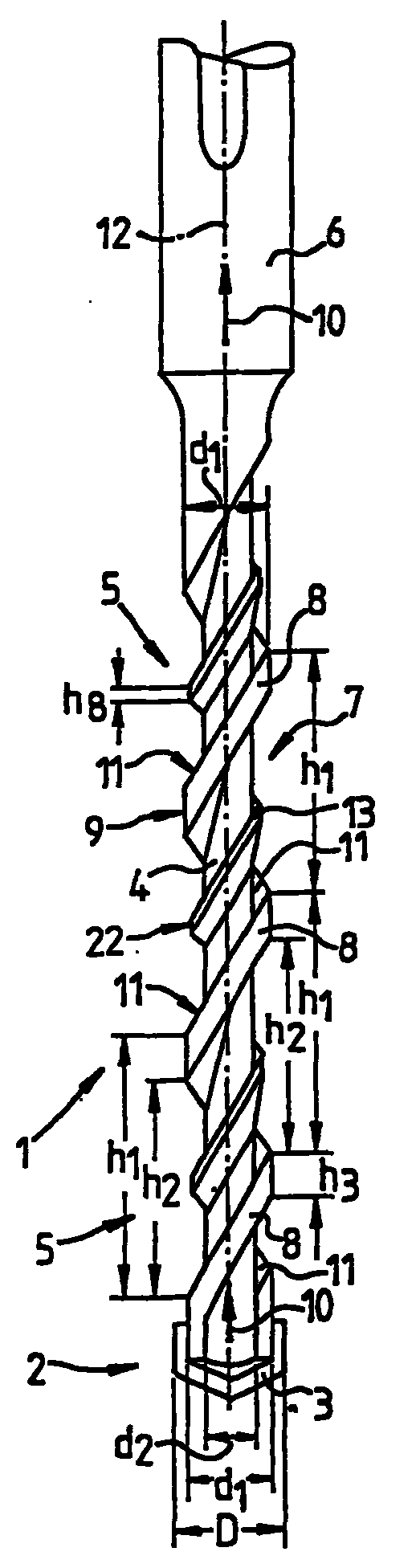

[0017] The exemplary embodiment shown in FIG. 1 constitutes the basic form of the invention. Here, the basic inventive principle of arranging primary ribs and secondary ribs is implemented in such a way that several individual chip flute sections are formed in an existing chip flute 7, said individual sections forming Their own additional cuttings conveying surface. Embodiments that vary from this basic type are shown in FIGS. 2 to 13 .

[0018] The rock formation drilling tool 1 shown in Fig. 1 comprises a drill bit 2, and it is preferably arranged on a carbide cutting blade 3 of end portion; A screw rod 4, it has a delivery screw 5; Clamping rod 6 for inserting the drill into a drive mechanism.

[0019] In the exemplary embodiment shown in Figure 1, the screw conveying rod has a pitch height of h 1 The single-head spiral, which forms a helical flute 7 around, and its height is h 2 , its two sides are surrounded by the same helically extended ribs 8 . rib height h 3 The...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com