A kind of preparation method of nanoscale supported molybdenum sulfide catalyst

A nano-scale, catalyst technology, applied in the direction of catalyst activation/preparation, physical/chemical process catalyst, molybdenum sulfide, etc., can solve the problem of reducing surface energy, improving the degree of dispersion and suspension, and unfavorable active sites with many stacked layers of nanosheets Exposure and other issues to achieve the effect of avoiding self-agglomeration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

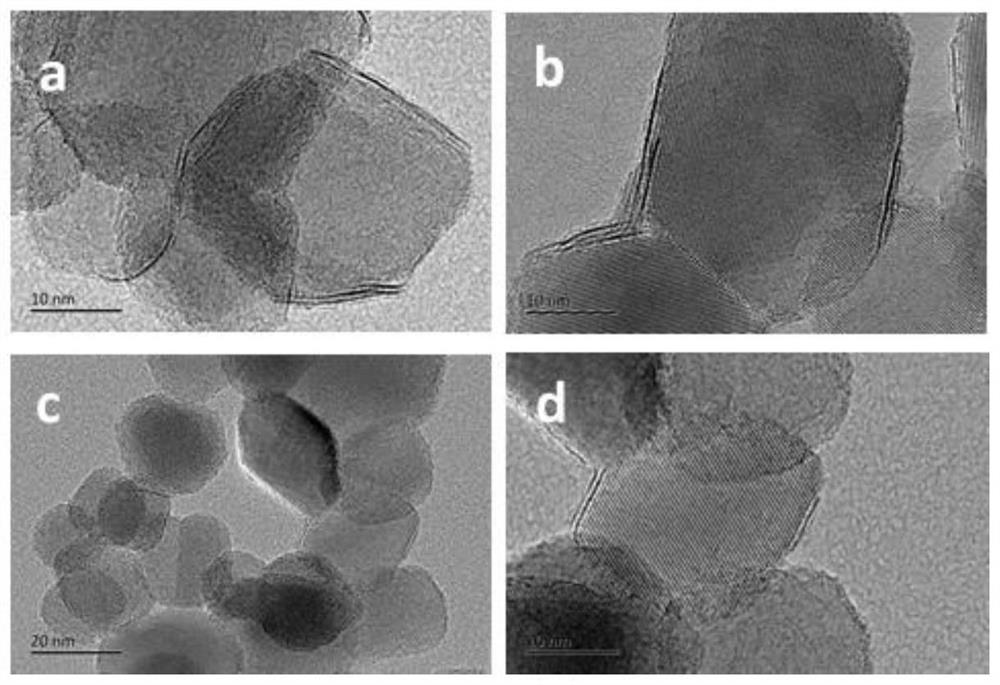

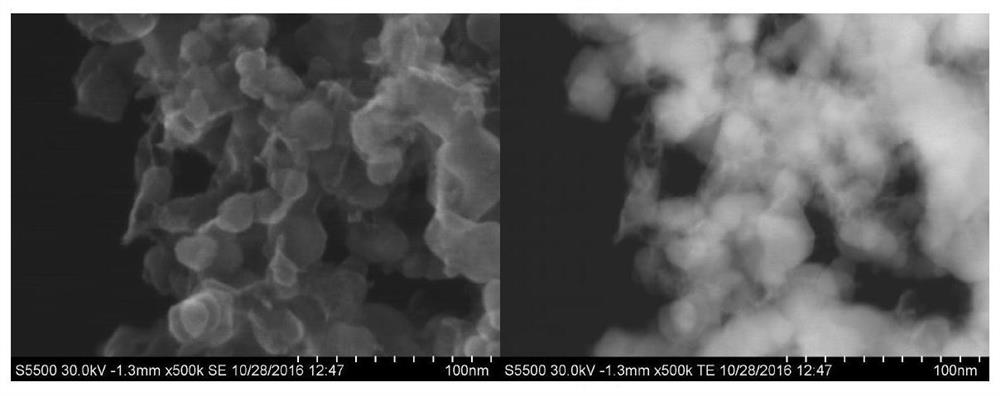

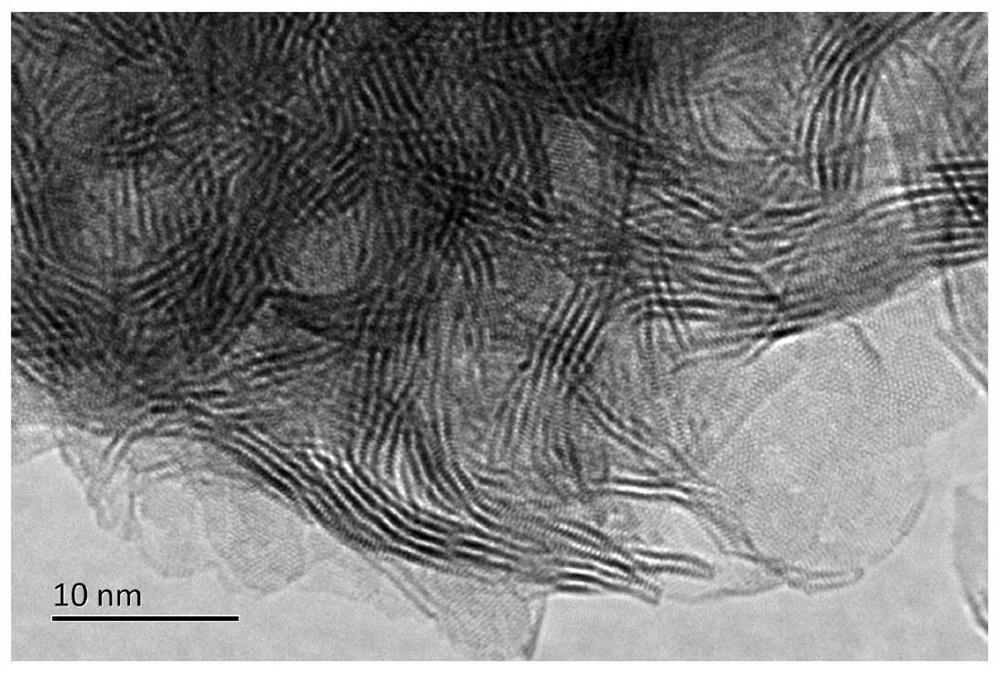

[0026] Disperse 7.5 mmol of commercial titanium oxide carrier in 60 ml of deionized water, and stir ultrasonically to form a suspension evenly. Dissolve 0.16mmol of ammonium molybdate and 3.48mmol of ammonium sulfide in the suspension and stir evenly so that the Mo / Ti molar ratio is 0.15. Then add 6.72mmol of hydrazine hydrate reducing agent to make Mo / reducing agent 1:6. After fully stirring, the suspension was transferred to a 100ml hydrothermal kettle, reacted at 180°C for 12h, cooled naturally to room temperature, filtered with suction, washed with deionized water and absolute ethanol, dried under vacuum at 70°C overnight, and collected nano Grade Loaded MoS 2 sample. The samples were characterized by HRTEM. HRTEM results showed that the prepared MoS2 was nanosheets with stacked layers of 2-3 layers and a sheet length of 10-20nm. The carrier used was highly dispersed nanoparticles figure 1 a).

Embodiment 2

[0028] Disperse 7.5 mmol of self-made titanium oxide carrier in 60 ml of deionized water, and stir ultrasonically to form a suspension evenly. Dissolve 2.24mmol of molybdenum oxide and 6.96mmol of sodium sulfide in the suspension and stir evenly to make the Mo / Ti molar ratio 0.3. Then add 6.72mmol of hydrazine hydrate reducing agent to make Mo / reducing agent 1:3. After fully stirring, the suspension was transferred to a 100ml hydrothermal kettle, reacted at 160°C for 24h, cooled naturally to room temperature, filtered with suction, washed with deionized water and absolute ethanol, dried under vacuum at 70°C overnight, and collected nano Grade Loaded MoS 2 sample. The samples were characterized by HRTEM. The HRTEM results showed that the prepared MoS2 was nanosheets with 2-3 stacked layers and a sheet length of 10-15nm. The carrier used was highly dispersed nanoparticles 2 The small size and low packing load maximize the exposure of its catalytic active side (see figure 1 b)...

Embodiment 3

[0030] Disperse 7.5 mmol of commercial titanium oxide carrier in 60 ml of deionized water, and stir ultrasonically to form a suspension evenly. Dissolve 0.11 mmol of ammonium tetrathiomolybdate in the suspension and stir evenly so that the Mo / Ti molar ratio is 0.015. Then add 0.66mmol of hydrazine hydrate reducing agent to make Mo / reducing agent 1:6. After fully stirring, transfer the suspension to a 100ml hydrothermal kettle, react at 200°C for 6h, cool to room temperature naturally, filter with suction, wash the precipitate with deionized water and absolute ethanol, dry it under vacuum at 70°C overnight, and collect nano Grade Loaded MoS 2 sample. The samples were characterized by HRTEM, and the HRTEM results showed that the prepared MoS 2 It is a nanosheet with a stacked layer number of 1-2 layers and a sheet length of 5-10nm. The carrier used is a highly dispersed nanoparticle of 2 The small size and low packing load maximize the exposure of its catalytic active side (s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com