Automatic caisson sinking device and construction method

A technology of caisson and work frame, which is applied in the direction of caisson, infrastructure engineering, construction, etc., to achieve the effects of strong soil adaptability, timely and easy deviation correction, and high construction efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

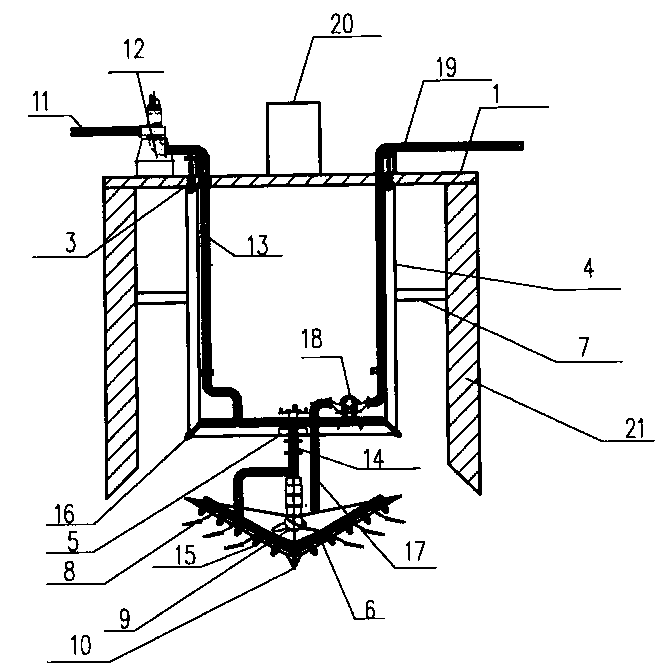

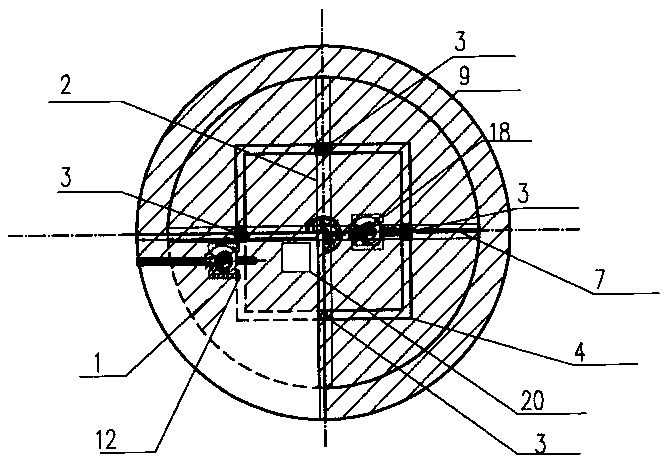

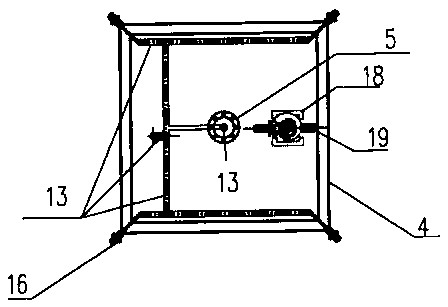

[0036] The caisson automatic sinking device in this embodiment uses the high-pressure water nozzle 15 to wash the soil and the submersible electric mud cutting blade 8 to cut the soil together to convert the undisturbed soil inside the caisson into mud, and through the rotation of the lower working frame 6 To expand the scope of soil cutting, the submersible mixer 9 rotates to mix the mud and water evenly, and the sludge pump 18 pumps it away from the working face, and the sludge output pipe 19 transports it to the outside of the well;

[0037] In this embodiment, the sinking height and deviation correction of the caisson are realized by the automatic control of each electrical equipment after the control system analyzes the collected caisson elevation and caisson inclination data.

[0038] The operating range of the lower working frame in this embodiment is adjusted by the adjustable screw at the upper end of the vertical connecting frame. When the sinking speed of the caisson...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com