Roof greening construction process method

A construction technology and roof greening technology, which is applied to building roofs, roof drainage, roof insulation materials, etc., can solve the problems of roof waterproof layer damage, roof surface corrosion, etc., and achieve the effect of reducing corrosion and increasing load

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

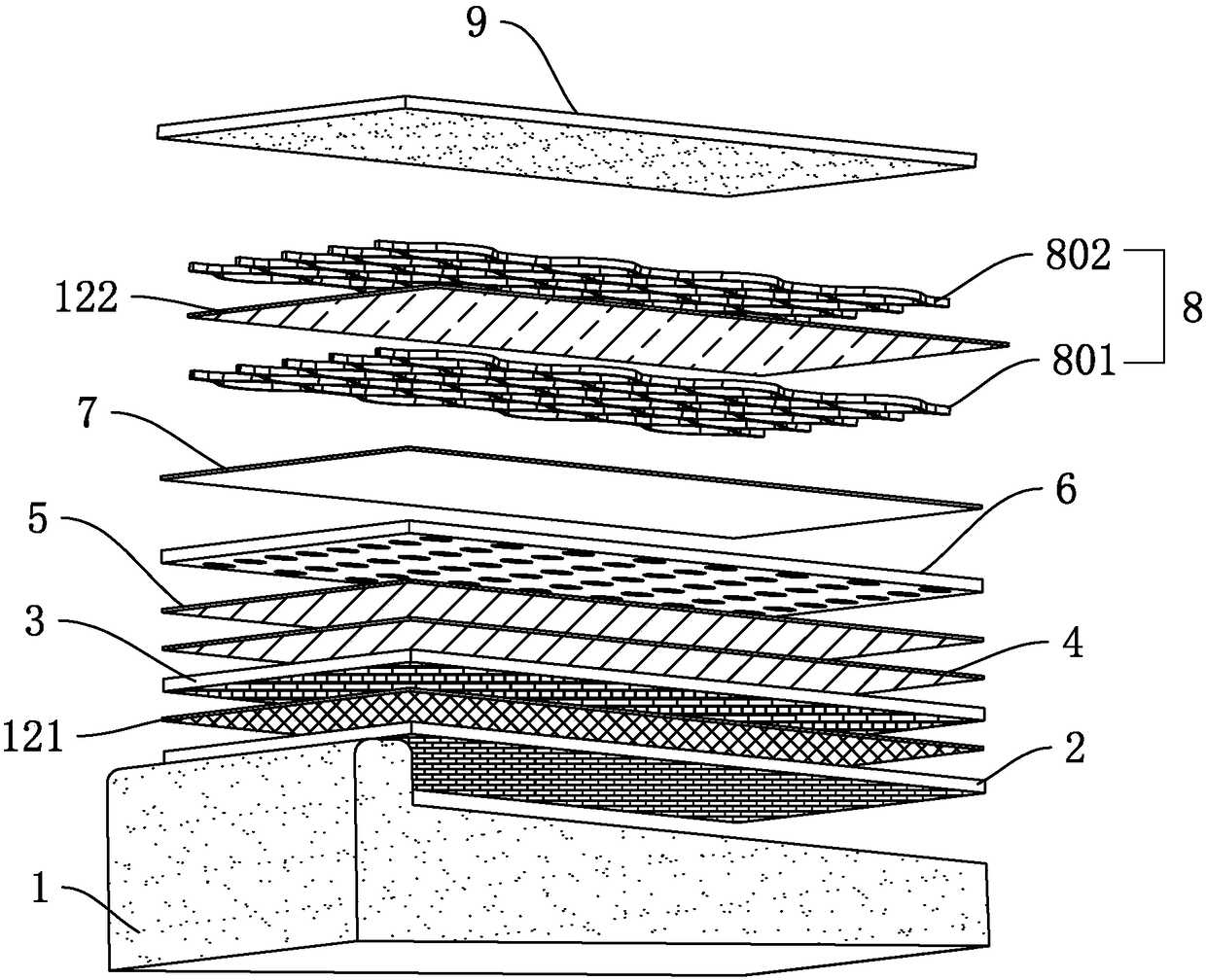

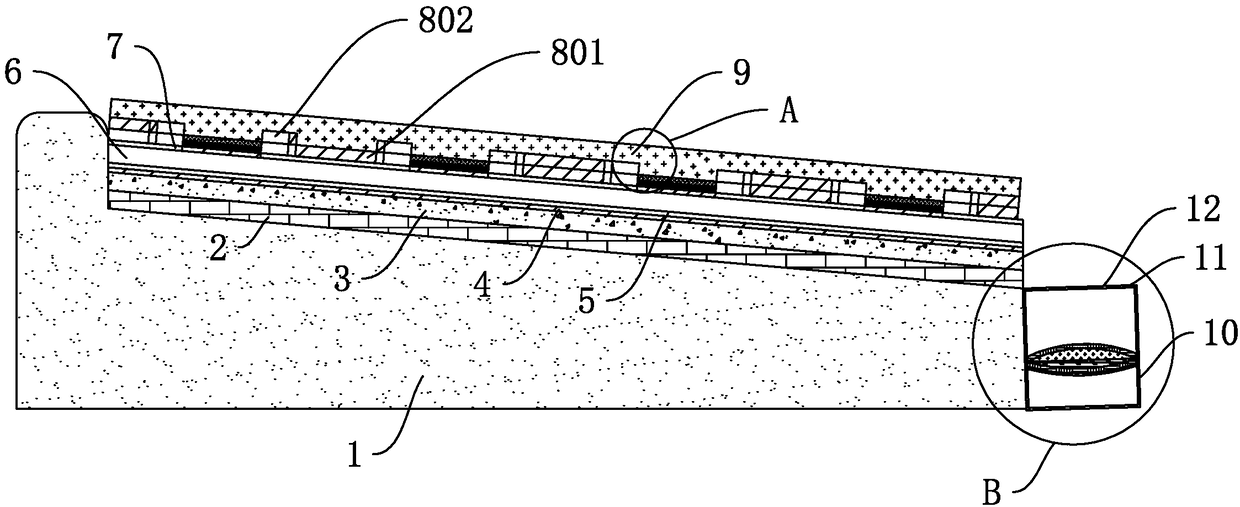

[0041] Embodiment: a kind of roof greening construction technique method, as figure 2 As shown, the method flow is as follows: (a), manually measure the slope of the surface of the roof base structure 1, and lay the foam glass plate 2 on the position with a high slope first, and then along the direction of the slope from high to low, on the roof base The structure 1 is covered with foam glass plates 2, and a certain drainage slope is formed on the surface of the laid foam glass plates 2;

[0042] (b), combined figure 1 As shown, the mesh 121 is laid on the foam glass plate 2, and the mesh 121 is made of stainless steel metal mesh 121, and then the lightweight concrete is poured on the foam glass plate 2, and it is maintained for three days. After the surface of the light concrete is completely cured, Form a concrete protective layer 3 with a thickness of 5 cm;

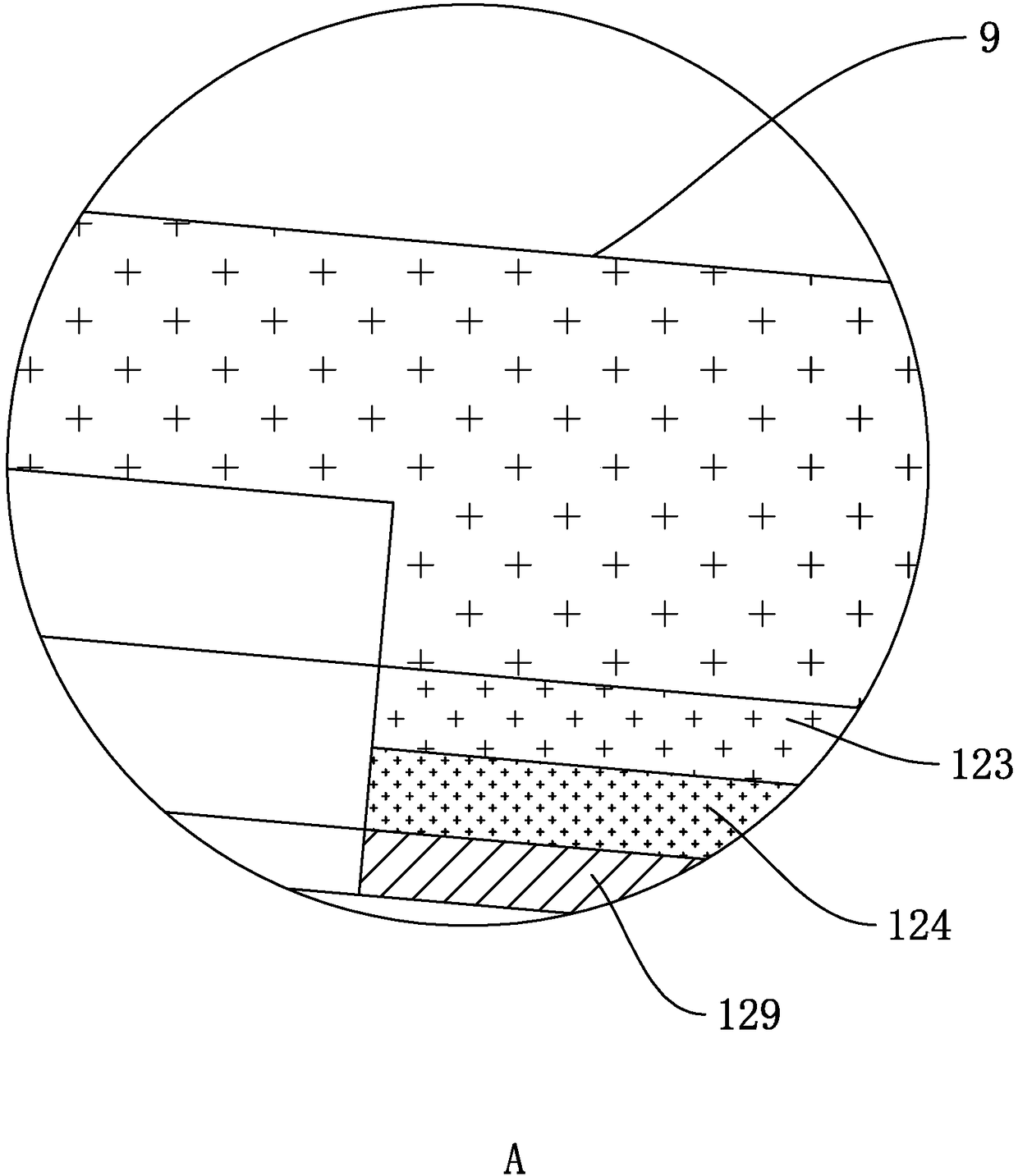

[0043] (c), if figure 1 As shown, the surface of the concrete protection layer 3 is cleaned, and then the first ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com