A planetary gear transmission

A technology of planetary gear transmission and planetary gear, applied in the direction of gear transmission, transmission, transmission parts, etc., can solve the problems of inconvenient daily observation and maintenance, large passenger capacity, etc., and achieve the elimination of adverse effects and no impact on the structure , the effect of simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

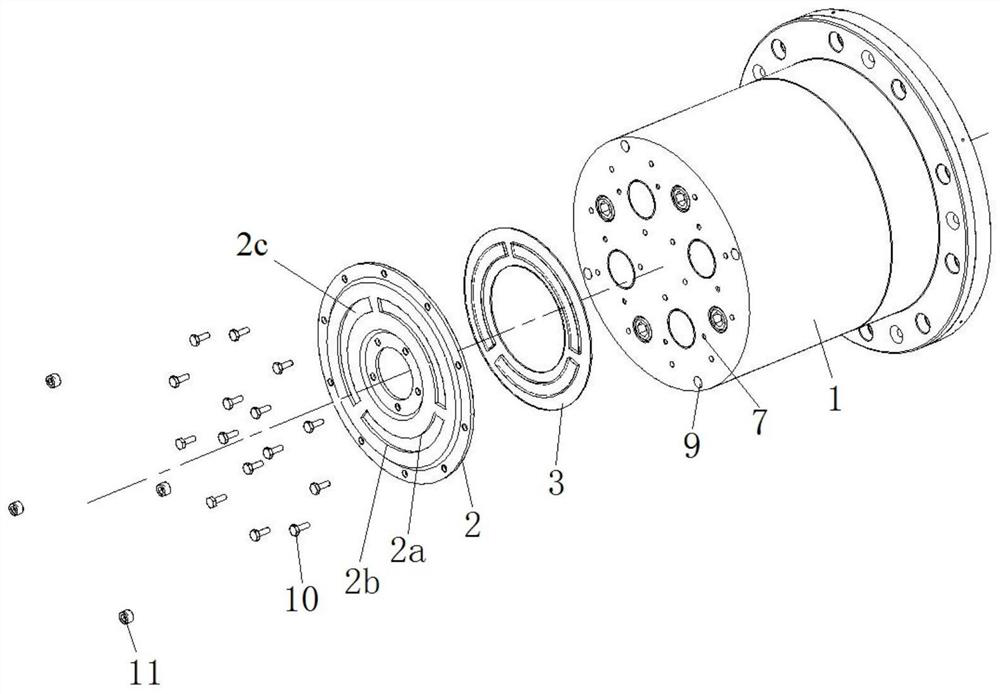

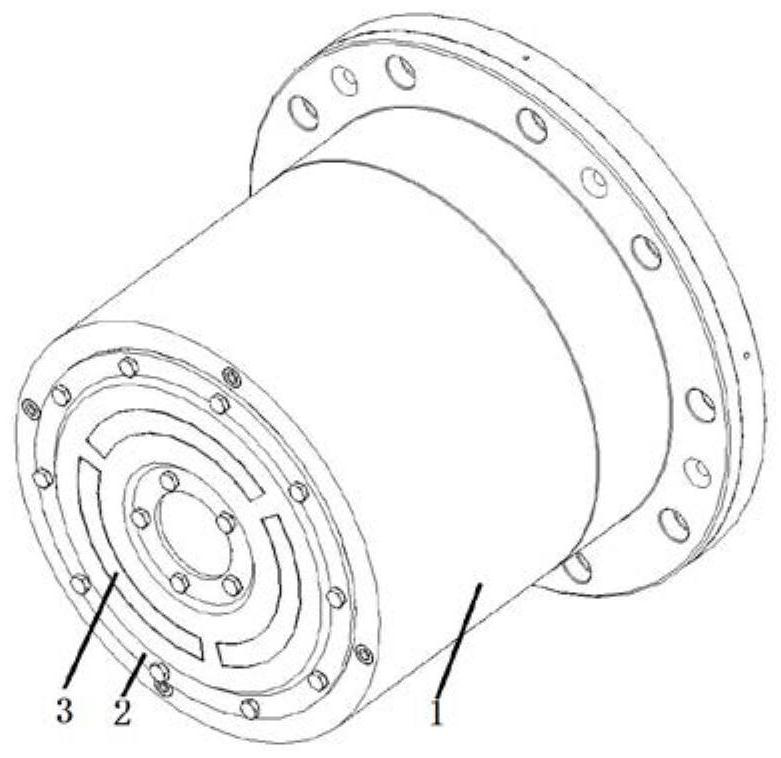

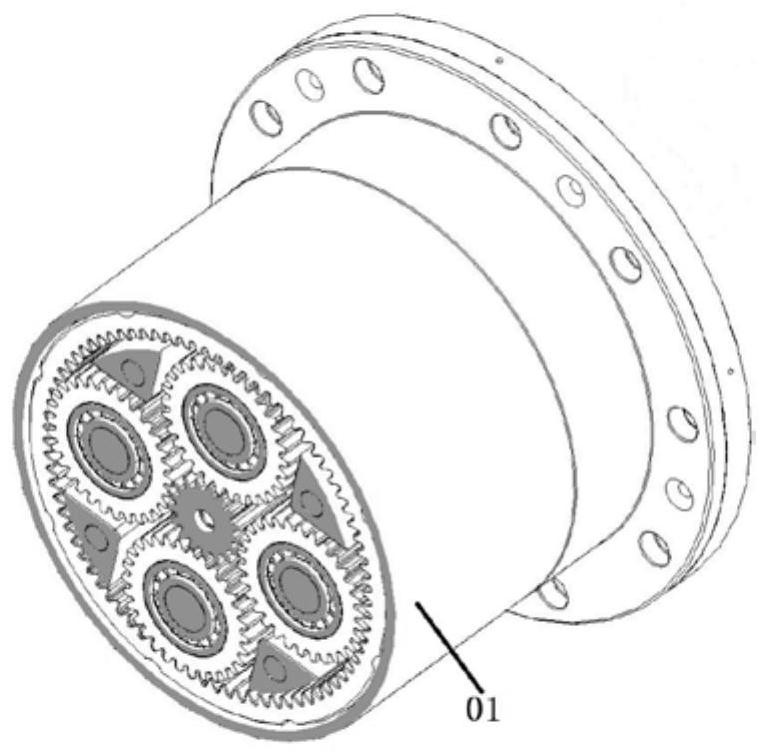

[0027] see Figure 1-5 , a planetary gear transmission, which includes a cylindrical housing 1 and a planetary gear 6, a sun gear 4, and an inner ring gear 5 located in the housing 1, and the planetary gear transmission also includes a set of the The oil level observation device on the end cover of the housing 1, the oil level observation device includes an outer cover plate 2 and an inner transparent plate 3, the outer cover plate 2 is provided with a hollow arc 2c, and the hollow arc 2c The center of circle is located at the rotation center of the planetary gear transmission, the inner transparent plate 3 is located between the outer cover plate 2 and the end cover, and the inner transparent plate 3 completely covers the hollow arc 2c, There is an oil level indicating cavity 8 for observing the oil level between the inner transparent plate 3 and the end cover, and the oil level indicating cavity 8 is connected to the inside of the housing 1 through the oil filter provided on...

Embodiment 2

[0036] The difference from the above-mentioned embodiment 1 is that the hollow arc 2c in the embodiment 1 is replaced by a hollow ring, and the outer cover plate 2 includes a split outer ring cover plate and an inner ring cover plate, and the outer ring cover plate and the inner ring cover plate are separated. There is the hollow ring between the inner ring cover plates.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com