Water hammer wave protection method for blasting demolition of seepage-proofing pile of reinforced concrete water-retaining cofferdam

A reinforced concrete and water shock wave technology, which is applied in the safety protection of underwater anti-seepage pile blasting and water shock wave protection in the blasting demolition of water-retaining cofferdam anti-seepage piles. Wave strength, water shock wave strength and other problems, to achieve the effect of simple operation, scientific and reasonable design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

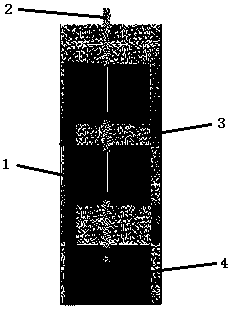

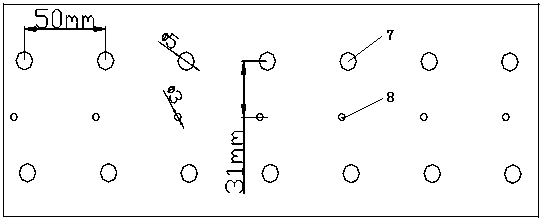

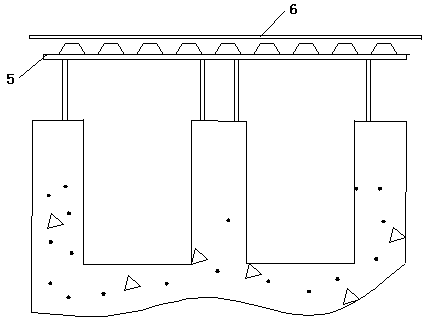

[0024] refer to Figure 1-3 , the present invention will be further explained below in conjunction with specific embodiment.

[0025] The embodiment selects a reinforced concrete water-retaining cofferdam anti-seepage pile that needs to be demolished by blasting. The parameters of the reinforced concrete water-retaining cofferdam anti-seepage pile are: the anti-seepage pile is a reinforced concrete structure with a diameter of Φ950 mm, the center is a steel pipe of Φ114, and a steel cage The width of the pile is 400 mm, and the length is 780 mm. Two U-shaped steel bars are lapped at the pile end and the pile bottom, and the piles are superimposed on each other. The horizontal length of the pre-demolished pile row is 33.75 m.

[0026] A water shock wave protection method for blasting demolition of reinforced concrete water retaining cofferdam anti-seepage piles proposed by the present invention comprises the following steps:

[0027] S1, blasthole parameters include: the numbe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com