Device and method for testing bonding strength of rivet type multilayer electrical contact

A testing device and bonding strength technology, applied in the direction of measuring device, strength characteristics, and testing the strength of materials by applying stable tension/pressure. The effect of good scientific research application value, credible principle and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

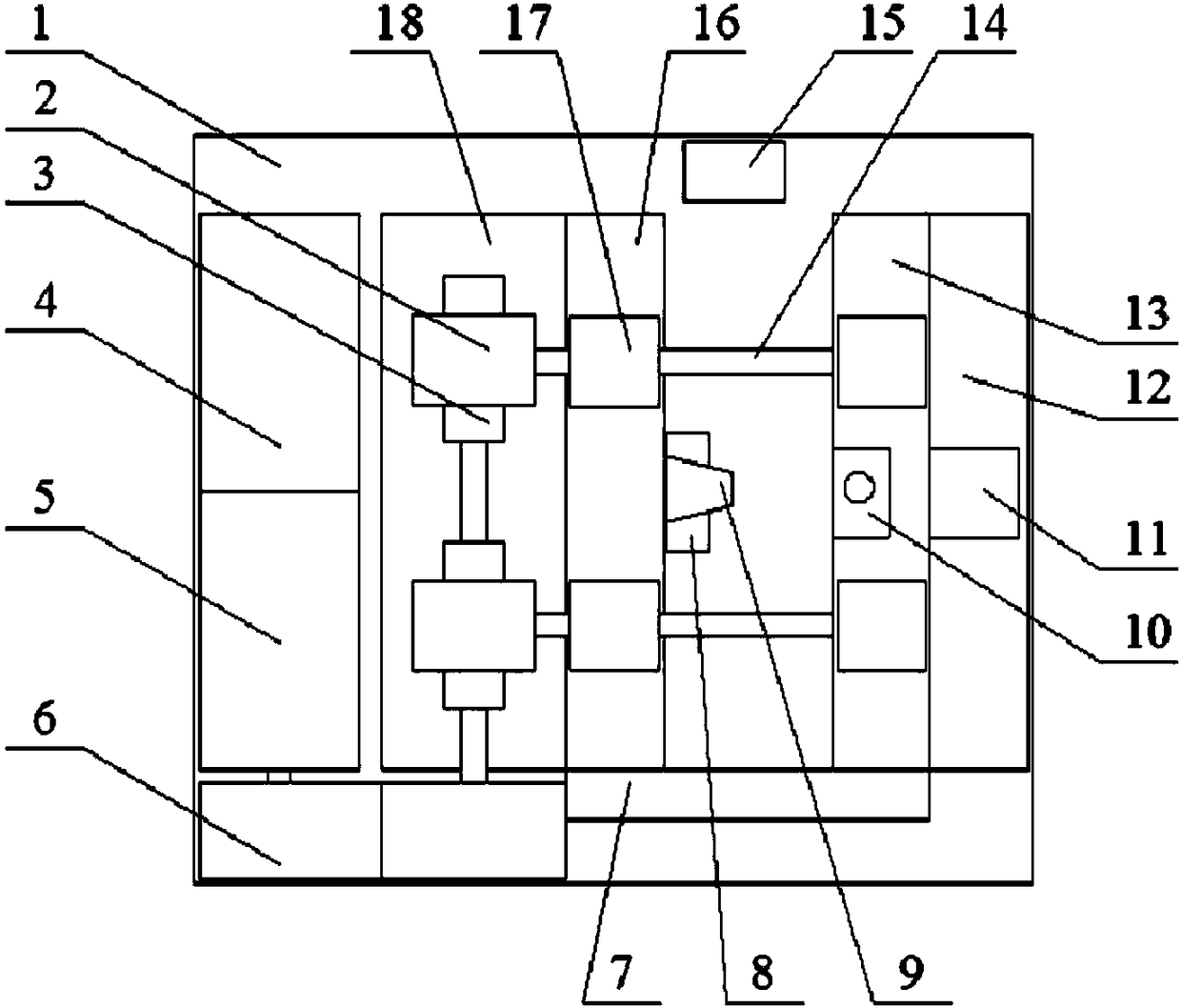

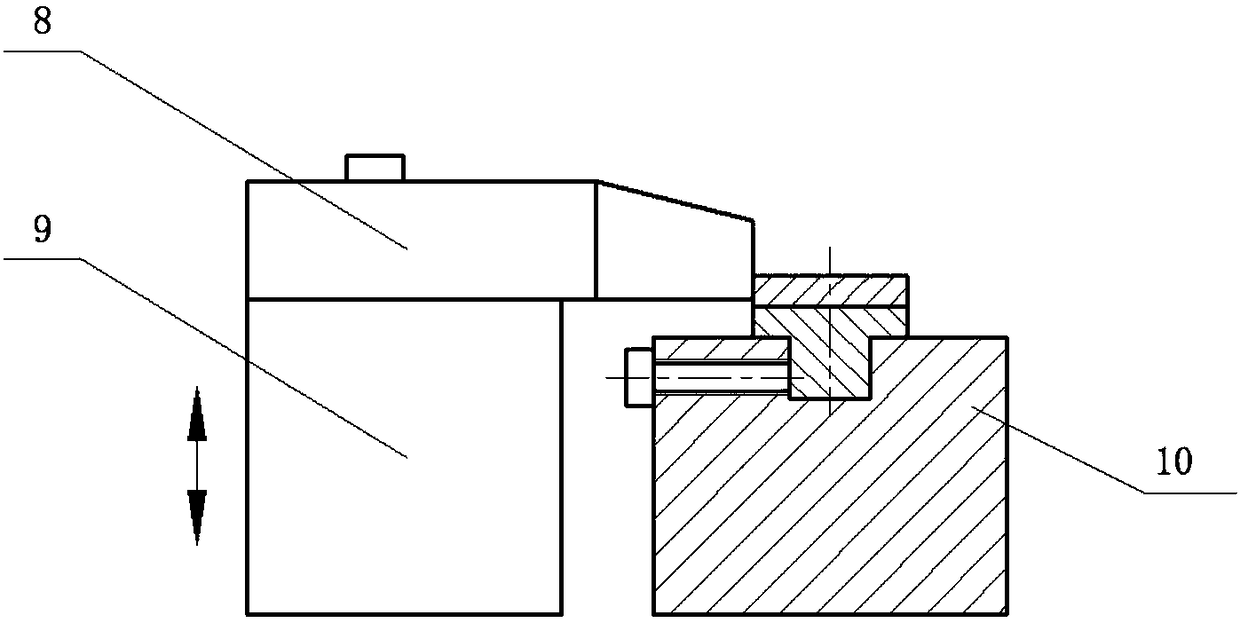

[0023] Specific implementation mode one: as Figure 1~3 As shown, the rivet-type multilayer electrical contact bonding strength testing device of this embodiment includes a base 1, two worm wheels 2, two worms 3, a motor 4, a reducer 5, two gears 6, an encoder 7, a pusher Head 8, electric lifting slide table 9, fixture 10, force sensor 11, support seat 12, first screw support 13, two bidirectional lead screws 14, industrial camera 15, second screw support 16, four nuts 17 and a fixed seat 18; the motor 4 and the reducer 5 constitute the driving unit, the two gears 6 constitute the transmission unit, the electric lifting slide table 9, two two-way lead screws 14 and the industrial camera 15 constitute the test unit, the push head 8 and the fixture 10 The test piece fixture is constituted, the encoder 7 and the force sensor 11 constitute the test unit, and the two gears 6 are composed of a driving gear and a driven gear; the driving unit, the fixed seat 18, the second screw supp...

specific Embodiment approach 2

[0025] Specific implementation mode two: as figure 1 As shown, the base 1 of this embodiment is a rectangular plate base. Such design is convenient for processing and making. Other components and connections are the same as those in the first embodiment.

specific Embodiment approach 3

[0026] Specific implementation mode three: as figure 1 As shown, in this embodiment, the push head 8 is located in the middle of the second screw support 16 , and the clamp 10 is located in the middle of the first screw support 13 . Such a design can ensure the centering of the test piece during the movement of the test device in the opposite direction or backward direction, and at the same time, the present invention has the characteristics of large working force and compact structure. Other compositions and connections are the same as those in Embodiment 1 or 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com