Method for measuring backfilling ratio of reconstituted cut stem products

A measuring method and technology for cut stems are applied in the field of measuring the backfill rate of reconstituted cut stems, which can solve the problem that the backfilling effect cannot be directly detected, and achieve the effects of high result accuracy, uniform moisture distribution, and improved accuracy.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

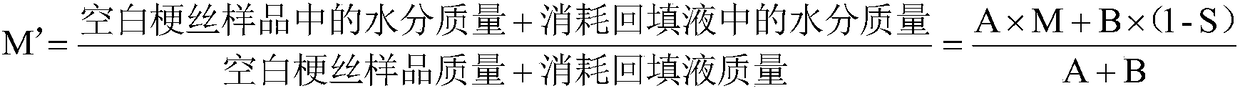

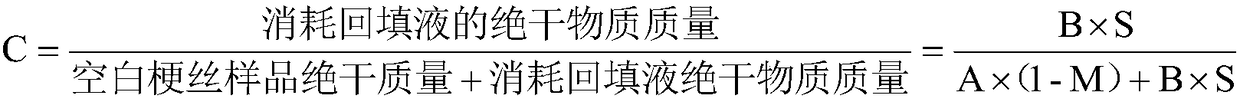

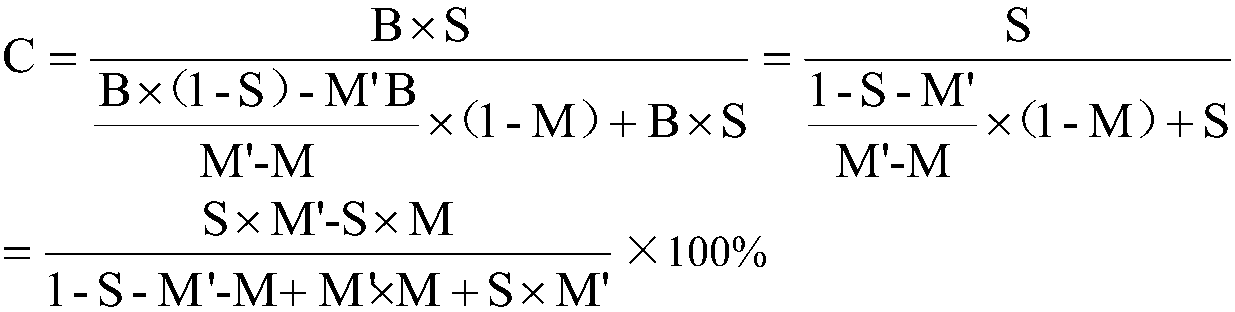

Method used

Image

Examples

Embodiment 1

[0032] A method for measuring the backfill rate of reconstituted shredded stem products, comprising the following steps:

[0033] (1) First take a certain amount of blank cut stem samples before backfilling and backfill cut stem samples and place them in sealed bags respectively, mix the samples evenly in the sealed bags, and then measure the blank cut stem samples before backfilling and the cut stem samples after backfilling. The moisture content of the cut stem samples were 27.8% and 46.3%, respectively. The blank cut stem samples before backfilling were the unfilled cut stem samples before backfilling the feeder on the reconstituted cut stem production line, and the backfilled cut stem samples were the reconstituted cut stem cut production line samples. Shredded stems after backfilling feeder;

[0034] (2) Get a certain amount of backfill liquid sample, the mass concentration that records backfill liquid sample is 38.1%; Mass concentration is the percentage ratio that absol...

Embodiment 2

[0047] A method for measuring the backfill rate of reconstituted shredded stem products, comprising the following steps:

[0048] (1) First take a certain amount of blank cut stem samples before backfilling and backfill cut stem samples and place them in sealed bags respectively, mix the samples evenly in the sealed bags, and then measure the blank cut stem samples before backfilling and the cut stem samples after backfilling. The moisture content of the cut stem samples were 26.3% and 44.2%, respectively. The blank cut stem samples before backfilling were the unfilled cut stem samples before the backfill feeder on the reconstituted cut stem production line, and the backfilled cut stem samples were the reconstituted cut stem cut production line samples. Shredded stems after backfilling feeder;

[0049] (2) Get a certain amount of backfill liquid sample, and record the mass concentration of the backfill liquid sample as 38.4%; The mass concentration is the percentage ratio of a...

Embodiment 3

[0062] A method for measuring the backfill rate of reconstituted shredded stem products, comprising the following steps:

[0063] (1) First take a certain amount of blank cut stem samples before backfilling and backfill cut stem samples and place them in sealed bags respectively, mix the samples evenly in the sealed bags, and then measure the blank cut stem samples before backfilling and the cut stem samples after backfilling. The moisture content of the cut stem samples were 27.3% and 45.1%, respectively. The blank cut stem samples before backfilling were the unfilled cut stem samples before backfilling the feeding machine on the reconstituted cut stem production line, and the backfilled cut stem samples were the reconstituted cut stem cut production line samples. Shredded stems after backfilling feeder;

[0064] (2) Get a certain amount of backfill liquid sample, and record the mass concentration of the backfill liquid sample as 40.6%; The mass concentration is the percentag...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com