Manual and automatic integrated wire calibrating system and method of electrical equipment

A technology for electrical equipment and electrical secondary equipment, applied in the direction of measuring electricity, measuring electrical variables, instruments, etc., can solve the application report of the finished device of the manual-automatic integrated alignment system, increase labor and equipment cost, attention Inconsistency and other problems, to achieve the effect of strengthening the flexibility and scalability of use, reducing the complexity of wiring, and simplifying the hardware circuit

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0046] The present invention will be further described in detail below in conjunction with specific embodiments, which are explanations of the present invention rather than limitations.

[0047] The invention has high alignment efficiency, diversified judgment basis, can reduce labor cost, and improves detection accuracy, and is applicable to the technical field of electrical equipment transformation, maintenance and newly-built alignment.

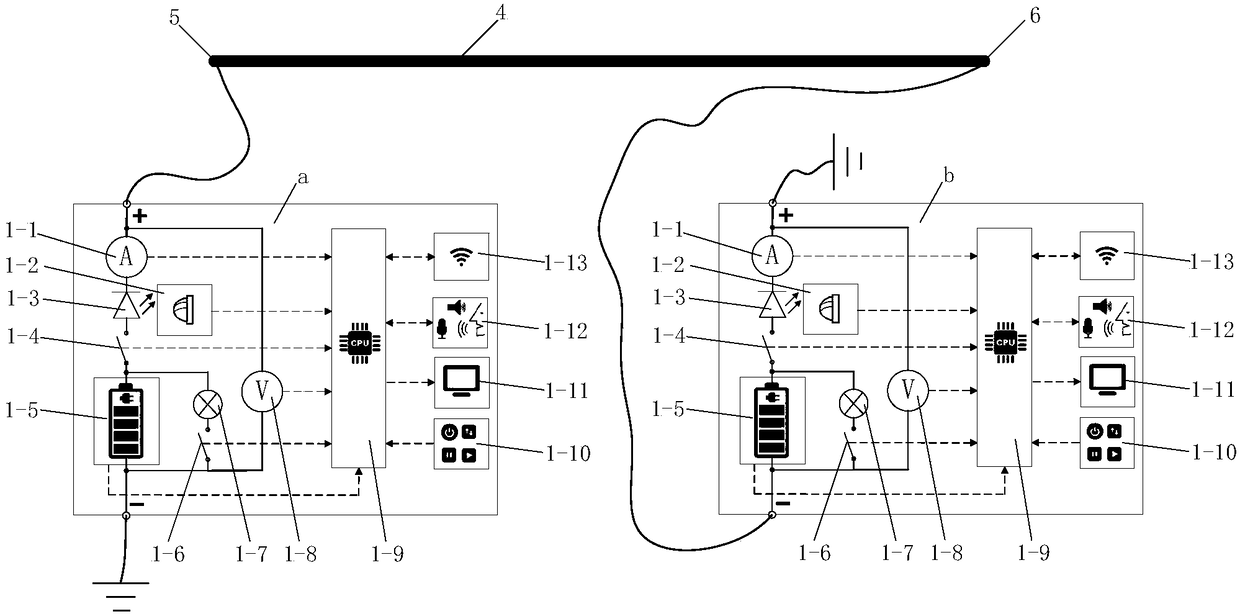

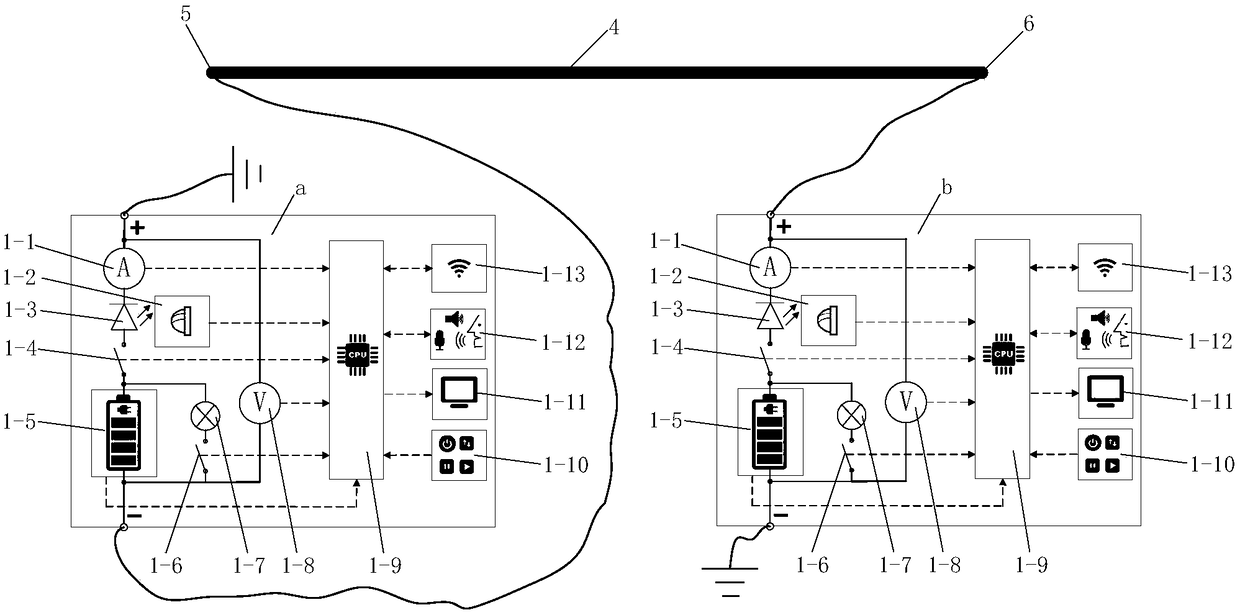

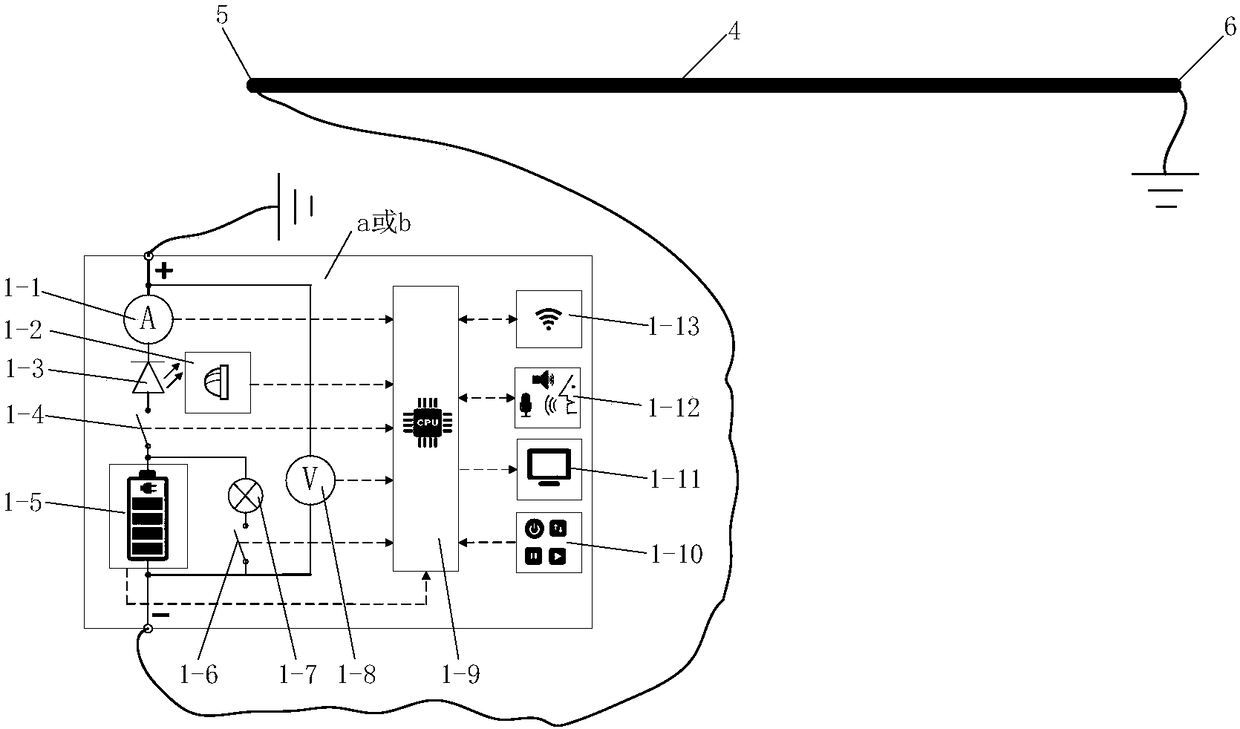

[0048] The present invention includes two identical first calibration module a and second calibration module b; wherein, the positive or negative polarity output port of the first calibration module a is connected to the electrical equipment side to be calibrated, and the first calibration module a The remaining polarity output port of line module a is connected to the ground wire; the second line calibration module b selects the opposite polarity output port of the first line calibration module a and the line to be calibrated to connect to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com