A Method for Analyzing the Vibration Environment of Sensing Part of Engine and Determining Test Load

A determination method and engine technology, applied in computer-aided design, design optimization/simulation, calculation, etc., can solve the problems of high design and production costs, low service life, etc., to make up for unscientific, improve reliability and economy , good versatility and practical effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

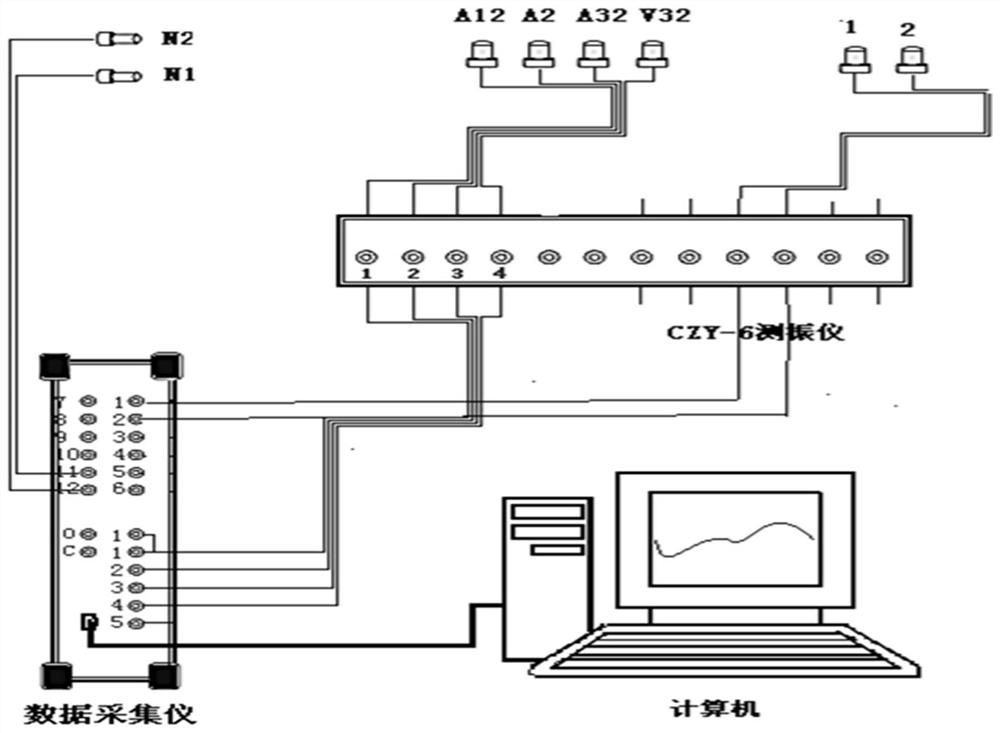

[0023] The present invention will be described in further detail below in conjunction with the accompanying drawings.

[0024] The method for analyzing the vibration environment of the sensing part of the engine and determining the test load of the present invention comprises the following steps:

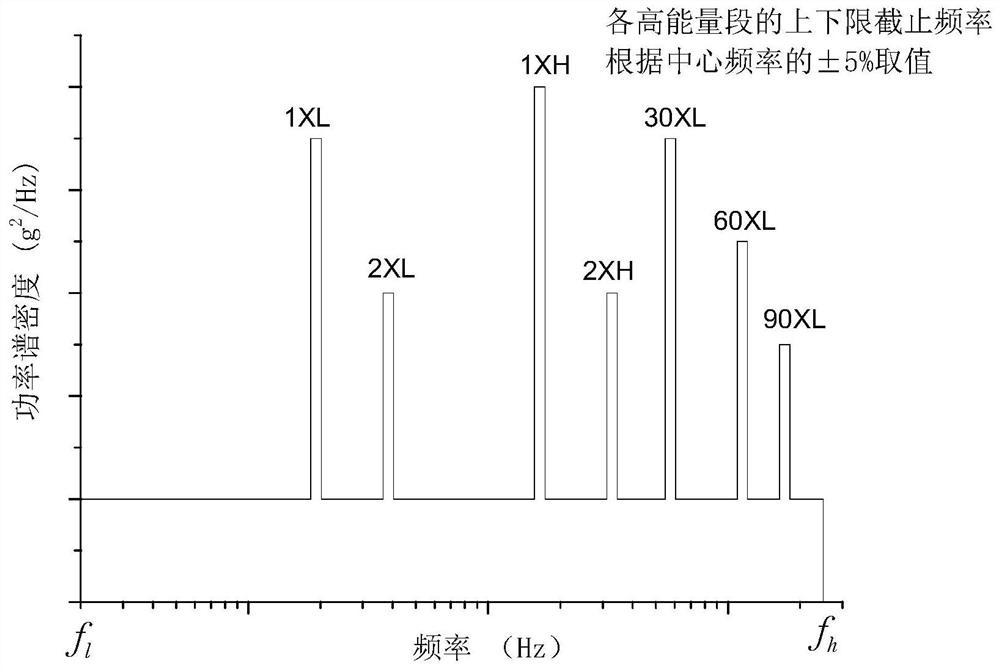

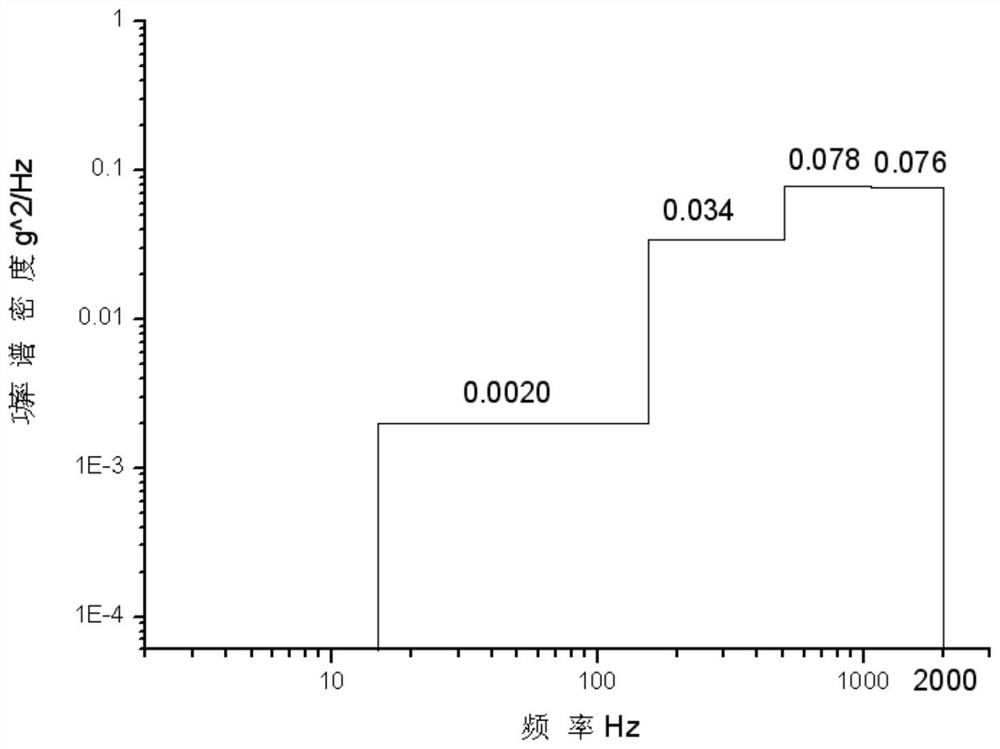

[0025] 1. Calculate and analyze the static strength and fatigue strength of the affected part. According to the design requirements of the sensing part and the temperature and pressure parameters of the installation part, the maximum stress and the maximum stress position of the sensing part are calculated by establishing the calculation model of the sensing part and the constraint conditions of the sensing part by using the finite element calculation method. At the same time, according to the rotational speed of the engine in each state, the excitation frequency margin of the natural frequency of each order in each state of the sensing part is calculated, and the resonance point is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com