Integrated process method of host heel block and ventilating box

A process method and ventilation box technology, applied in cooling/ventilation devices, wind power generation, electromechanical devices, etc., can solve the problems of large cooler size, failure to meet the requirements of the type test of the manufacturer, and insufficient space for the ventilation box layout, etc., to achieve Sufficient space in the ventilation circuit, effective external foreign matter, and easy to clean foreign matter

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

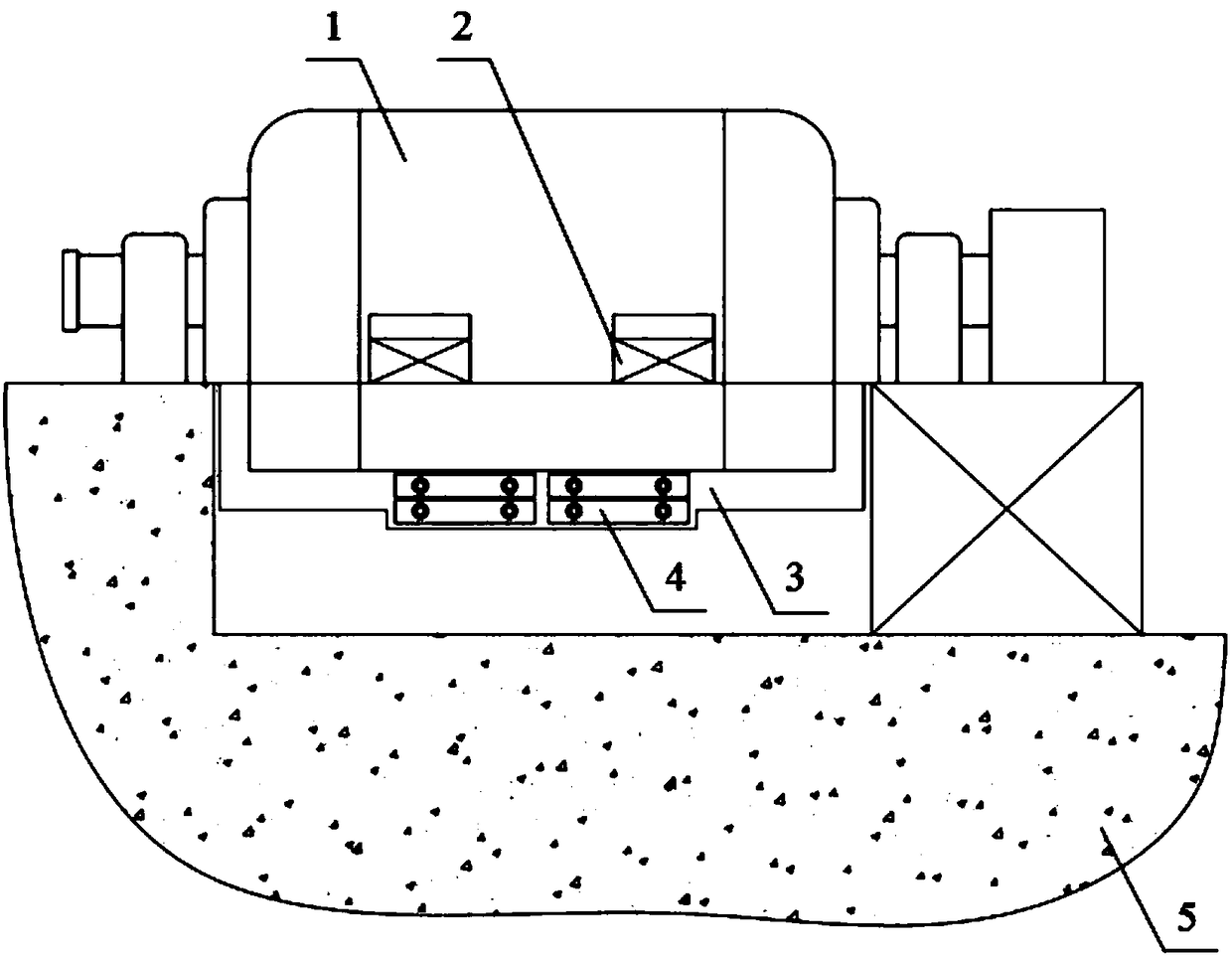

[0027] like figure 1 As shown, the air-cooled turbo-generator 1 manufacturer type-tests the layout of the traditional main engine block 2 and the ventilation box 3. The turbo-generator 1 is placed on four traditional main engine blocks 2 and manufactured under the turbo-generator 1. A ventilation box 3, a small cooler 4 is placed in the ventilation box 3. The installation foundation of the turbo-generator 1 is less stable than the foundation of the power plant. The temporarily constructed ventilation box 3 has the problems of narrow ventilation circuit and insufficient air volume.

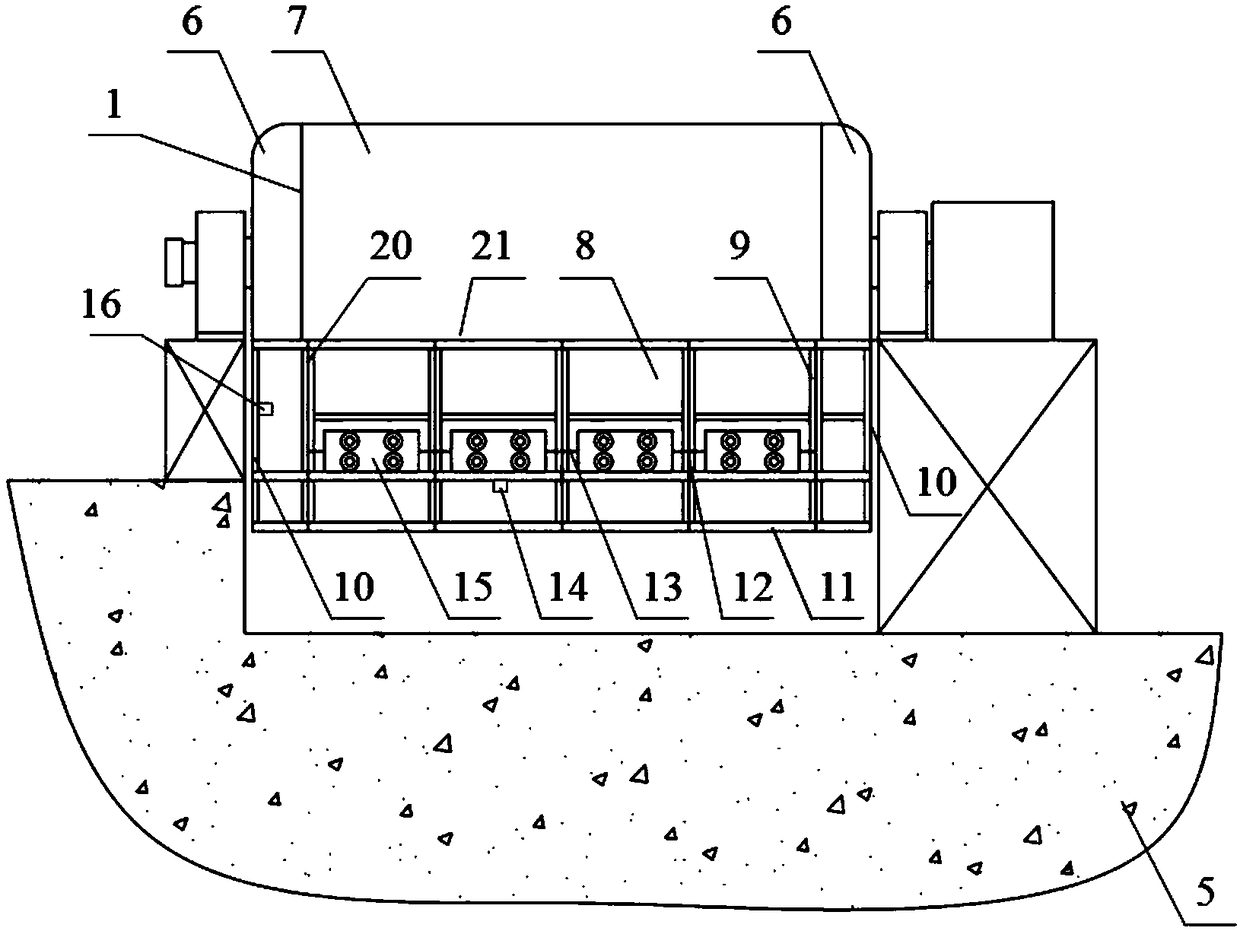

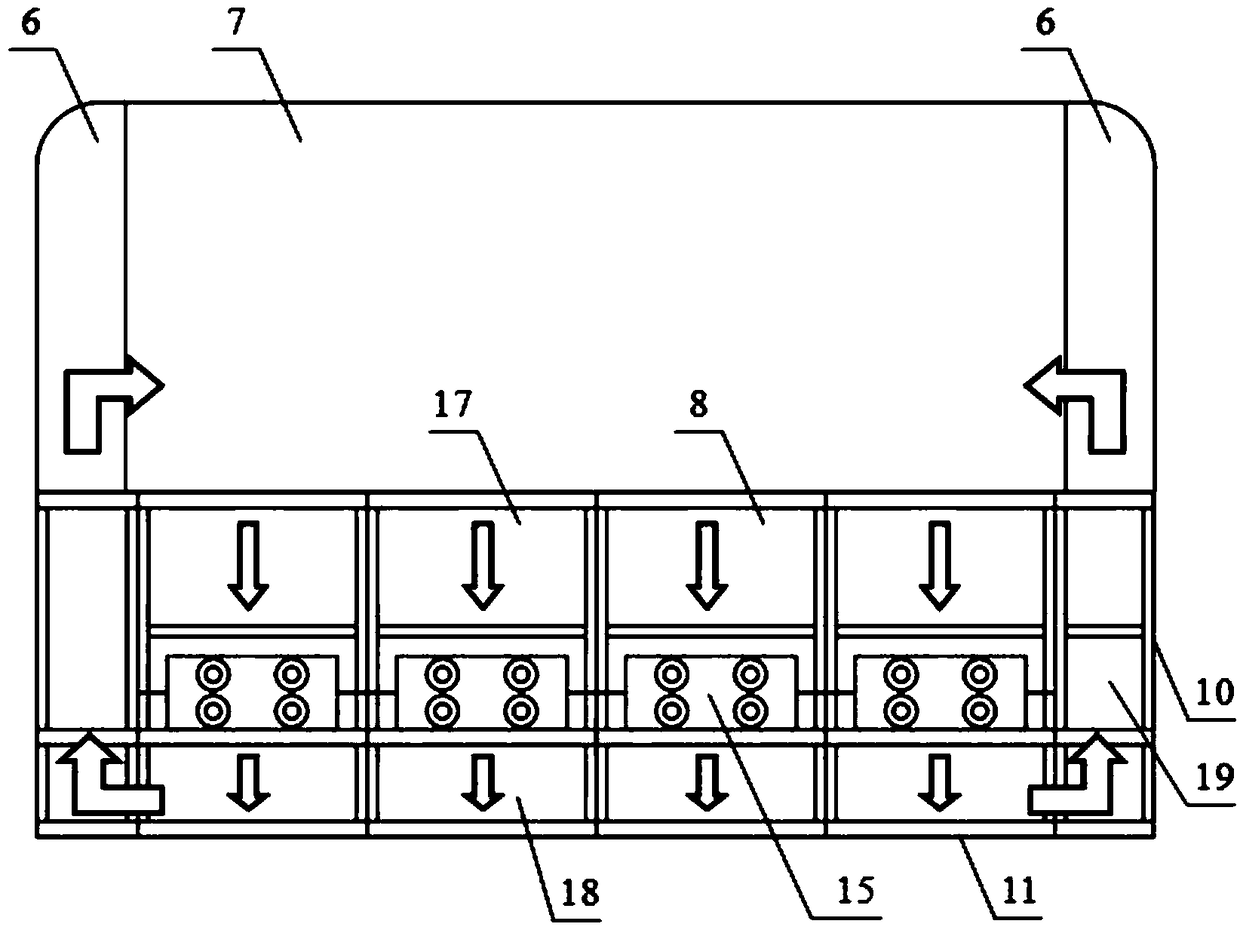

[0028] like figure 2 As shown, the large-scale air-cooled turbogenerator 1 manufacturer type test main engine block 8 and the integrated arrangement of the ventilation box 3 of the present invention are applied. Arrange twelve host pads 8 on the test platform 5, and install the bottom plate 11, support beam 12, cooler 15, first windshield 13, second windshield 9, wallboard 10, and wind temperat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com